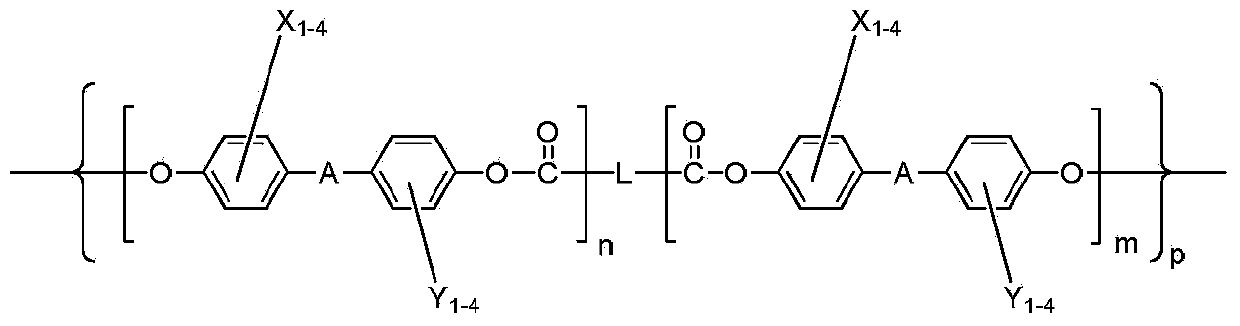

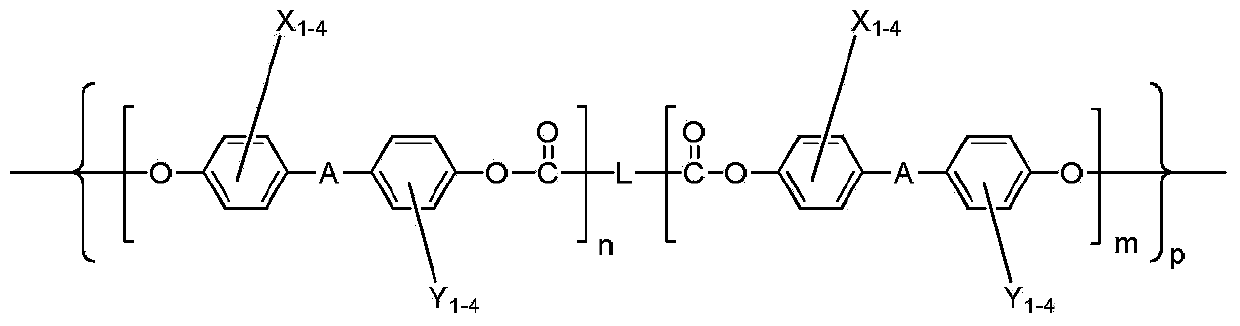

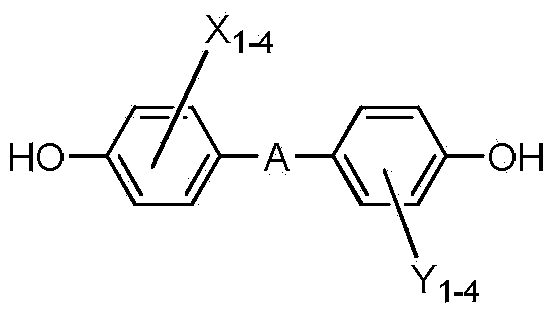

Aromatic polycarbonate and preparation method thereof

A polycarbonate and aromatic technology, applied in the field of aromatic polycarbonate and its preparation, can solve the problems of product mechanical properties change, product qualification rate reduction, free volume reduction, etc., to reduce the brittleness change of resin annealing treatment, The effect of improving flexibility and athletic ability, improving usability and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Mix 200g of BPA, 1000g of water, 240g of 30% NaOH solution, 0.12g of hydrosulfite, 0.45g of diethylene glycol, and 2000g of dichloromethane to dissolve all the BPA. Feed phosgene under stirring condition, the phosgene flow rate is controlled at 1.5-2.0g / min, and the pH is adjusted with 30% NaOH solution, and the pH is controlled to be 12-13. When the total amount of phosgene is 90.97g, stop the photochemical Add 3.35g of p-tert-butylphenol and 0.46g of triethylamine, stir until no acid chloride groups exist in the system, and continue stirring for 30min while maintaining the pH at 12-13. The water phase was separated and removed, the oil phase was acidified with hydrochloric acid solution to adjust the pH<3.0, the oil and water were separated again, the oil phase was washed with water until neutral, and the solid was collected by methanol precipitation. Product molecular weight is detected by GPC.

[0071] The solid obtained above was granulated and injected into corre...

Embodiment 2

[0073] Mix 200g of BPA, 1000g of water, 240g of 30% NaOH solution, 0.12g of hydrosulfite, and 2000g of dichloromethane to dissolve all the BPA. Feed phosgene under stirring condition, the phosgene flow rate is controlled at 1.5-2.0g / min, and the pH is adjusted with 30% NaOH solution, and the pH is controlled to be 12-13. When the total amount of phosgene is 90.97g, stop the photochemical Add 1.78g of diethylene glycol, 3.35g of p-tert-butylphenol, and 0.46g of triethylamine, stir until no acid chloride groups exist in the system, and continue stirring for 30min while maintaining the pH at 12-13. The water phase was separated and removed, the oil phase was acidified with hydrochloric acid solution to adjust the pH<3.0, the oil and water were separated again, the oil phase was washed with water until neutral, and the solid was collected by methanol precipitation. Product molecular weight is detected by GPC.

[0074] The solid obtained above was granulated and injected into corr...

Embodiment 3

[0076]Mix 200g of BPA, 1000g of water, 240g of 30% NaOH solution, 0.12g of hydrosulfite, 0.33g of triethylene glycol, and 2000g of dichloromethane to dissolve all the BPA. Feed phosgene under stirring condition, the phosgene flow rate is controlled at 1.5-2.0g / min, and the pH is adjusted with 30% NaOH solution, and the pH is controlled to be 12-13. When the total amount of phosgene is 90.97g, stop the photochemical Add 1.34g of p-tert-butylphenol and 0.46g of triethylamine, stir until no acid chloride groups exist in the system, and continue stirring for 30min while maintaining the pH at 12-13. The water phase was separated and removed, the oil phase was acidified with hydrochloric acid solution to adjust the pH<3.0, the oil and water were separated again, the oil phase was washed with water until neutral, and the solid was collected by methanol precipitation. Product molecular weight is detected by GPC.

[0077] The solid obtained above was granulated and injected into corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com