Biogas slurry compound insecticide for preventing and treating aphid

A technology of pesticides and biogas slurry, applied in pesticides, biocides, animal repellants, etc., can solve problems such as harmful pesticide residues, human health hazards, air, water, soil pollution, etc., and reduce pesticides. Use dosage, promote crop growth, and kill good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

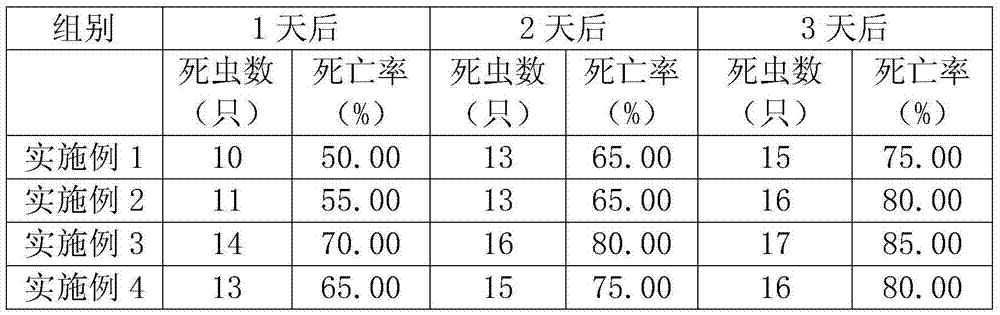

Examples

Embodiment 1

[0025] 1) Filter the fermented liquid of poultry and livestock feces that has been fermented normally for more than three months. 2 o 5 ) Potassium (K 2 O) The weight ratio is 0.1:0.05:0.1.

[0026] 2) Preparation of insecticidal composition: Mix sulfoxaflor and butylene fipronil at a weight ratio of 1:1, take 50g of the mixture, 10ml of solvent (including emulsifier), 10ml of auxiliary agent, add water to set When the volume is up to 1000ml, it is an emulsion.

[0027] 3) 99.5 kg of biogas slurry and 0.5 kg of emulsion of the insecticidal composition were mixed and prepared to obtain a biogas slurry composite insecticide for preventing and controlling aphids.

Embodiment 2

[0029] 1) Preparation of biogas slurry: filter the fermented liquid of poultry manure that has been fermented normally for more than three months, remove particulate impurities, and adjust the pH value to 8.0, of which ammonia nitrogen accounts for 79% of the total nitrogen content, and nitrogen (N) phosphorus (P 2 o 5 ) Potassium (K 2 o) The weight ratio is 0.3:0.2:0.3.

[0030] 2) Preparation of insecticidal composition: Mix sulfoxaflor and butylene fipronil at a weight ratio of 1:8, take 900g of the mixture, 450ml of solvent (including emulsifier), 200ml of additives, add water to set When the volume is up to 1000ml, it is an emulsion.

[0031] 3) 99.8 kg of biogas slurry and 0.2 kg of emulsion of the insecticidal composition were mixed and prepared to obtain a biogas slurry composite insecticide for preventing and controlling aphids.

Embodiment 3

[0033] 1) Preparation of biogas slurry: filter the fermented liquid of poultry manure that has been fermented normally for more than three months, remove particulate impurities, and adjust the pH value to 7.8, in which ammoniacal nitrogen accounts for 76% of the total nitrogen content, and nitrogen (N) phosphorus (P 2 o 5 ) Potassium (K 2 o) The weight ratio is 0.2:0.15:0.1.

[0034] 2) Preparation of insecticidal composition: mix sulfoxaflor and butylene-fipronil at a weight ratio of 1:4, take 50kg of the mixture, 35kg of adsorbent or filler, and 15kg of adjuvant, and mix well to obtain a powder .

[0035] 3) Mix 99.6 kg of biogas slurry and 0.4 kg of powder of the insecticidal composition to prepare biogas slurry composite insecticide for preventing and controlling aphids.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com