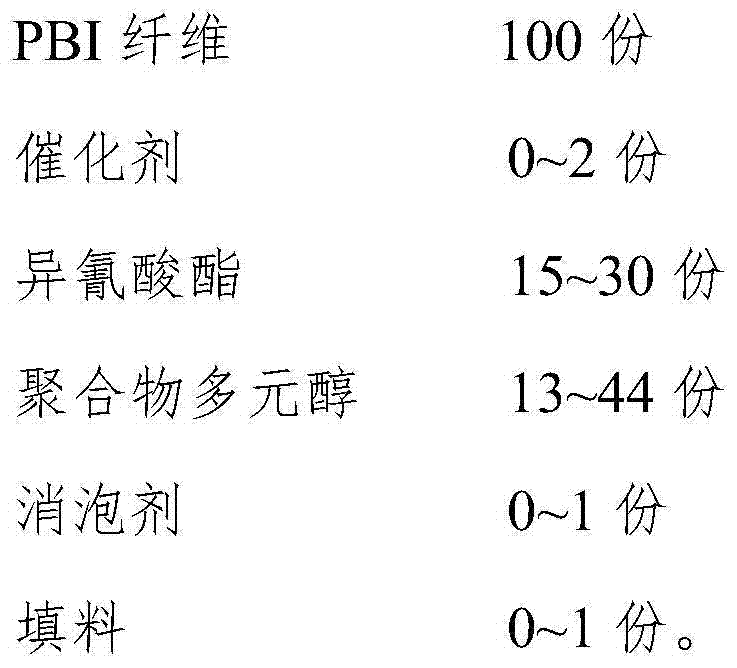

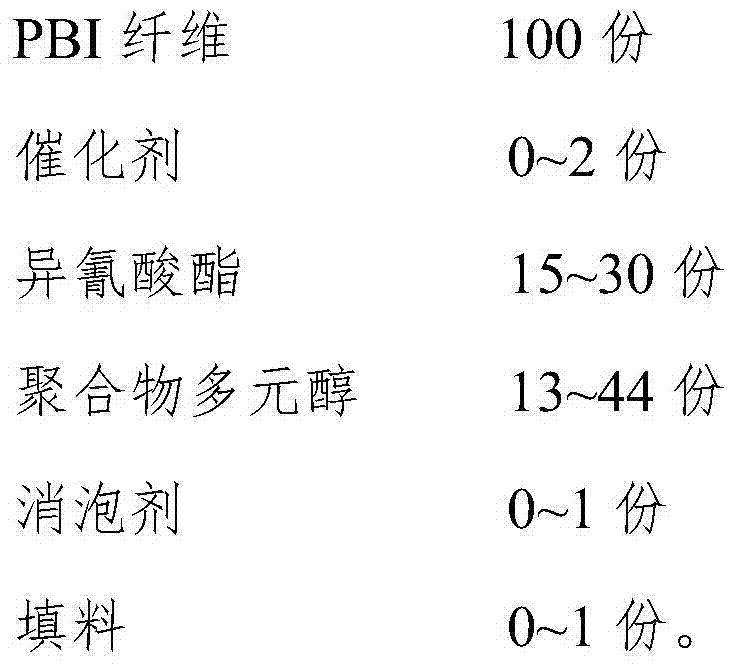

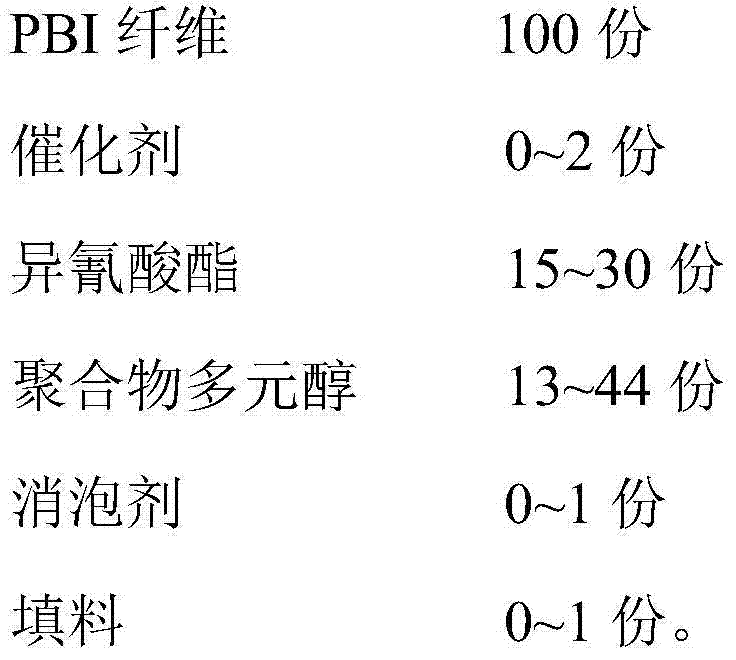

Formula for synthetizing protein-bound iodine (PBI) fiber composite material

A fiber composite material and formulation technology, which is applied in the field of synthetic PBI fiber composite material formulation, can solve the problems of slow curing speed, poor mechanical properties of unsaturated polyester, flammability and explosion, and achieve fast response speed, stable structure, Even wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put polyether 4110 with a molecular weight of 500 and an average functionality of 4 and polyether 210 with a molecular weight of 500 and a functionality of 2 (Suzhou Sinochem International Polyurethane Co., Ltd.) at 120°C for 1-2 hours with a vacuum pump to remove Moisture and other small molecular substances, weighing 2.7Kg and 0.4Kg respectively, 20g zinc naphthenate-bismuth naphthenate compound catalyst (100E, Shanghai Rongrong Chemical Co., Ltd.), 200g defoamer (BD-FT50, Yangzhou Jiangdu District Pharmaceutical Auxiliary Factory), 50g powdered molecular sieve (Shanghai Yuzhou Desiccant Co., Ltd.) were mixed evenly and placed in tank B; 3Kg liquefied MDI (WANNATE1635, Yantai Wanhua Polyurethane Co., Ltd.) was weighed and placed in A tank. Take 20Kg of PBI fibers with a fineness of 90-100g / km, under a certain tension, pass through the mold at a speed of 6-8cm / min, and inject a certain amount of mixed resin glue through the two-component casting system at intervals of ...

Embodiment 2

