Method for preparing graphene dispersion liquid by utilizing pyrenyl benzoic acid polyether ester parent reagent

A graphene dispersion, pyrene-based benzoic acid technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements and other directions, can solve the problems of graphene structure being easily destroyed and stable, and achieve the effect of wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

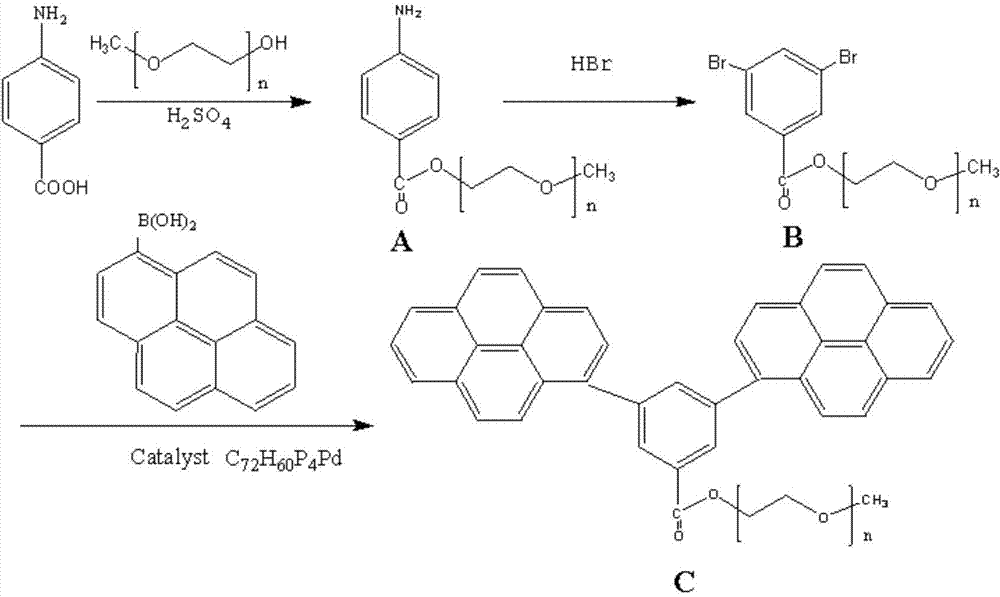

[0021] (1) Dissolve 8g of polyethylene glycol monomethyl ether (Mn=750) and 1.75g of p-aminobenzoic acid in the solvent THF, transfer the above solution to a 100mL round bottom flask, and then add 1mL of concentrated sulfuric acid to it, A precipitate formed and was heated to reflux for 30 minutes. Then transfer the reaction mixture into a 250mL beaker, add 10% sodium carbonate to pH ≈ 9, filter with suction, wash, extract twice with ether, and purify to obtain product A. 3g of A, 40ml of water, 40% 20mmolHBr and a certain amount of 30% 20mmolH 2 o 2 Mix well at room temperature, and purify to obtain product B. Dissolve 1.00 g of B and 0.25 g of 1-boronic acid pyrene in the solvent THF, add 40 ml of Na 2 CO 3 aqueous solution. Then 0.10 g of tetrakis(triphenylphosphine) palladium was added thereto, the mixture was vigorously stirred under a nitrogen atmosphere, heated to reflux for 24 hours, the mixture was layered, the aqueous phase layer was washed twice with dichloro...

Embodiment 2

[0024] (1) Dissolve 8g of polyethylene glycol monomethyl ether (Mn=1000) and 1.64g of p-aminobenzoic acid in the solvent THF, transfer the above solution to a 100mL round bottom flask, and then add 1mL of concentrated sulfuric acid to it, A precipitate formed and was heated to reflux for 30 minutes. Then transfer the reaction mixture into a 250mL beaker, add 10% sodium carbonate to pH ≈ 9, filter with suction, wash, extract twice with ether, and purify to obtain product A. 3.00g of A, 40ml of water, 40% 20mmolHBr and a certain amount of 30% 20mmolH 2 o 2 Mix well at room temperature, and purify to obtain product B. Dissolve 1.00 g of B and 0.25 g of 1-boronic acid pyrene in the solvent THF, add 40 ml of Na 2 CO 3aqueous solution. Then 0.10 g of tetrakis(triphenylphosphine) palladium was added thereto, the mixture was vigorously stirred under a nitrogen atmosphere, heated to reflux for 24 hours, the mixture was layered, the aqueous phase layer was washed twice with dichlor...

Embodiment 3

[0027] (1) Dissolve 8g of polyethylene glycol monomethyl ether (Mn=550) and 2.19g of p-aminobenzoic acid in the solvent THF, transfer the above solution to a 100mL round bottom flask, and then add 1mL of concentrated sulfuric acid to it, A precipitate formed and was heated to reflux for 30 minutes. Then transfer the reaction mixture into a 250mL beaker, add 10% sodium carbonate to pH ≈ 9, filter with suction, wash, extract twice with ether, and purify to obtain product A. 3.00g of A, 40ml of water, 40% 20mmolHBr and 30% 24mmolH 2 o 2 Mix well at room temperature, and purify to obtain product B. Dissolve 1.00 g of B and 0.93 g of 1-boronic acid pyrene in the solvent THF, add 40 ml of Na 2 CO 3 aqueous solution. Then 0.10 g of tetrakis(triphenylphosphine) palladium was added thereto, the mixture was vigorously stirred under a nitrogen atmosphere, heated to reflux for 24 hours, the mixture was layered, the aqueous phase layer was washed twice with dichloromethane, and purifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com