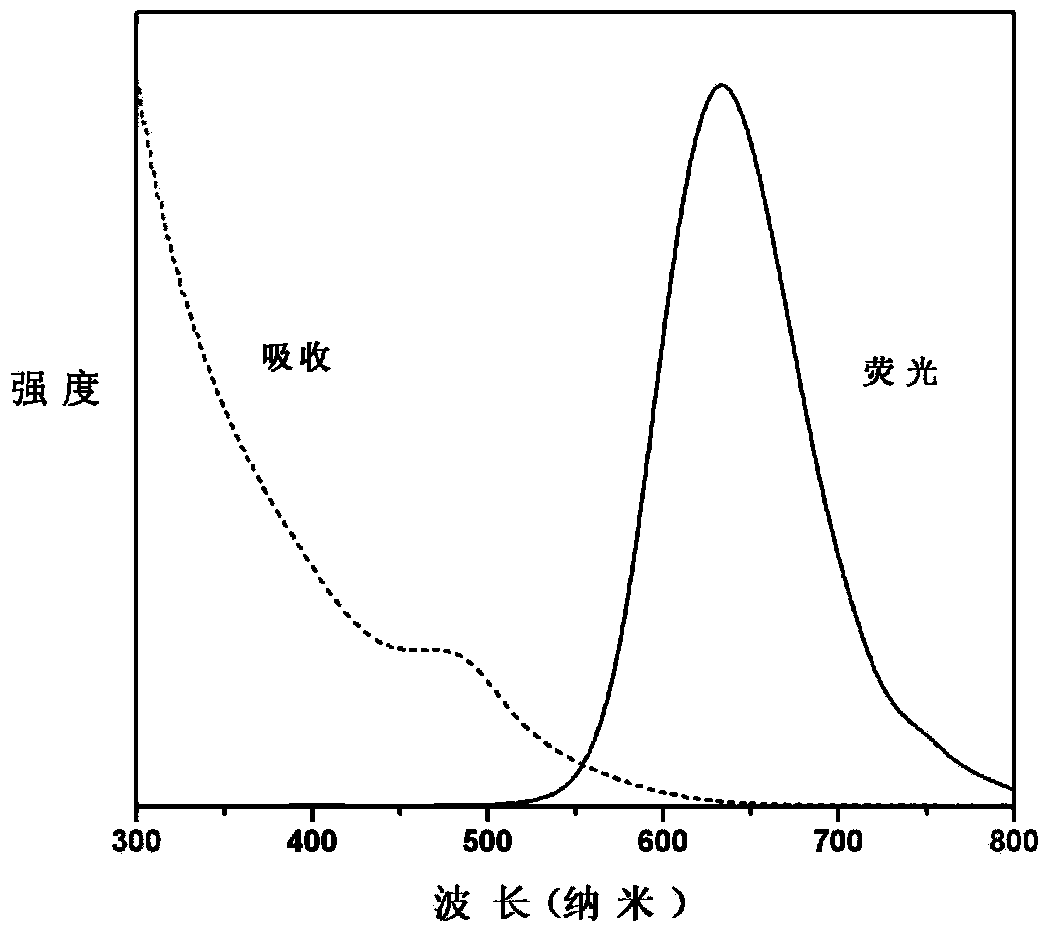

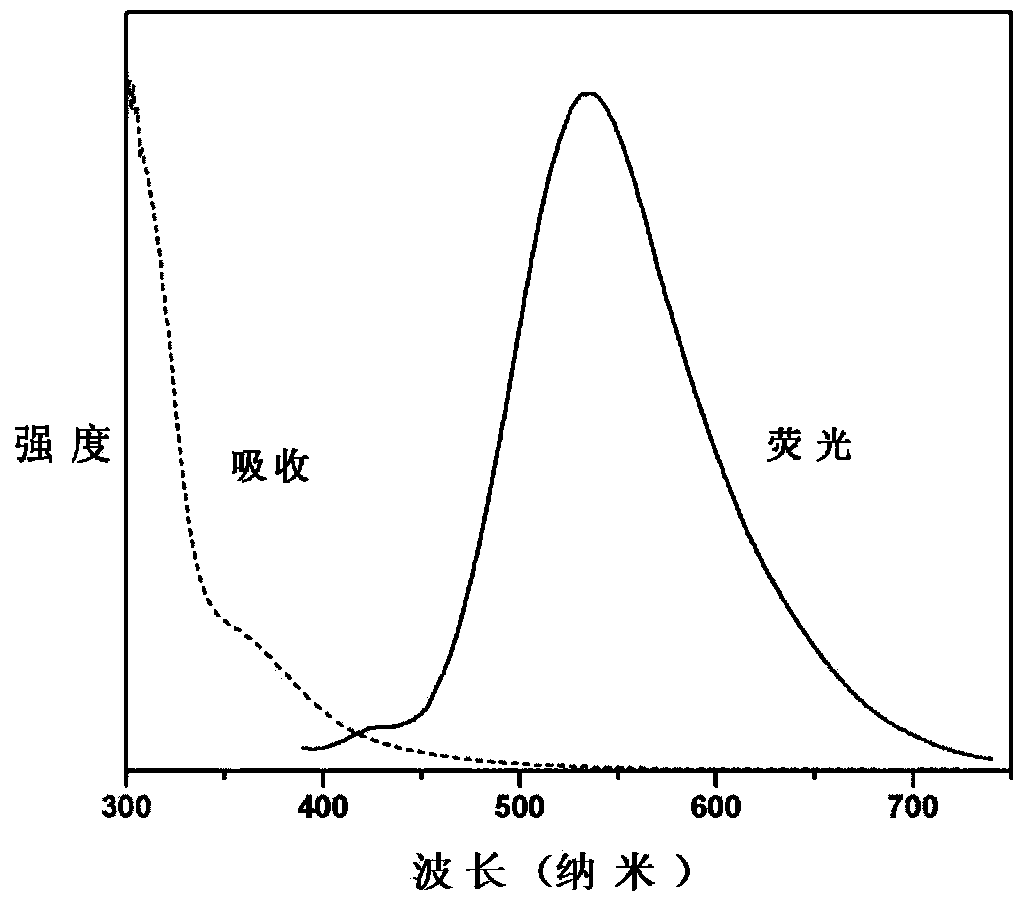

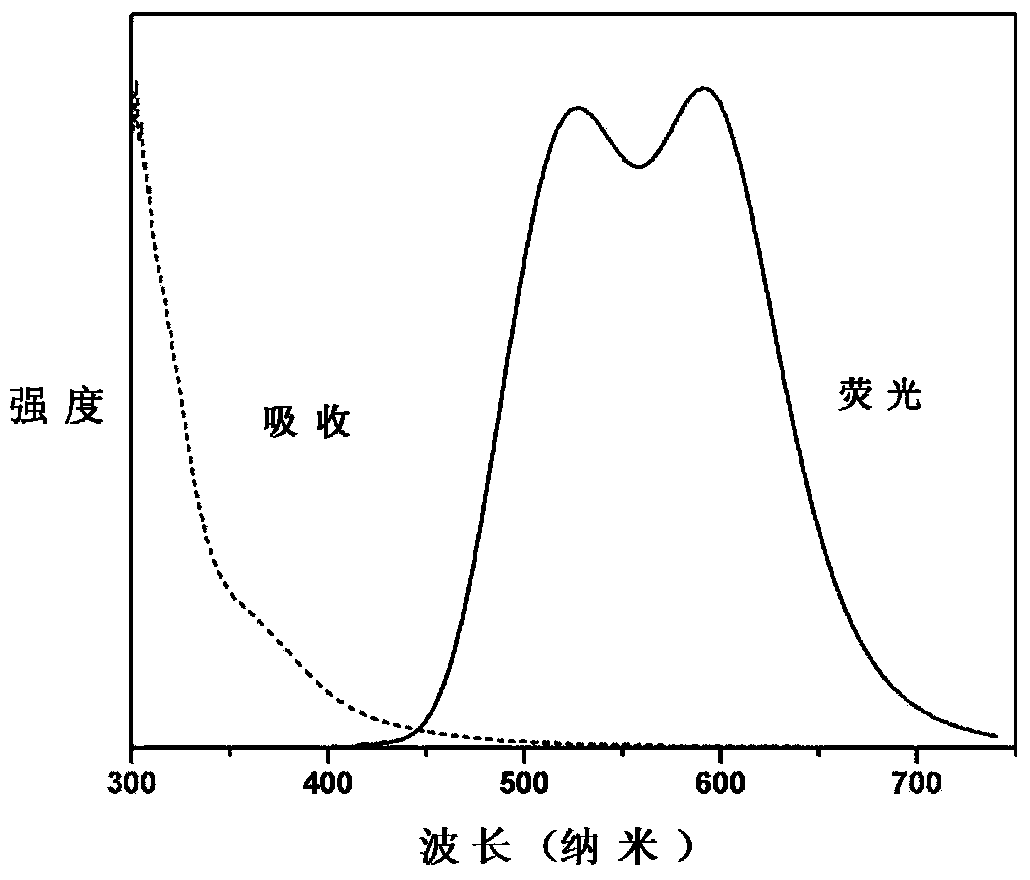

Preparation method of bicolor fluorescent semiconductor nanomaterial based on Mn-doped CuInS2/ZnS

A technology of two-color fluorescence and nanomaterials, applied in the direction of luminescent materials, nanotechnology for materials and surface science, nanotechnology, etc., can solve serious problems such as self-absorption, application limitations, toxicity, etc., and achieve the effect of superior optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of quantum dot nano material comprises the following steps:

[0023] (1) Combine CuI, In(Ac) 3 , Dodecanethiol (DDT), heated to 100°C under argon atmosphere and stirred for 30 minutes, and then heated to 230°C for 5 minutes to obtain CuInS 2 Quantum dot core;

