Electric pulse-assisted nitriding method of austenitic stainless steel

An austenitic stainless steel, electric pulse technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of pollution, narrowing of application scope, difficult to treat waste water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

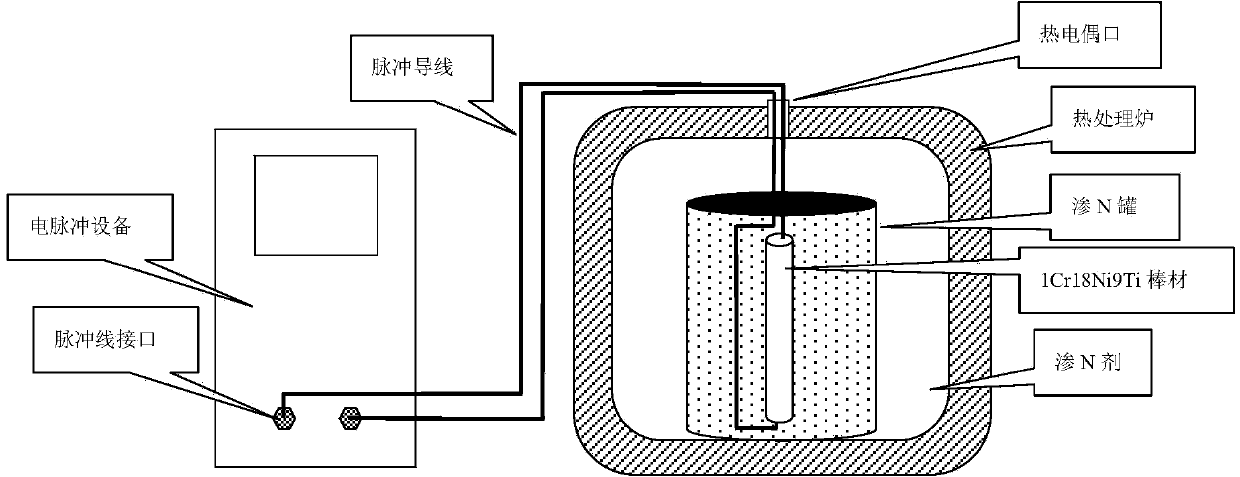

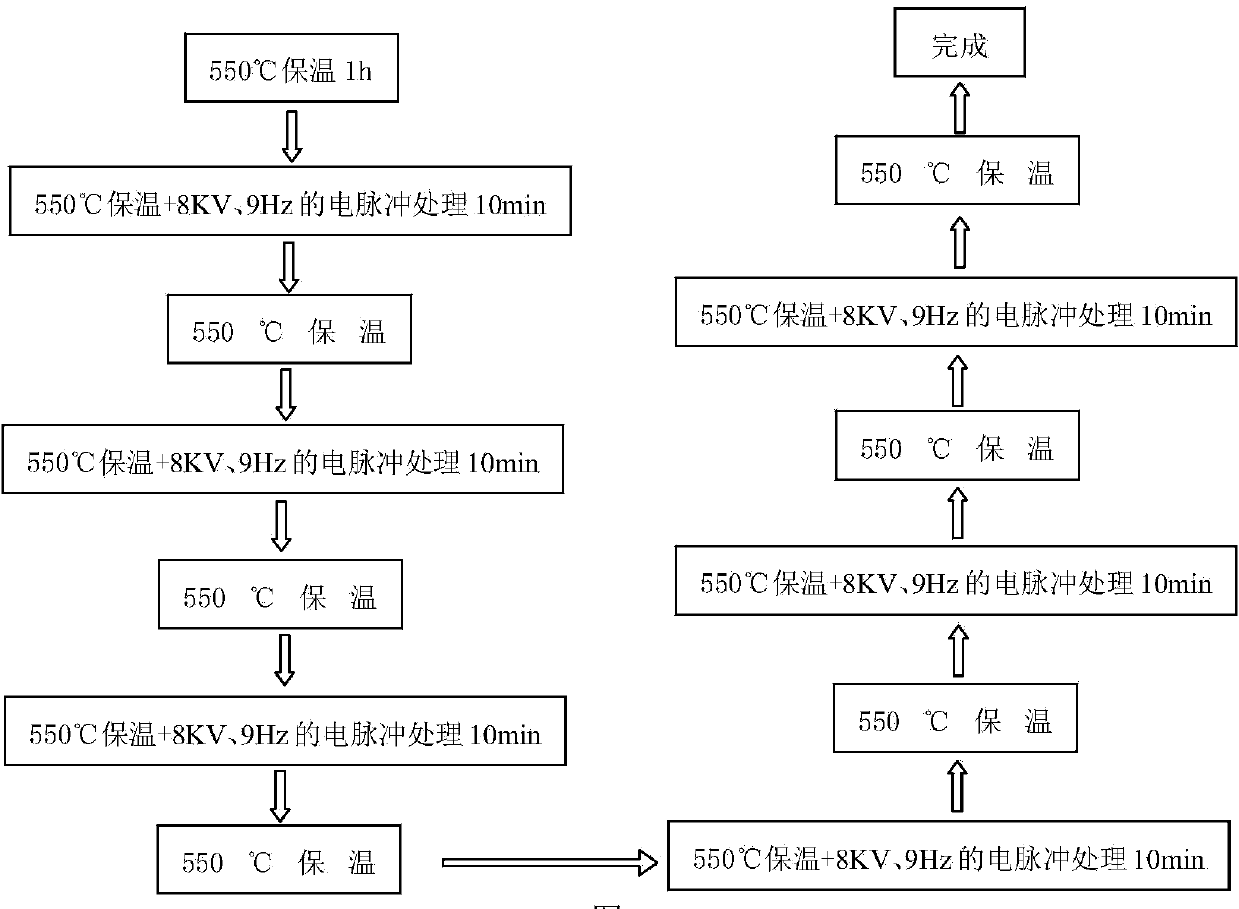

[0020] The nitriding method of austenitic stainless steel will be described in detail below. This embodiment takes 1Cr18Ni9Ti as an example for demonstration, and this exemplary embodiment does not limit the scope of protection of the claims.

[0021] First, the 1Cr18Ni9Ti workpiece that needs to be infiltrated with N is treated, and the surface of the workpiece is sandblasted or pickled to remove the passivation film on the surface of 1Cr18Ni9Ti that hinders the diffusion of N.

[0022] Configure nitrogenizing agent, which is a mixture of wood chips, urea, sodium carbonate and ammonium chloride, and mix evenly according to the mass ratio of 10:6:3:1. After calculation and many experiments, the nitriding agent according to this mass ratio can achieve the best required technical effect. Among them, urea is the source of the main active N element, sawdust can improve the activity of the penetrating agent, ammonium chloride is heated and decomposed to produce HCl gas, which can c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com