Titanium dioxide/cadmium sulfide/titanium dioxide composite film and application thereof

A technology of titanium dioxide and composite thin films, applied in chemical/physical processes, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effects of improving catalytic efficiency, low cost, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Ultrasonic cleaning of the glass substrate 1 with acetone, alcohol, and deionized water one by one and drying;

[0029] (2) Fixing the pretreated glass substrate 1 on the sample stage of the electron beam evaporation coating machine;

[0030] (3) Titanium is used as the target material, and the target material is image 3 Medium solid matter 4 and molten matter 5, the chamber of the electron beam evaporation coating machine is pumped to 3×10 -8 ~5×10 -8 Torr's High Vacuum;

[0031] (4) Adjust the incident angle of the electron beam 6 from 3 to 85 degrees, and make the sample stage stand still or rotate at a rate of 10 rpm, and grow a 300nm thick titanium deposition film obliquely on the substrate 1 of the sample stage;

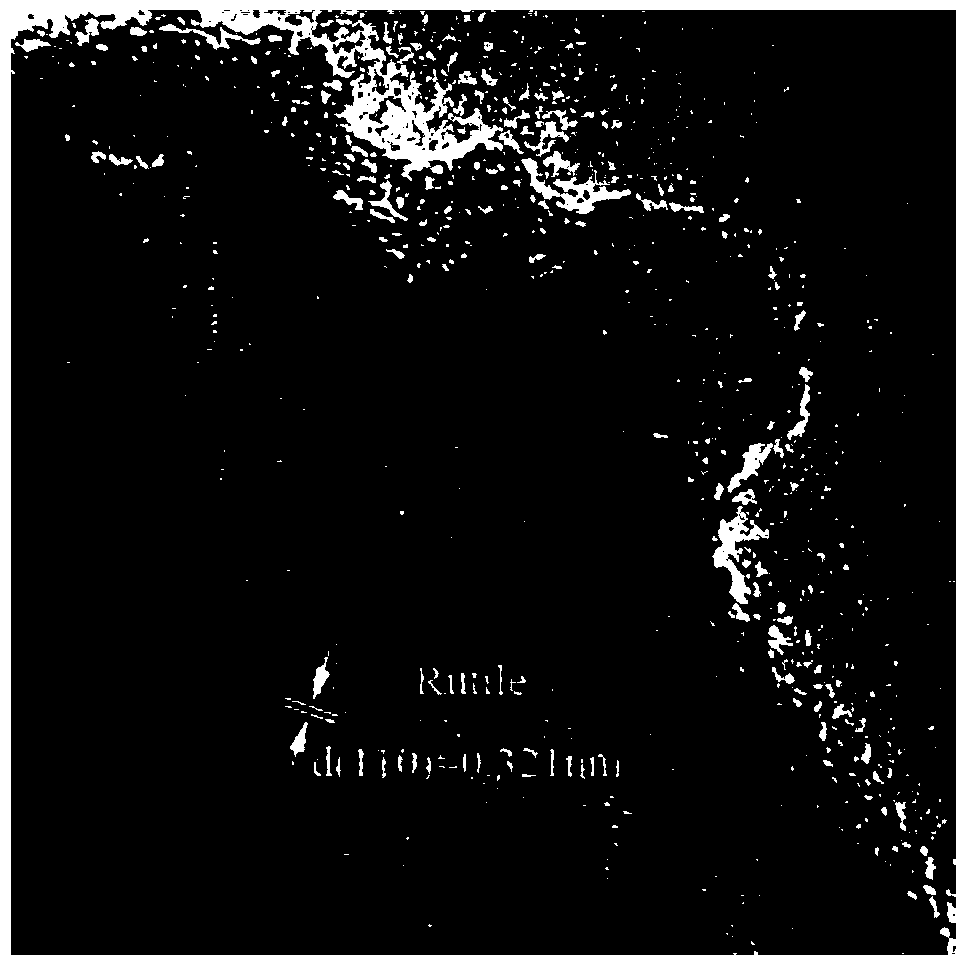

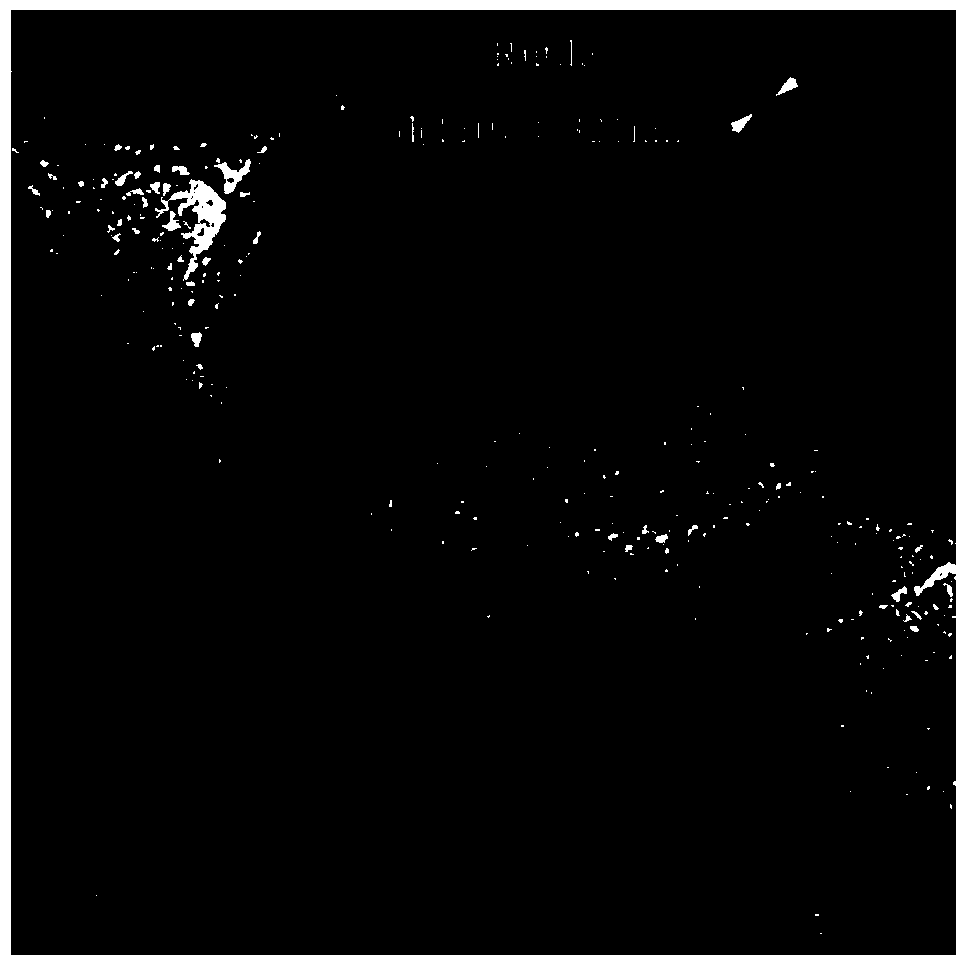

[0032] (5) Titanium dioxide nanorod array film was obtained by annealing the titanium nanorod array film at 450°C in air for 2 hours;

[0033] (6) Deposit cadmium sulfide nanoparticles on titanium dioxide nanorods by continuous ion layer adsorpt...

