Preparation method of twinborn spheroidal calcium tungstate microcrystallines

A calcium tungstate, spherical technology, applied in the field of micro-nano material preparation, can solve the problems of harsh high-temperature reaction conditions, complex preparation process, difficult size control, etc., and achieve the effects of environmental protection and easy availability of raw materials, good dispersibility, and uniform size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

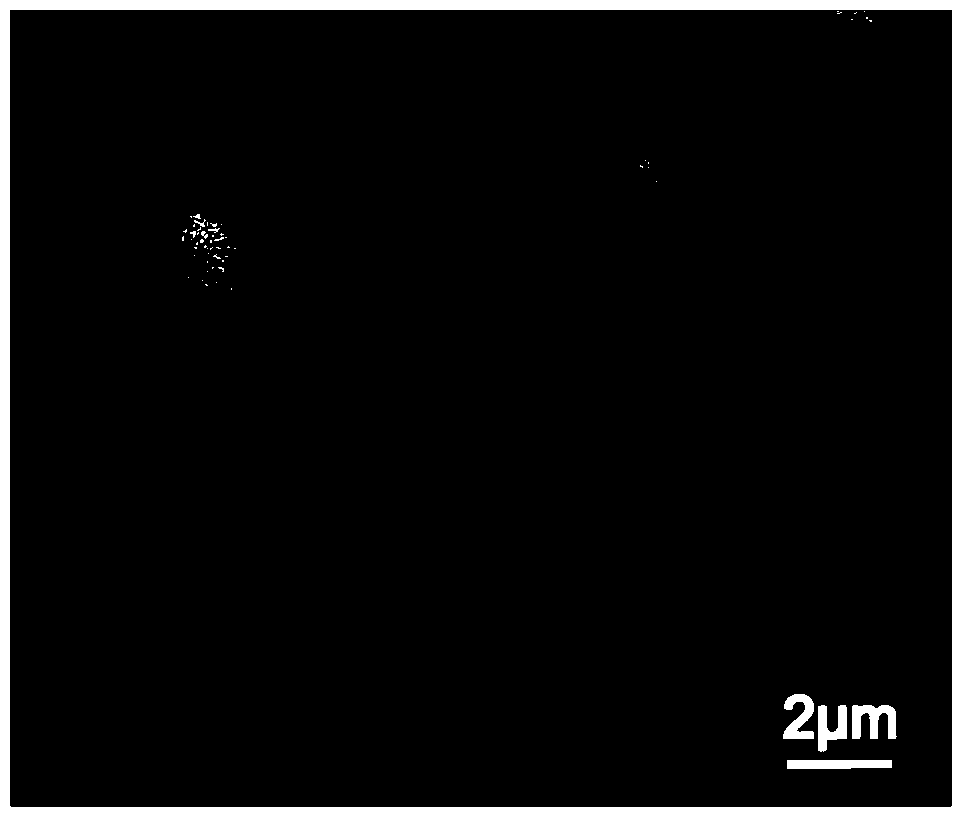

[0025] The SEM image of the calcium tungstate twin spheres prepared in this example is as follows figure 1 shown , The preparation method comprises the following steps:

[0026] 1) Weigh 0.076g cyclodextrin and dissolve it in 10ml deionized water, stir well, add 0.3299g sodium tungstate to make solution A; weigh 0.2361g calcium nitrate and dissolve it in 10ml deionized water to make solution B;

[0027] 2) Under stirring, add 10ml of solution B into 10ml of solution A, and stir for 1 hour at room temperature to prepare calcium tungstate twin balls;

[0028] 3) After the reaction, the reaction solution was centrifuged, and then the precipitate was washed several times with deionized water and absolute ethanol;

[0029] 4) Dry the precipitate in a vacuum drying oven at 50°C to finally obtain white calcium tungstate powder.

