Ultrathin carbon film prepared with ECR (Electron Cyclotron Resonance) oxygen-argon plasma etching technology and method of preparing ultrathin carbon film

A technology of plasma and argon ions, applied in the field of ultra-thin carbon film, can solve the problems of reducing the surface roughness and performance of carbon film, and achieve the effect of superior scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

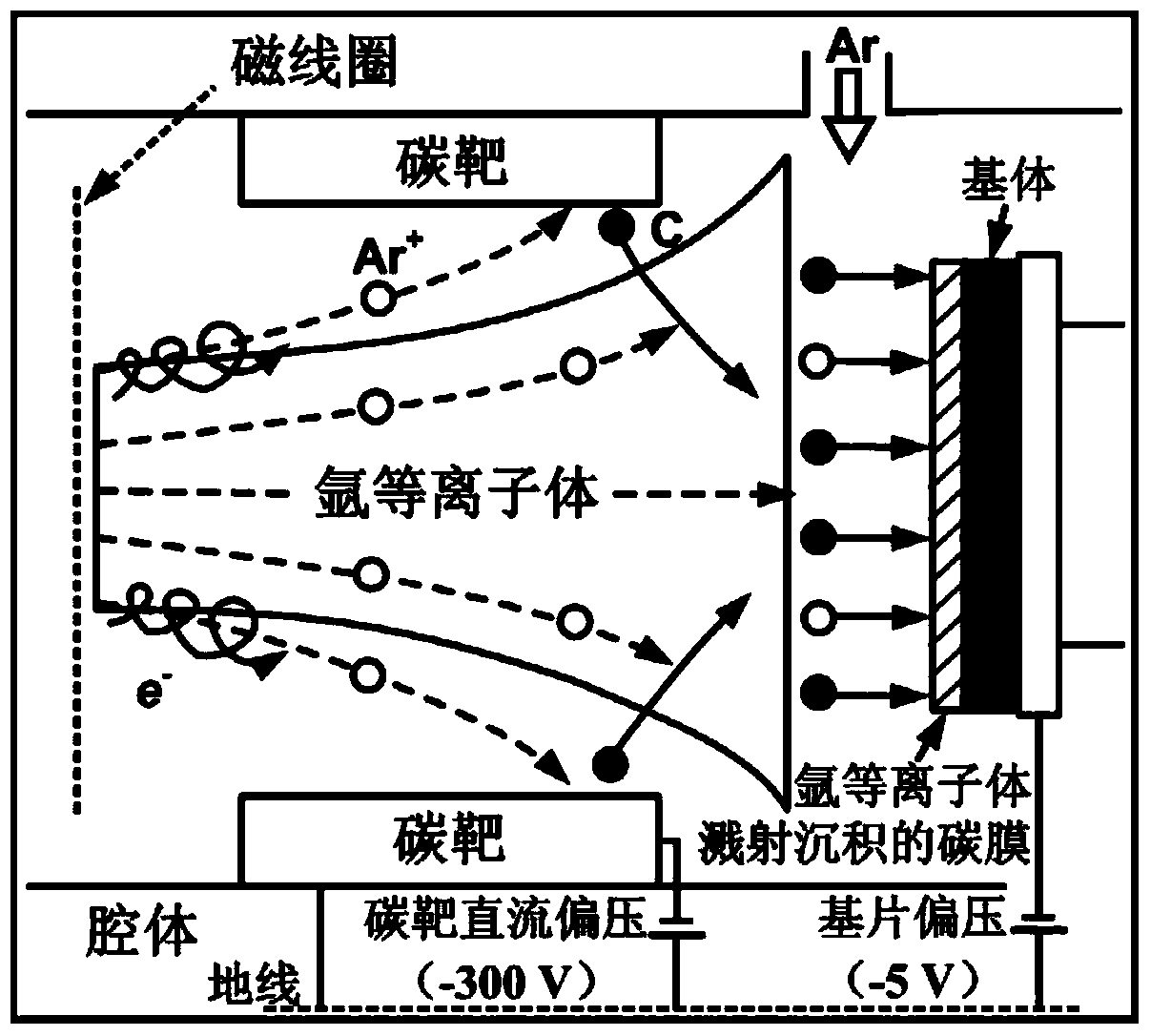

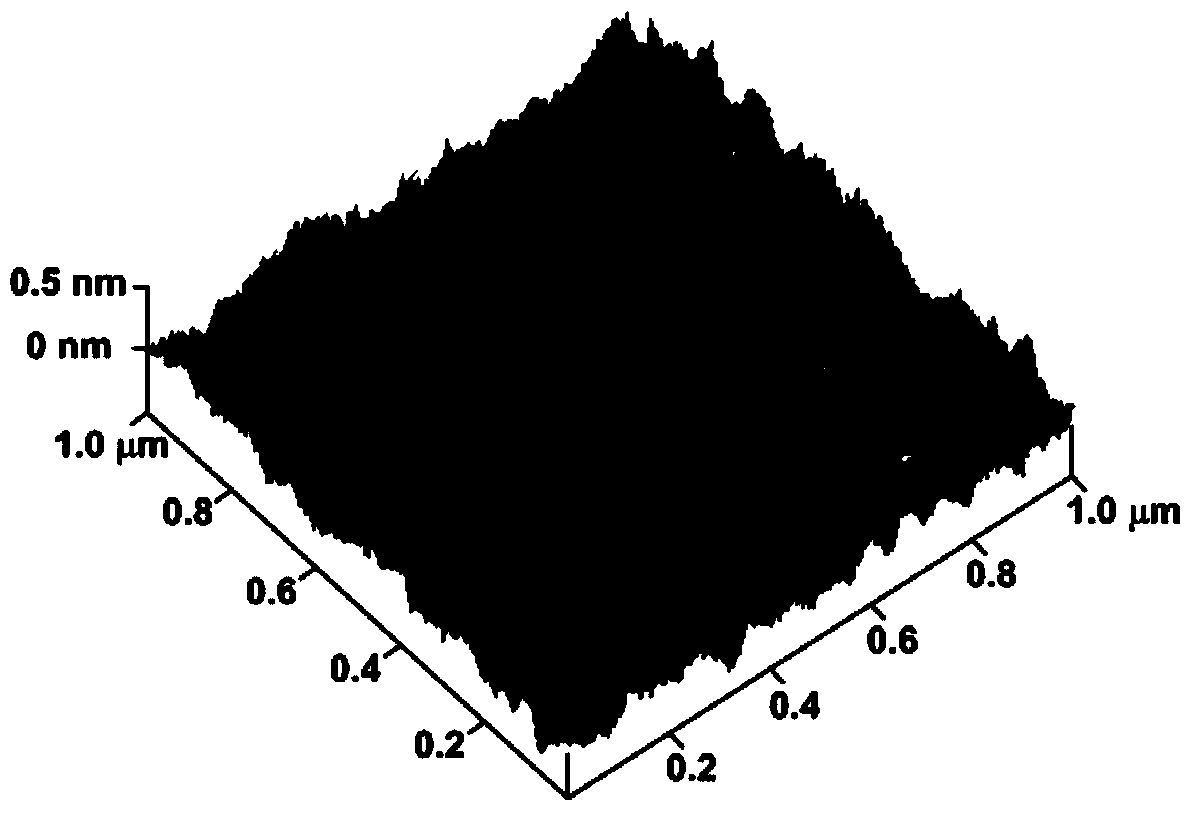

[0030] 1) see figure 1 , with the hard disk not coated with carbon film as the substrate, put it into the plasma chamber after ultrasonic cleaning, when the vacuum degree in the chamber is pumped to 3×10 -4 After Pa, argon gas was introduced to raise the pressure in the vacuum chamber to 4×10 -2 Pa. Apply a magnetic coil current of 420A, turn on the microwave source, and adjust the microwave power to 200W. Under the coupling action of the magnetic field and microwave, the initial electrons in the cavity will generate electron cyclotron motion to ionize the incoming argon gas to obtain a high ionization rate. , High-density argon plasma. After the plasma state is stable, a DC bias of -300V is applied to the carbon target, and the argon ions in the plasma accelerate the bombardment of the carbon target. Under the action of the substrate bias of -5V, the carbon in the carbon target is deposited on the surface of the substrate to form carbon film. The sputtering deposition tim...

Embodiment 2

[0035] 1) With silicon as the substrate, put it into the plasma cavity after ultrasonic cleaning, when the vacuum in the cavity reaches 2×10 -4 After Pa, argon gas was introduced to increase the pressure in the vacuum chamber to 3×10 -2 Pa. Apply a magnetic coil current of 350A, turn on the microwave source, and adjust the microwave power to 100W. Under the coupling action of the magnetic field and microwave, the initial electrons in the cavity will generate electron cyclotron motion to ionize the incoming argon gas to obtain a high ionization rate. , High-density argon plasma. After the plasma state is stable, a DC bias of -200V is applied to the carbon target, and the argon ions in the plasma accelerate the bombardment of the carbon target. Under the action of the substrate bias of -30V, the carbon in the carbon target is deposited on the surface of the substrate to form carbon film. The sputtering deposition time is 1 min, and according to the deposition rate of 3 nm / min...

