Low-density propping agent taking flint clay as raw material and preparation method thereof

A low-density, proppant technology, applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of unfavorable particle size, increased energy consumption, and many hollow particles, and achieves a reduction in powder particle size. diameter, improve drying efficiency, and purify the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

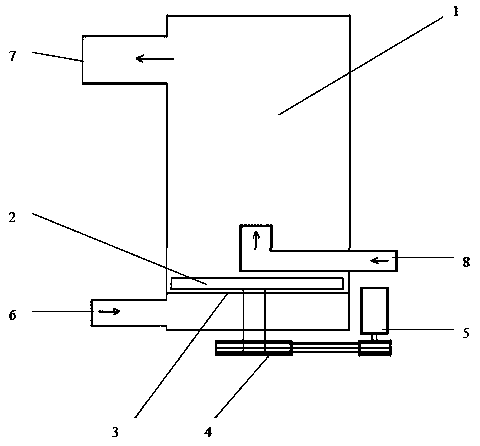

Method used

Image

Examples

Embodiment 1

[0027] (1) Main ingredients (weight ratio): 54% raw burnt gemstones, 8% lightly burnt gemstones, and 38% easy-grinding sandstone;

[0028] Among them, the chemical composition (weight ratio) of the coke gem raw material: Al 2 o 3 38.5%, SiO 2 44.5%, Fe 2 o 3 0.89%, K 2 O 0.1%, Na 2 O 0.12%, CaO 0.12%, MgO 0.18%, TiO 2 0.6%; loss on ignition 14.2%;

[0029] Composition of underburned gemstones (weight ratio): calcined from burnt gemstone raw material; calcining temperature 1200~1450°C, calcination time 0.5~1 hour; its chemical composition is: Al 2 o3 46.52%, SiO 2 48.9%, Fe 2 o 3 1.1%, K 2 O 0.15%, Na 2 O 0.17, CaO 0.31%, MgO 0.31%, TiO 2 0.75%; loss on ignition 0.5%;

[0030] Easy to grind sandstone (weight ratio): fine powder after sandstone ore grinding, containing SiO 2 95%.

[0031] Flux (weight ratio): limestone 2%.

[0032] The main material is mixed with a flux to form a compound.

[0033] (2) Mixing material: alumina ball Grinding medium: wat...

Embodiment 2

[0037] (1) Main ingredients (weight ratio): 52% raw burnt gemstone, 14% lightly burnt gemstone, and 34% easy-grinding sandstone. The composition of each raw material is the same as that in Example 1.

[0038] Flux (weight ratio): basic magnesium carbonate 0.5%.

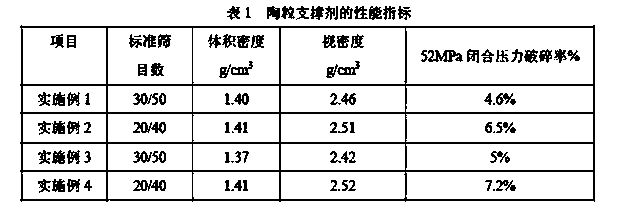

[0039] (2) The preparation method is the same as in Example 1. The performance index of the product obtained is shown in Table 1.

Embodiment 3

[0041] (1) Main ingredients (weight ratio): 53% raw burnt gemstone, 2% lightly burnt gemstone, and 45% easy-grinding sandstone. The composition of each raw material is the same as that in Example 1.

[0042] Flux (by weight): Dolomite 1.5%.

[0043] (2) The preparation method is the same as in Example 1. The performance index of the product obtained is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com