Brown lactobacillus beverage and preparation method thereof

A lactic acid bacteria beverage, brown technology, applied in dairy products, milk preparations, applications, etc., can solve problems such as inducing high blood pressure, aggravating gastrointestinal burden, and being unhealthy, achieving the effect of rich nutritional value and reducing metabolic burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

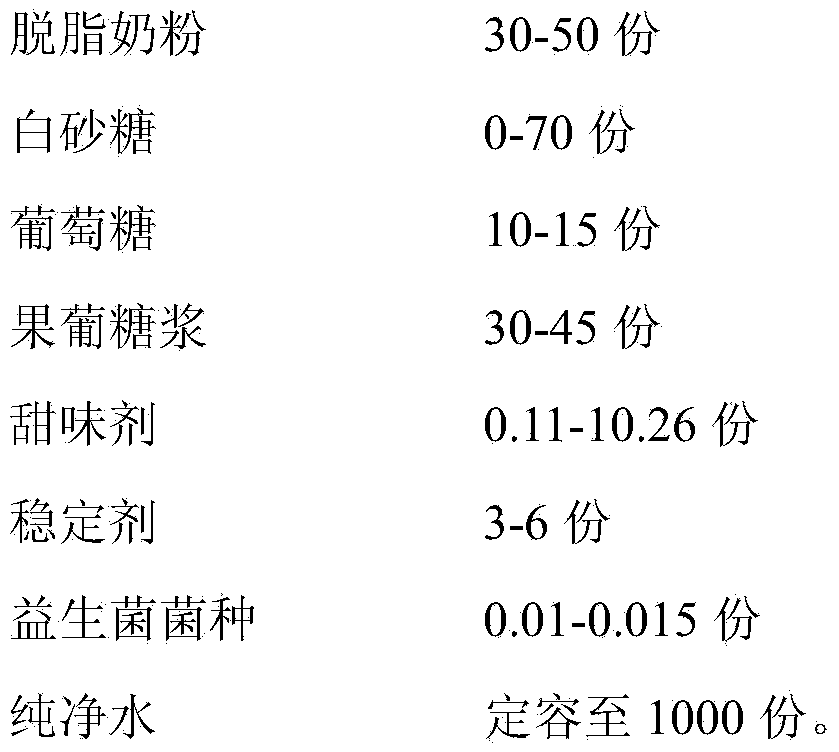

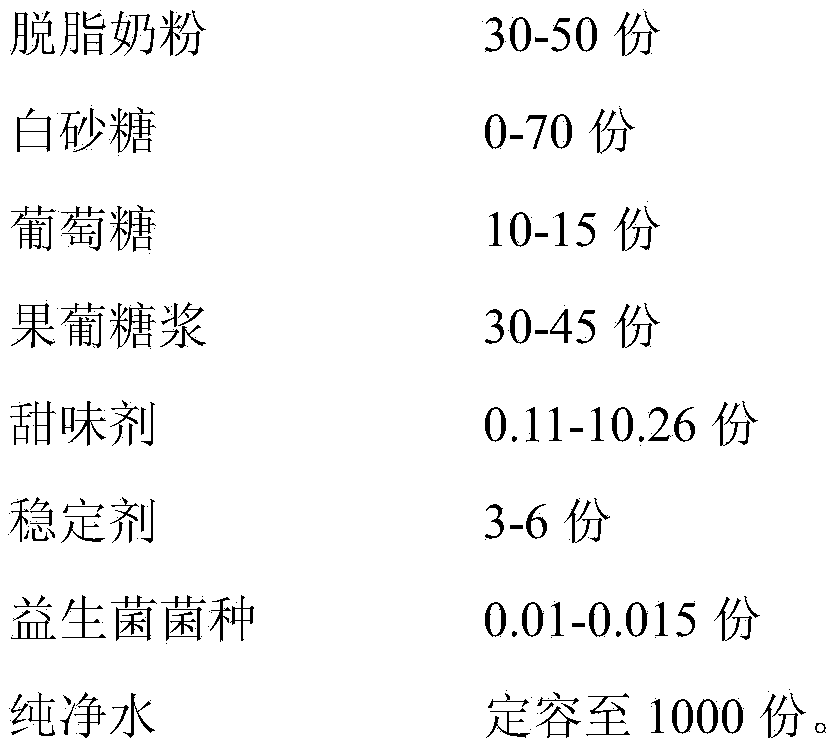

[0049] Raw materials include: 30kg of skimmed milk powder, 70kg of white sugar, 10kg of glucose, 30kg of fructose syrup, 5kg of erythritol, 0.05kg of stevia, 3kg of pectin, 10g of probiotic strains (Lactobacillus casei and Lactobacillus paracasei), Dilute pure water to 1000kg.

[0050] (1) Ingredients for fermented milk: heat up purified water to 40°C, dissolve skimmed milk powder, glucose, and 9kg fructose syrup in purified water, and set the volume to 250 parts;

[0051] (2) Hydration: The prepared fermented milk feed solution is left to stand for hydration at 40°C for 30 minutes;

[0052] (3) Homogenization: After hydration, the feed liquid is heated to 55°C and homogenized under a pressure of 18Mpa;

[0053] (4) Browning: Keep the homogenized feed liquid at 95°C for 3 hours for browning;

[0054] (5) Sterilization: Sterilize the feed liquid at the same time during the browning process;

[0055] (6) Inoculation: Cool down the sterilized feed liquid to the inoculation tem...

Embodiment 2

[0064] Raw materials include: 40kg of skimmed milk powder, 50kg of white sugar, 13kg of glucose, 38kg of fructose syrup, 55g of AK sugar, 55g of aspartame, 2kg of pectin, 2kg of soluble soybean polysaccharide, and 14g of probiotic strains (Lactobacillus plantarum).

[0065] (1) Ingredients for fermented milk: heat up purified water to 50°C, dissolve skimmed milk powder, glucose, and 19kg fructose syrup in purified water, and set the volume to 250 parts;

[0066] (2) Hydration: Leave the prepared fermented milk liquid at 50°C for 50 minutes to hydrate;

[0067] (3) Homogenization: After hydration, the feed liquid is heated to 60°C and homogenized under a pressure of 20Mpa;

[0068] (4) Browning: Keep the homogenized feed liquid at 98°C for 2 hours for browning;

[0069] (5) Sterilization: Sterilize the feed liquid at the same time during the browning process;

[0070] (6) Inoculation: Cool the sterilized feed liquid to the inoculation temperature of 39°C, inoculate and inoculat...

Embodiment 3

[0079] Raw materials include: skimmed milk powder 50kg, white sugar 0kg, glucose 15kg, fructose syrup 45kg, erythritol 10kg, stevia 0.1kg, AK sugar 80g, aspartame 80g, pectin 2kg, soluble soybean polysaccharide 4kg, prebiotic Bacteria strain (Lactobacillus casei) 15g.

[0080] (1) Ingredients for fermented milk: heat up purified water to 45°C, dissolve skimmed milk powder, glucose, and 15kg fructose syrup in purified water, and set the volume to 250 parts;

[0081] (2) Hydration: Leave the prepared fermented milk liquid at 45°C for 40 minutes for hydration;

[0082] (3) Homogenization: After hydration, the feed liquid is heated to 57°C and homogenized under a pressure of 19Mpa;

[0083] (4) Browning: Keep the homogenized feed liquid at 96°C for 2.5 hours for browning;

[0084] (5) Sterilization: Sterilize the feed liquid at the same time during the browning process;

[0085] (6) Inoculation: Cool down the sterilized feed liquid to the inoculation temperature of 36°C, inocul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com