Embodiment 2

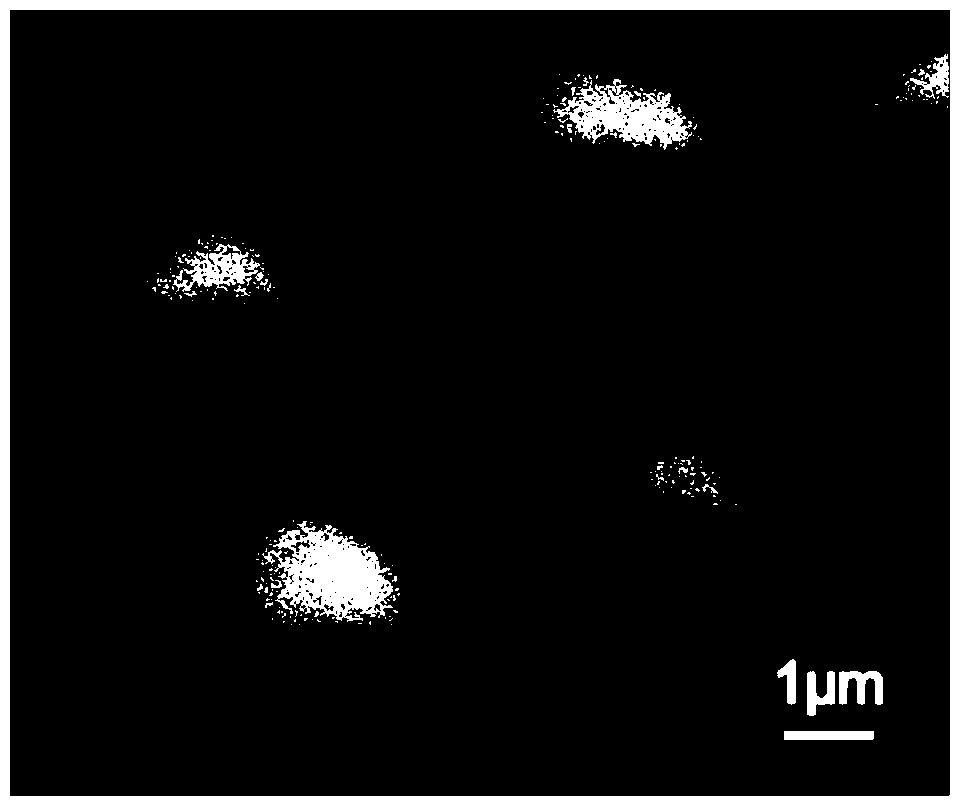

[0031] The SEM image of the calcium tungstate twin spheres prepared in this example is as follows figure 2 shown , The preparation method comprises the following steps:

[0032] 1) Weigh 0.076g cyclodextrin and dissolve it in 10ml deionized water, stir well, add 0.3299g sodium tungstate to make solution A; weigh 0.2361g calcium nitrate and dissolve it in 10ml deionized water to make solution B;

[0033] 2) Under stirring, add 10ml of solution B into 10ml of solution A, stir and react for 3 hours at room temperature to obtain calcium tungstate twin balls;

[0034] 3) After the reaction, the reaction solution was centrifuged, and then the precipitate was washed several times with deionized water and absolute ethanol;

[0035] 4) Dry the precipitate in a vacuum drying oven at 50°C to finally obtain white calcium tungstate powder.

Embodiment 3

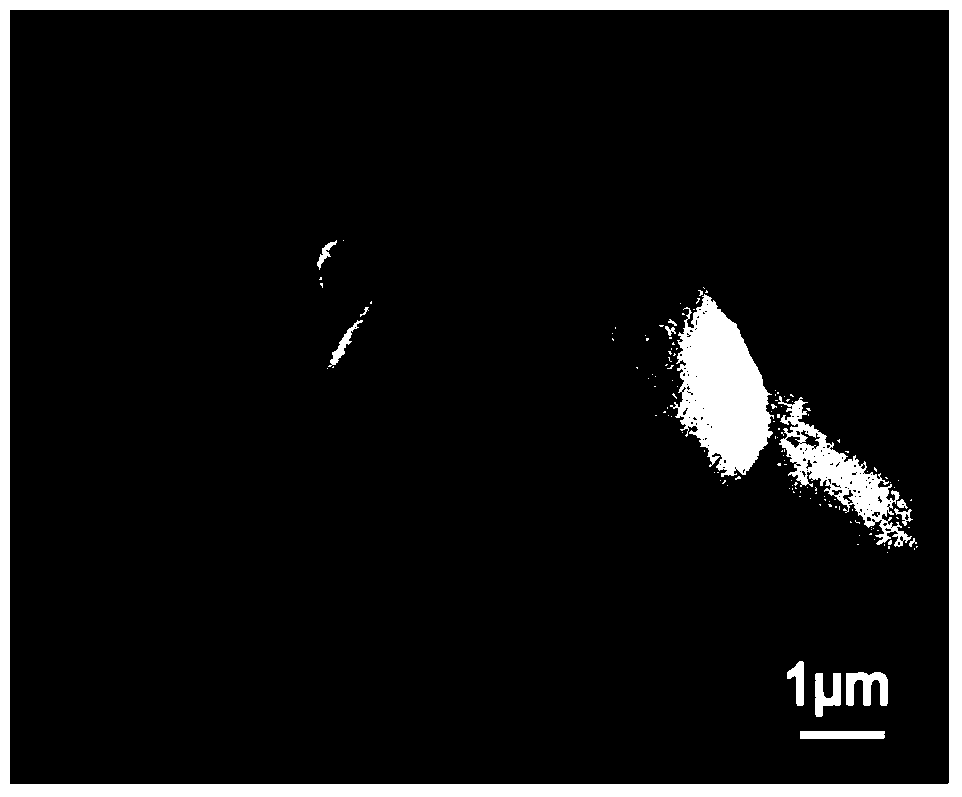

[0037] The SEM image of the calcium tungstate twin spheres prepared in this example is as follows image 3 shown , The preparation method comprises the following steps:

[0038] 1) Weigh 0.076g cyclodextrin and dissolve it in 10ml deionized water, stir well, add 0.3299g sodium tungstate to make solution A; weigh 0.2361g calcium nitrate and dissolve it in 10ml deionized water to make solution B;

[0039] 2) Under stirring, add 10ml of solution B into 10ml of solution A, stir and react for 6 hours at room temperature, and obtain calcium tungstate twin balls;

[0040] 3) After the reaction, the reaction solution was centrifuged, and then the precipitate was washed several times with deionized water and absolute ethanol;

[0041] 4) Dry the precipitate in a vacuum drying oven at 50°C to finally obtain white calcium tungstate powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com