Efficient non-oxidizing bactericide and preparation method thereof

A non-oxidizing, fungicide technology, applied in the fields of botanical equipment and methods, biocides, disinfectants, etc., can solve the problems of rising water treatment costs, large increase in the amount of chemicals and new water, and unsatisfactory effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

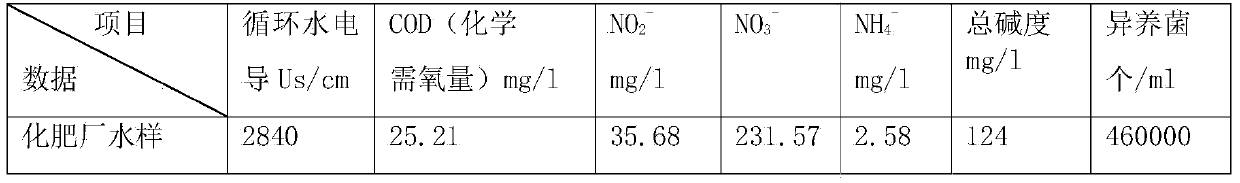

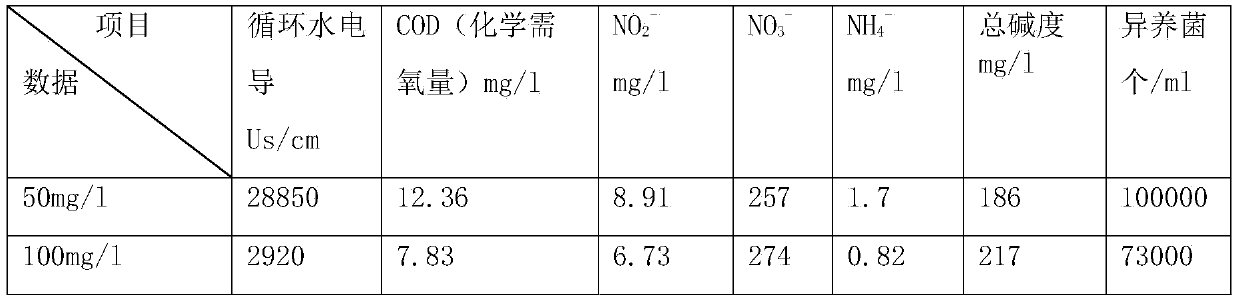

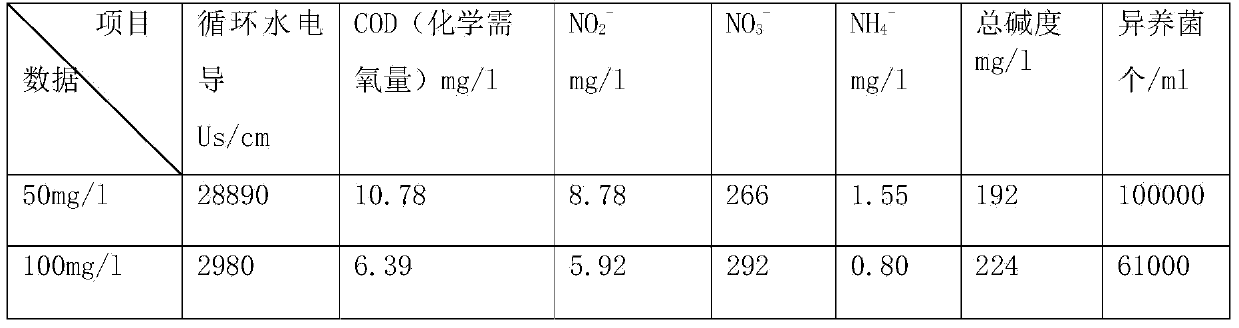

Image

Examples

Embodiment 1

[0028] 1) Take 4 parts of maleic anhydride, 5 parts of sec-octanol, and 4 parts of p-toluenesulfonic acid, put them into the reaction kettle, stir at 60rpm, pass steam into the interlayer to heat the material to 130°C for esterification, and keep the temperature constant 2h;

[0029] 2) After constant temperature for 2 hours, turn off the heating steam, lower the temperature of the material to 103°C, add 5 parts of sodium bisulfite for sulfonation and stir while feeding, control the pH value to 8.0, and the reaction time is 5 hours;

[0030] 3) After reacting for 5 hours, turn off the heating steam completely, pass in cooling water, and after lowering the material temperature to 20°C, add 20 parts of sodium dimethyldithiocarbamate, 5 parts of biodispersant 508, and 15 parts of hydroxypropyl methacrylate Esters and 27 parts of desalted water, stirred evenly, filtered through 200 mesh and packaged.

Embodiment 2

[0032] 1) Take 4 parts of maleic anhydride, 5 parts of sec-octanol, and 4 parts of p-toluenesulfonic acid, put them into the reaction kettle, stir at 70rpm, pass steam into the interlayer to heat the material to 120°C for esterification, and Constant temperature 2h;

[0033] 2) After constant temperature for 2 hours, turn off the heating steam, lower the temperature of the material to 100°C, add 6 parts of sodium bisulfite for sulfonation, stir while adding the material, control the pH value to 9.5, and the reaction time is 5 hours;

[0034] 3) After reacting for 5 hours, turn off the heating steam completely, pass in cooling water, and after lowering the material temperature to 20°C, add 25 parts of sodium dimethyl dithiocarbamate, 15 parts of biodispersant 508, and 15 parts of hydroxypropyl methacrylate Esters and 16 parts of desalted water, stirred evenly, filtered through 200 mesh and packaged.

Embodiment 3

[0036] 1) Take 4 parts of maleic anhydride, 5 parts of sec-octanol, and 4 parts of p-toluenesulfonic acid, put them into the reaction kettle, stir at 80rpm, pass steam into the interlayer to heat the material to 140°C for esterification, And constant temperature 2h;

[0037] 2) After constant temperature for 2 hours, turn off the heating steam, lower the temperature of the material to 105°C, add 7 parts of sodium bisulfite for sulfonation, stir while adding the material, control the pH value to 7.0, and the reaction time is 5 hours;

[0038] 3) After reacting for 5 hours, turn off the heating steam completely, pass in cooling water, and after lowering the material temperature to 20°C, add 30 parts of sodium dimethyldithiocarbamate, 10 parts of biodispersant 508, and 10 parts of hydroxypropyl methacrylate Esters and 17 parts of desalted water, stirred evenly, filtered through 200 mesh and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com