[0038] Polycaprolactone polyol with a molecular weight of 300 and a functionality of 3 (PCL300, Shanghai Fuxinyuan Chemical Co., Ltd.) and a polytetrahydrofuran ether diol with a molecular weight of 650 and a functionality of 2 (PTMG650, Shanghai Gaoqiao BASF Co., Ltd.) is a difunctional polyether. Use a vacuum pump at 120°C for 1-2 hours to remove water and other small molecular substances. Weigh 2.4Kg and 6.5Kg respectively, and 500g of dibutyltin dilaurate catalyst (commercially available T- 12 catalyst), 100g powdered molecular sieve (Shanghai Yuzhou Desiccant Co., Ltd.) were mixed evenly, and placed in tank B; and 3.5Kg polymeric MDI (5005, Huntsman Chemical Co., Ltd.), were placed in tank A. Take 20Kg of PBI fiber with a fineness of 50-60g / km, pass it through the mold at a speed of 5-6cm / min under a certain tension, and inject a certain amount of mixed resin glue through the two-component casting system at intervals of 1-2min Enter the mold, infiltrate the PBI fiber, the...

Embodiment 3

[0040]The polycaprolactone polyol with a molecular weight of 450 and a functionality of 3 (made in the laboratory) was pumped with a vacuum pump for 1-2 hours at 120°C to remove moisture, and 2.6Kg, 8g of dibutyltin dilaurate catalyst ( Commercially available T-12 catalyst), 50g defoamer (BD-FT50, Yangzhou Jiangdu Pharmaceutical Auxiliary Factory), 200g powdered molecular sieve (Shanghai Yuzhou Desiccant Co., Ltd.) were mixed evenly, and placed in tank B; Take 6Kg polymeric MDI (5005, Huntsman Chemical Co., Ltd.), and place it in tank A. Take 20Kg of PBI fiber with a fineness of 65-75g / km, under a certain tension, pass through the mold at a speed of 5-6cm / min, and inject a certain amount of mixed resin glue through the two-component casting system at intervals of 1-2min Enter the mold, infiltrate the PBI fiber, then cure and leave the mold. According to the national standard GB / T16421-1996, the tensile strength, elongation at break, flexural strength and flexural modulus of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com