Method for producing secondary element mineral fertilizer by activating wollastonite

A technology of mineral fertilizer and wollastonite, which is applied in the field of agricultural science, wollastonite activation and production of medium-element mineral fertilizer, can solve the problems of lack of various trace elements and lack of effective supplement of mineral nutrients, etc. To achieve the effect of reducing energy consumption, convenient material acquisition, and complete composition of medium elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

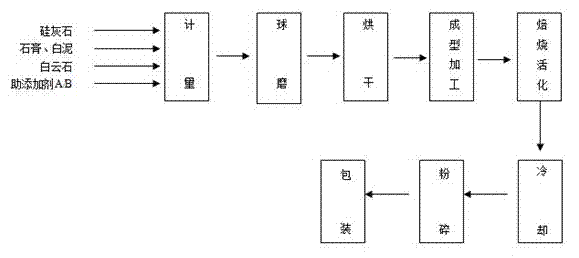

[0014] A fertilizer company is a large state-owned enterprise that produces nitrogen, phosphorus and potassium compound fertilizers. Using this process to produce medium-weight element fertilizers and adding them to nitrogen, phosphorus, and potassium compound fertilizers as additives can make the original compound fertilizers more comprehensive in composition, more balanced in nutrition, and reduce production costs by nearly 55%. Its main process is as figure 1 shown. The mineral raw materials (according to mass percentage) are compatible as follows: 50% wollastonite, 12% gypsum, 25% white mud, 12% dolomite, 1% of auxiliary additives A and B, of which auxiliary additive A is potassium Feldspar + muscovite (mass ratio 1:1); auxiliary additive B is thenardite + salt (mass ratio 1:1), and the weight ratio between auxiliary additives A and B is also 1:1. The process flow is: fully mix the above mineral raw materials, and ball mill until the particle size is less than 0.074mm; ...

Embodiment 2

[0016] A fertilizer company in Shanxi adopts this process to produce medium-weight element fertilizers. The material (according to mass percentage) compatibility is: wollastonite 37%, gypsum 25%, white mud 26%, dolomite 10%, additives A and B are 2 %, wherein auxiliary additive A is illite + potassium carbonate (mass ratio 1:1); auxiliary additive B is salt + sodium fluoride (mass ratio 1:1), and the weight ratio between auxiliary additives A and B is 1 :2. The process flow is as follows: fully mix the above mineral raw materials, and perform ball milling until the particle size is less than 0.090mm; then dry the mixed material until the moisture content is less than 6%; shape the dried mixed material into a particle size About 1.5cm pellets, and enter the activation kiln for roasting, the temperature is controlled at 950 ° C, and the roasting time is 1.5 hours. The activated pellets are cooled and crushed to make mineral compound fertilizers. Among them, through the third-p...

Embodiment 3

[0018] A fertilizer company in Guangdong is a large private enterprise that produces soil conditioners. Using this process to produce medium elements, the production cost has dropped by nearly 51%. The mineral raw materials used (in terms of mass percentage) are compatible with: 60% wollastonite, 10% gypsum, 20% white mud, and 9% dolomite. , auxiliary additives A and B are 1%, of which auxiliary additive A is illite + muscovite (mass ratio 1:1); auxiliary additive B is Glauber’s salt + sodium fluoride (mass ratio 1:1), auxiliary additives A and B The weight ratio between them is also 1:0.75. The process flow is: fully mix the above mineral raw materials, and ball mill until the particle size is less than 0.074mm; then dry the mixed material until the moisture content is less than 5%; shape the dried mixed material into a particle size of about 2cm The pellets are put into the activation kiln for calcination, the temperature is controlled at 1050°C, and the calcination time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com