Polymeric flame retardant containing silicon, phosphorus and nitrogen elements and flame retardant polylactic acid material therefrom

A technology of polymer flame retardant and polylactic acid material, which is applied in the field of polymer flame retardant and its flame retardant polylactic acid material, can solve the problem of increasing the maximum heat release rate of polylactic acid material and easy migration of low molecular weight flame retardant. , the limiting oxygen index is not significantly improved and other problems, to achieve excellent flame retardant effect, low toxicity, reduce the effect of reducing the reduction of flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

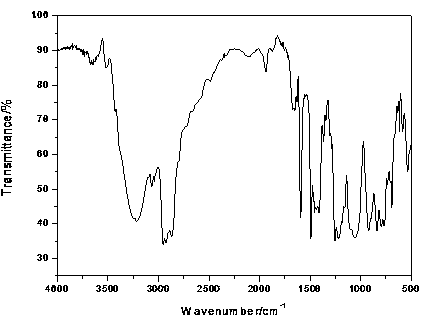

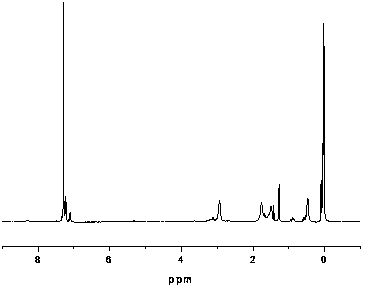

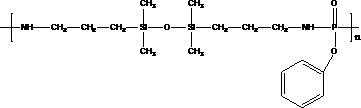

[0025] Example 1: Weigh 1.55g of 1,3-bis(3-aminopropyl)tetramethyldisiloxane and 1.01198g of triethylamine, and add 1,3-bis(3-aminopropyl)tetramethyl Disiloxane and triethylamine were dissolved in 10ml of chloroform treated with desiccant; the chloroform solution of 1,3-bis(3-aminopropyl)tetramethyldisiloxane and triethylamine was transferred into the reactor, Pass nitrogen protection, pass condensed water, stir at medium speed, and heat to reflux temperature. Weigh 1.0549g of phenyl dichlorophosphate and dissolve it in 2.5ml of dry chloroform, add the chloroform solution of phenyl dichlorophosphate dropwise to the reactor, and keep the reaction at reflux temperature for 8 hours after the addition is complete; after the reaction is complete, rotary evaporation The chloroform was removed, the residue was washed with water, then dissolved in ethanol, filtered, the filtrate was collected for rotary evaporation to remove the ethanol, the residue was dissolved in chloroform, washed ...

Embodiment 2

[0030] Example 2: Weigh 9.5 grams of polylactic acid pellets and dissolve them in 50ml of chloroform. Weigh 0.5 grams of polymer flame retardant containing silicon, phosphorus and nitrogen and dissolve them in 10ml of chloroform. After the polylactic acid is completely dissolved , Add it to the polylactic acid solution and stir, after it is completely mixed and there is no bubbles, coat the film on the glass plate and place it at room temperature to volatilize the chloroform to prepare the polymer flame retardant containing silicon, phosphorus and nitrogen of the present invention Flame retardant polylactic acid. Its limiting oxygen index value is 22.5%.

Embodiment 3

[0031] Example 3: Weigh 9 grams of polylactic acid pellets and dissolve them in 50ml of chloroform. Weigh 1 gram of polymer flame retardant containing silicon, phosphorus and nitrogen and dissolve them in 10ml of chloroform. After the polylactic acid is completely dissolved , Add it to the polylactic acid solution and stir, after it is completely mixed and there is no bubbles, coat the film on the glass plate, and volatilize the chloroform at room temperature to obtain the silicon, phosphorus, and nitrogen-containing polymer flame retardant of the present invention. Burning polylactic acid. Its limiting oxygen index value is 23.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com