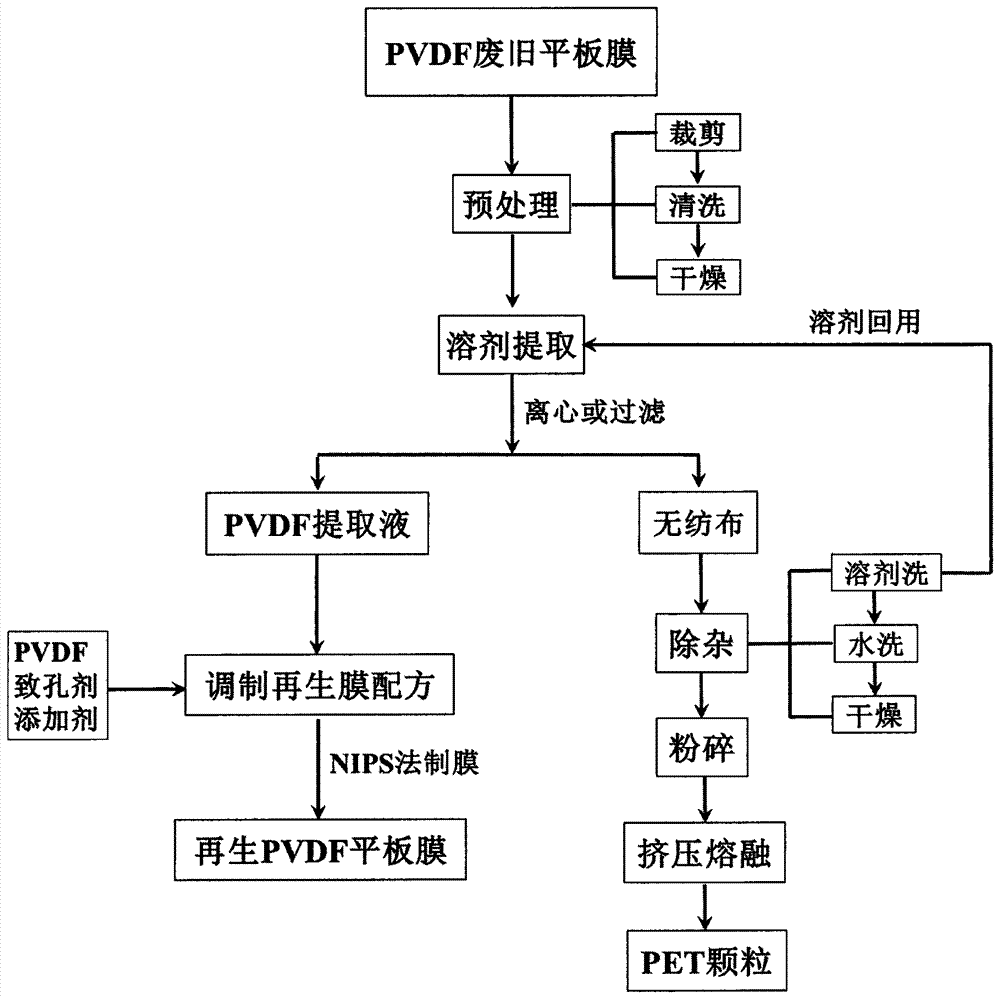

Recycling method of waste polyvinylidene fluoride (PVDF) flat sheet membrane

A polyvinylidene fluoride, flat film technology, applied in recycling technology, plastic recycling, chemical instruments and methods, etc., can solve the problems that do not involve the separation method of membrane material and support layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Cut the waste PVDF flat membrane into a 17cm×20cm membrane, first soak and clean it with a NaClO solution with a concentration of 10000ppm for 5 hours, then soak and clean it with a concentration of 5% HCl for 5 hours, and finally rinse it with clean water until it is neutral, and then dry it at 60 °C for drying. Submerge the dried waste film in DMAC, the amount of extraction solvent is 0.5L per square meter of waste film, soak and dissolve at 20°C for 10 hours, dissolve the PVDF on the surface of the film, and then use the centrifugation method to solidify the extract with the non-woven fabric. liquid separation. Centrifuge at 10,000rpm for 20min to remove impurity particles such as non-woven fibers, then add 50g of fresh PVDF powder and 50g of PVP to each liter of PVDF extract, and stir to dissolve. After standing for 48 hours for defoaming, the membrane was formed by the NIPS method. Immerse the diaphragm in deionized water, the water temperature is 25°C, and the i...

example 2

[0019] Cut the waste PVDF flat membrane into a 15cm×20cm membrane, first soak and clean it with a NaClO solution with a concentration of 4000ppm for 12 hours, then soak and clean it with a concentration of 3% HCl for 3 hours, and finally rinse it with clean water until it is neutral, and dry it at 60 °C for drying. The dried waste membrane was immersed in NMP, soaked and dissolved at 40°C for 10 hours to dissolve the PVDF on the surface of the membrane, and then the extract was separated from the non-woven fabric by filtration. Remove impurity particles such as non-woven fabric fibers by filtration with a 220 μm filter membrane. Subsequently, 25 g of fresh PVDF powder and 80 g of PEG were added to every liter of PVDF extract, and stirred to dissolve. After standing for 48 hours for defoaming, the membrane was formed by the NIPS method. Immerse the diaphragm in deionized water, the water temperature is 25°C, and the immersion time is 20min. The performance of the PVDF regene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com