Embodiment 3

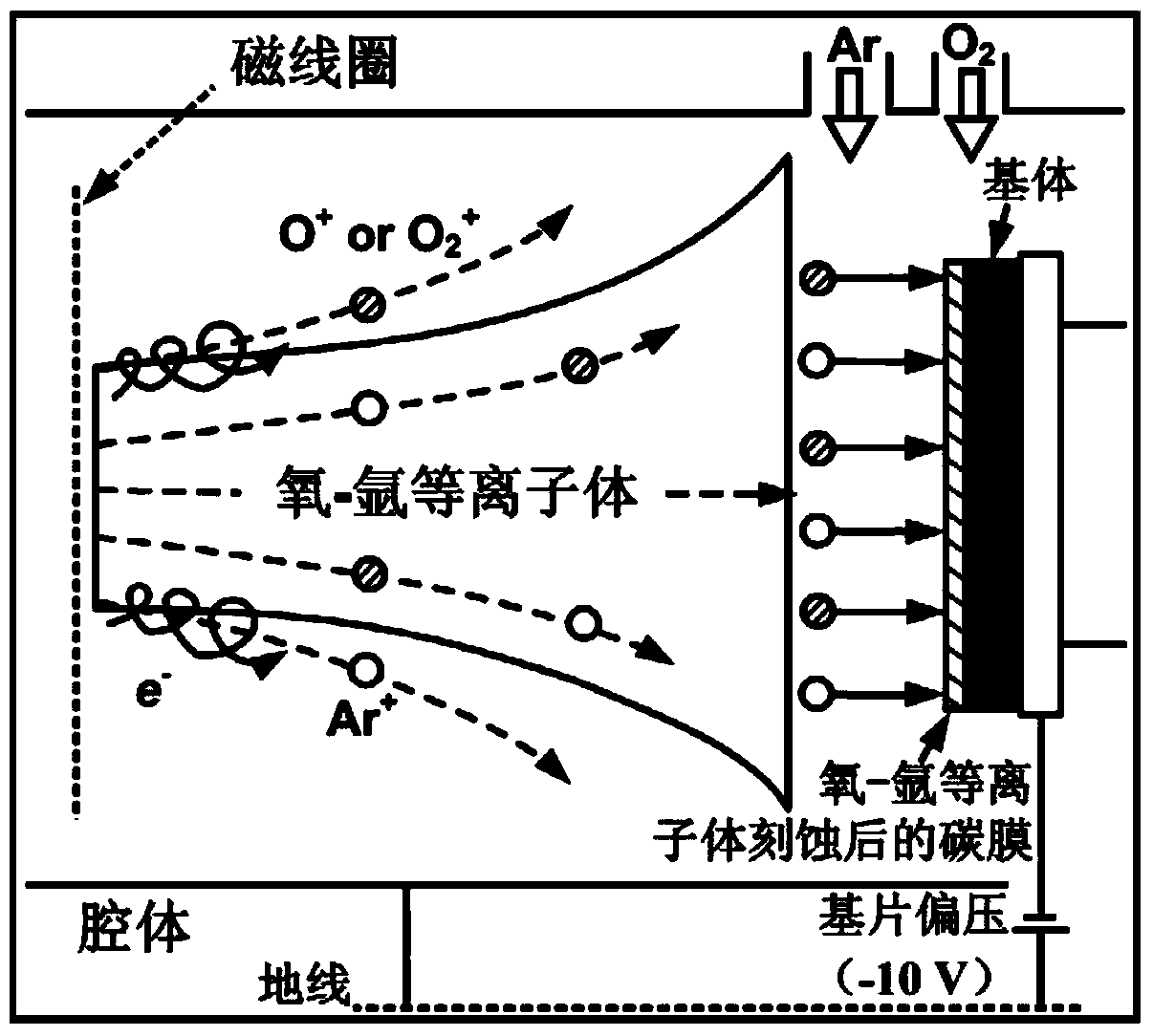

[0038] 1) Take the hard disk without carbon film as the substrate, put it into the plasma chamber after ultrasonic cleaning, and when the vacuum in the chamber is pumped to 4×10 -4 After Pa, argon gas was introduced to increase the pressure in the vacuum chamber to 5.5×10 -2 Pa. Apply a magnetic coil current of 380A, turn on the microwave source, and adjust the microwave power to 300W. Under the coupling action of the magnetic field and microwave, the initial electrons in the cavity will generate electron cyclotron motion to ionize the incoming argon gas to obtain a high ionization rate. , High-density argon plasma. After the plasma state is stable, a DC bias of -280V is applied to the carbon target, and the argon ions in the plasma accelerate the bombardment of the carbon target. Under the action of the substrate bias of -10V, the carbon in the carbon target is deposited on the surface of the substrate to form carbon film. The sputtering deposition time is 2 min, and accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Root mean square roughness | aaaaa | aaaaa |

| Root mean square roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com