Dry powder extinguisher containing modified smectite powder

A technology of dry powder fire extinguishing agent and montmorillonite powder, which is applied in the direction of fire prevention equipment, can solve the problems of poor cooling performance and recombustion resistance, limited fire extinguishing effect, poor fire extinguishing effect, etc., and achieves strong moisture resistance, high fire extinguishing efficiency, and fire resistance Good reflammability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

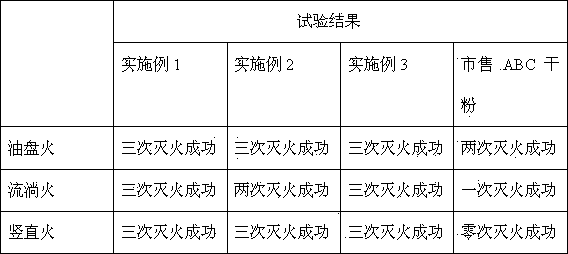

Examples

Embodiment 1

[0018] A dry powder fire extinguishing agent containing modified montmorillonite powder, made of the following raw materials in parts by weight: 80 parts of modified montmorillonite powder, 7 parts of mica powder, 13 parts of hydrated zinc sulfide, 5 parts of calcium hydroxide, stearic acid 6 parts of magnesium, 5 parts of nitrogen-containing silicon oil, 2 parts of expandable graphite, 3 parts of magnesite, 3 parts of urea, 6 parts of calcium lignosulfonate, 4 parts of bamboo charcoal fiber, 2 parts of industrial essence, 3 parts of zinc borate, chlorine 2 parts of paraffin, 8 parts of diatomaceous earth.

[0019] Wherein, the modified montmorillonite powder is prepared by the following method: calcining the montmorillonite at a temperature of 700° C. for 3 hours, soaking it in 12% hydrochloric acid solution for 3 hours, washing it with deionized water to neutrality, and drying it. Then add charcoal powder equivalent to 2% of the powder weight, 4% cetyltrimethylammonium bromi...

Embodiment 2

[0022] A dry powder fire extinguishing agent containing modified montmorillonite powder, 70 parts of modified montmorillonite powder, 6 parts of mica powder, 10 parts of zinc sulfide hydrate, 3 parts of calcium hydroxide, 7 parts of magnesium stearate, and 3 parts of nitrogen-containing silicone oil , 2 parts of expandable graphite, 3 parts of magnesite, 2 parts of urea, 7 parts of calcium lignosulfonate, 3 parts of bamboo charcoal fiber, 2 parts of industrial essence, 2 parts of zinc borate, 1 part of chlorinated paraffin, diatomaceous earth 8 servings.

[0023] Wherein, the modified montmorillonite powder is prepared by the following method: calcining the montmorillonite at a temperature of 600° C. for 4 hours, soaking it in 10% hydrochloric acid solution for 4 hours, washing it with deionized water to neutrality, and drying it. Then add charcoal powder equivalent to 1% of the powder weight, 3% cetyltrimethylammonium bromide, and 4% 2-bromo-3,3,3-trifluoropropene. Stir for ...

Embodiment 3

[0026] A dry powder fire extinguishing agent containing modified montmorillonite powder, made of the following raw materials in parts by weight: 90 parts of modified montmorillonite powder, 10 parts of mica powder, 15 parts of hydrated zinc sulfide, 5 parts of calcium hydroxide, stearic acid 8 parts of magnesium, 5 parts of nitrogen-containing silicon oil, 3 parts of expandable graphite, 3 parts of magnesite, 3 parts of urea, 6 parts of calcium lignosulfonate, 5 parts of bamboo charcoal fiber, 3 parts of industrial essence, 4 parts of zinc borate, chlorine 3 parts of paraffin, 10 parts of diatomaceous earth.

[0027] Wherein, the modified montmorillonite powder is prepared by the following method: calcining the montmorillonite at a temperature of 800° C. for 3 hours, soaking it in 12% hydrochloric acid solution for 3 hours, washing it with deionized water to neutrality, and drying it. Then add charcoal powder equivalent to powder weight%, 4% cetyltrimethylammonium bromide, 4% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com