[0024] (2) Cool the above solution to 130°C and inject Zn(Ac) 2 (Zinc acetate) / oleylamine / octadecene (ODE) mixed solution, then heated to 240 ° C for 90 minutes to generate CuInS 2 / ZnS quantum dots, the obtained quantum dots are purified and dissolved in n-hexane;

[0025] (3) Add octadecene (ODE) to the quantum dots purified in (2), and in an argon atmosphere, heat to 150°C and inject Mn(Ac) 2 (manganese acetate) / oleylamine mixed solution, and kept at this temperature for 1 hour, then heated to 240 ° C, injected Zn (Ac) 2 The mixed solution of / oleic acid / DDT / ODE reacted at this temperature for 1 hour and then cooled to room temperature to obtain CuInS 2 / ZnS: Quantum dot nano...

Embodiment 1

[0026] Embodiment 1 Preparation of Quantum Dot Nanomaterials

[0027] Step 1: CuInS 2 Preparation of quantum dots, take 0.0096g (0.05mmol) CuI, 0.146g (0.5mmol) In(Ac) 3 , 5ml DDT in a 100ml three-neck flask, degassed with Ar at 40°C for 15 minutes, then raised the temperature to 100°C and stirred for 30 minutes, then raised the temperature to 230°C for 5 minutes to obtain CuInS 2 Quantum dot core.

[0028] Step 2: Cool the above solution to 130°C and inject Zn(Ac) 2 / oleylamine / octadecene mixed solution, then heated to 240°C for 90 minutes to generate CuInS 2 / ZnS quantum dots, namely CIZS alloy. The injected Zn(Ac) 2 The amount of the quantum dot is 0.9-1mmol, and the injected oleylamine and ODE are respectively 2.5ml and 6ml. The quantum dots are purified and dissolved in n-hexane.

[0029] Step 3: Add 5ml of octadecene (ODE) to the quantum dots obtained in the second step, heat to 150°C in an argon atmosphere, and inject Mn(Ac) 2 / Oleylamine, and keep it at this tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com