Method for improving quality of low-temperature tar during coal pyrolysis

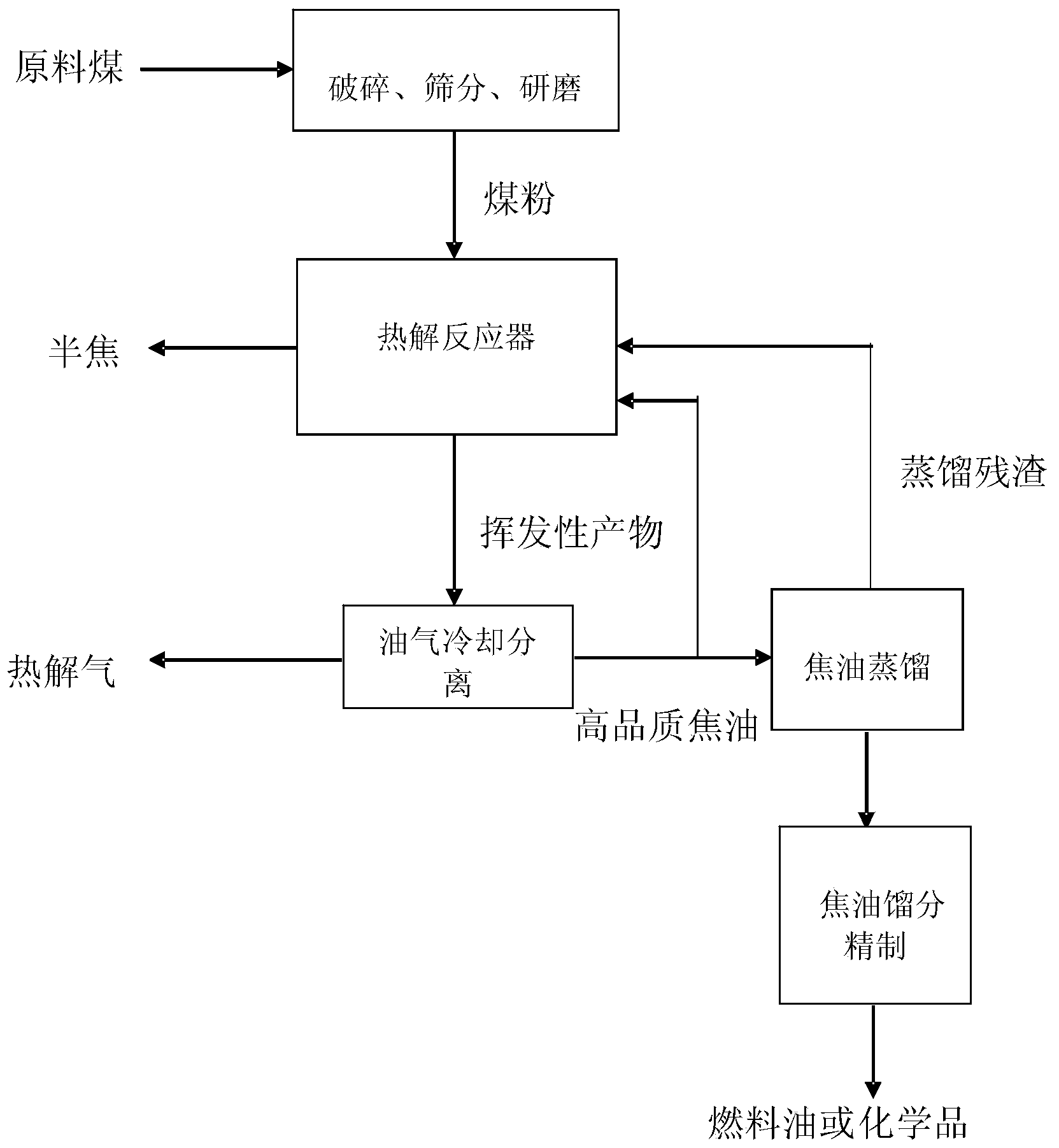

A technology for low-temperature tar and low-temperature coal tar, which is applied in the field of coal pyrolysis, can solve problems such as poor quality and low tar yield, and achieve the effects of convenient operation, improved yield and quality, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Raw coal is peat.

[0033] After crushing, sieving and grinding, the pulverized coal and low-temperature coal tar that meet the particle size requirements of 10-1000 μm are mixed according to the mass ratio of 100:1, and then placed on the fixed bed of the pyrolysis reactor for pyrolysis reaction. The reaction temperature is 600 ° C. The residence time is 30min. Centrifugal dehydration can be used for tar dehydration.

[0034] The yield of tar was 1.79% higher than the theoretically calculated value of pyrolysis of the two raw materials alone, and the yield of n-hexane solubles was 2.98% higher than the calculated value.

Embodiment 2

[0036] The raw coal is lignite.

[0037] After crushing, sieving, and grinding, the pulverized coal and low-temperature coal tar that meet the particle size requirements of 10-1000 μm are mixed according to the mass ratio of 100:3, and placed on the fluidized bed of the pyrolysis reactor for pyrolysis reaction. The reaction temperature is 600 ℃, the residence time is 30min. Centrifugal dehydration can be used for tar dehydration.

[0038] The yield of tar is 1.36% higher than the theoretically calculated value of pyrolysis of the two raw materials alone, and the yield of n-hexane solubles is 3.53% higher than the calculated value.

Embodiment 3

[0040] Raw coal is bituminous coal.

[0041] After crushing, sieving, and grinding, the pulverized coal and low-temperature coal tar that meet the particle size requirements of 10-1000 μm are mixed according to the mass ratio of 100:5, and then placed in a pyrolysis reactor for pyrolysis reaction. The reaction temperature is 600 ° C. The time is 30 minutes. Centrifugal dehydration can be used for tar dehydration.

[0042] The yield of tar was 0.91% higher than the theoretically calculated value of pyrolysis of the two raw materials alone, and the yield of n-hexane solubles was 3.64% higher than the calculated value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com