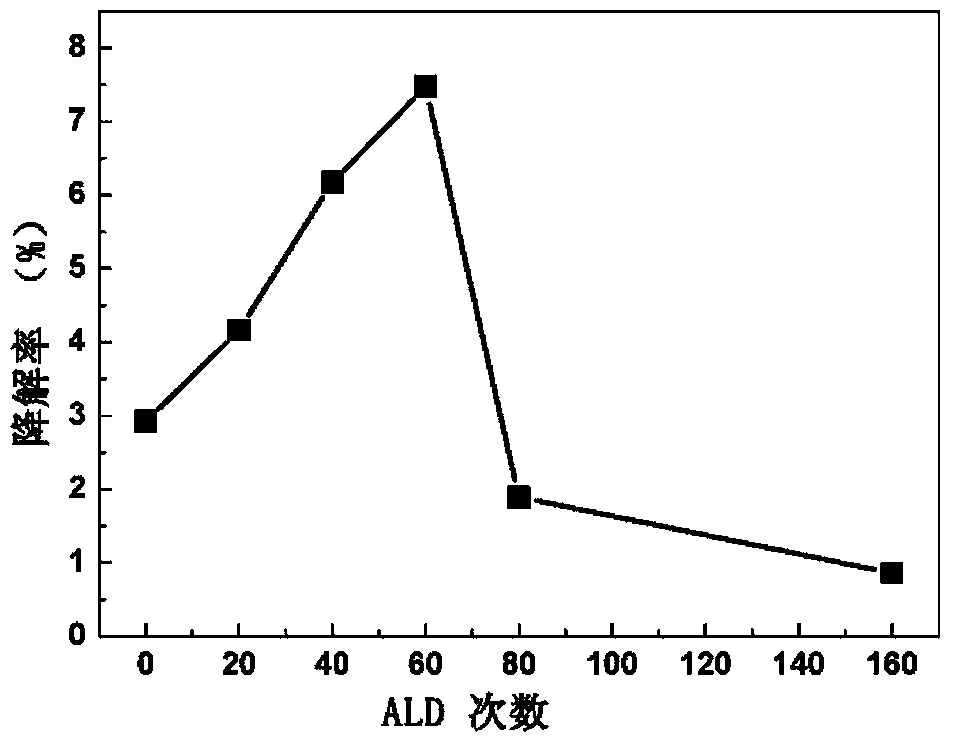

Embodiment 2

[0037] (1) Ultrasonic cleaning of the glass substrate 1 with acetone, alcohol, and deionized water one by one and drying;

[0038] (2) Fixing the pretreated glass substrate 1 on the sample stage of the electron beam evaporation coating machine;

[0039] (3) Titanium is used as the target material, and the target material is image 3 Medium solid matter 4 and molten matter 5, the chamber of the electron beam evaporation coating machine is pumped to 3×10 -8 ~5×10 -8 Torr's High Vacuum;

[0040] (4) Adjust the incident angle of the electron beam 6 from 3 to 85 degrees, and make the sample stage stand still or rotate at a rate of 10 rpm, and grow a 300nm thick titanium deposition film obliquely on the substrate 1 of the sample stage;

[0041] (5) Titanium dioxide nanorod array film was obtained by annealing the titanium nanorod array film at 450°C in air for 2 hours;

[0042] (6) Deposit cadmium sulfide nanoparticles on titanium dioxide nanorods by continuous ion layer adsorpt...

Embodiment 3

[0046] (1) Ultrasonic cleaning of the glass substrate 1 with acetone, alcohol, and deionized water one by one and drying;

[0047] (2) Fixing the pretreated glass substrate 1 on the sample stage of the electron beam evaporation coating machine;

[0048] (3) Titanium is used as the target material, and the target material is image 3 Medium solid matter 4 and molten matter 5, the chamber of the electron beam evaporation coating machine is pumped to 3×10 -8 ~5×10 -8 Torr's High Vacuum;

[0049] (4) Adjust the incident angle of the electron beam 6 from 3 to 85 degrees, and make the sample stage stand still or rotate at a rate of 10 rpm, and grow a 300nm thick titanium deposition film obliquely on the substrate 1 of the sample stage;

[0050] (5) Titanium dioxide nanorod array film was obtained by annealing the titanium nanorod array film at 450°C in air for 2 hours;

[0051] (6) Deposit cadmium sulfide nanoparticles on titanium dioxide nanorods by continuous ion layer adsorpt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com