Gadolinium (III)-carbon quantum dot and preparation method thereof, and application thereof in magnetic resonance-fluorescence double-modal imaging probe

A technology of carbon quantum dots and mass concentration, which is applied in the application field of gadolinium-carbon quantum dots and its preparation, magnetic resonance-fluorescence dual-mode imaging probes, can solve the problems of complex preparation process, achieve simple preparation method, The effect of enhancing the magnetic resonance signal and requiring less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

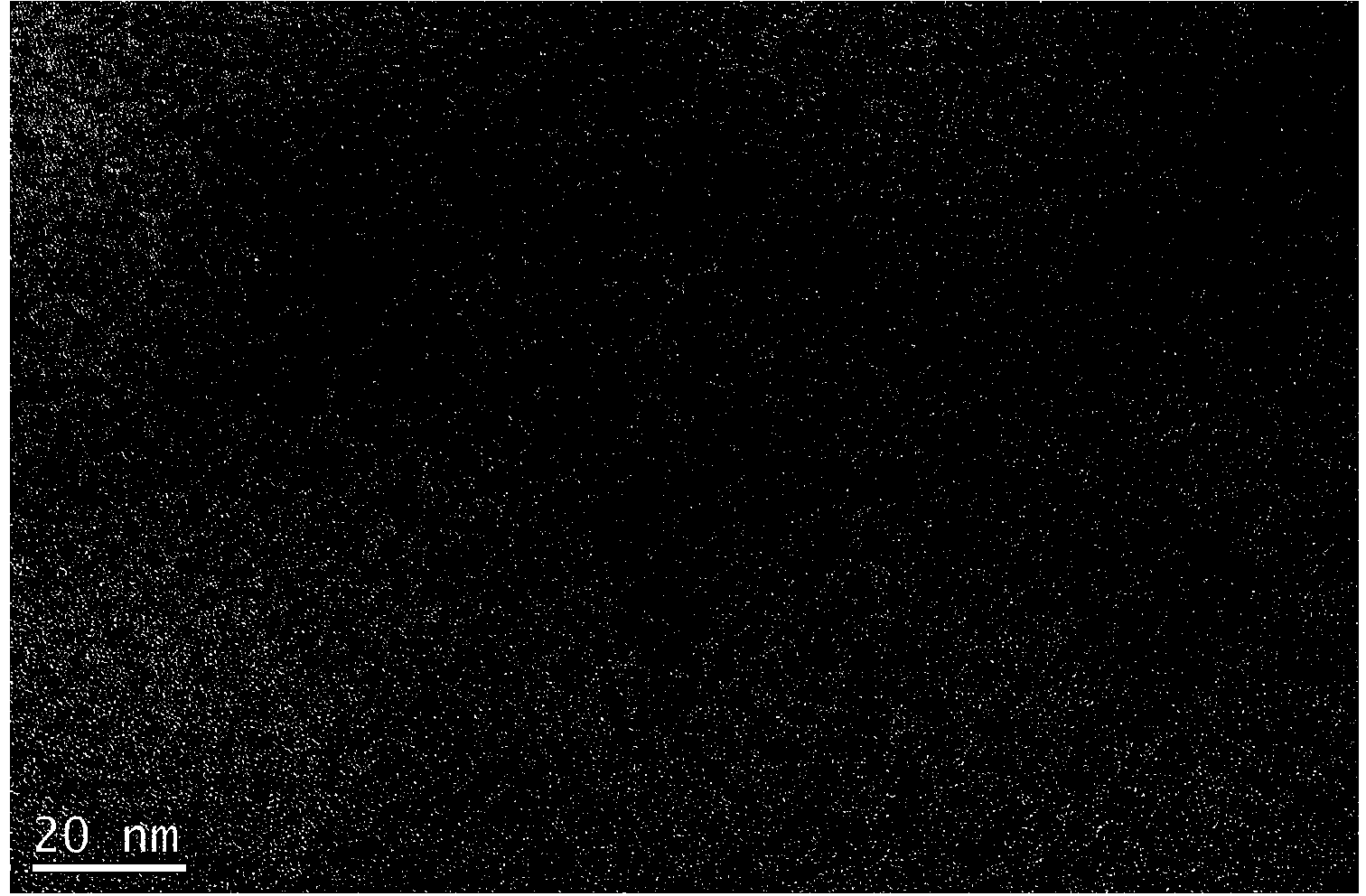

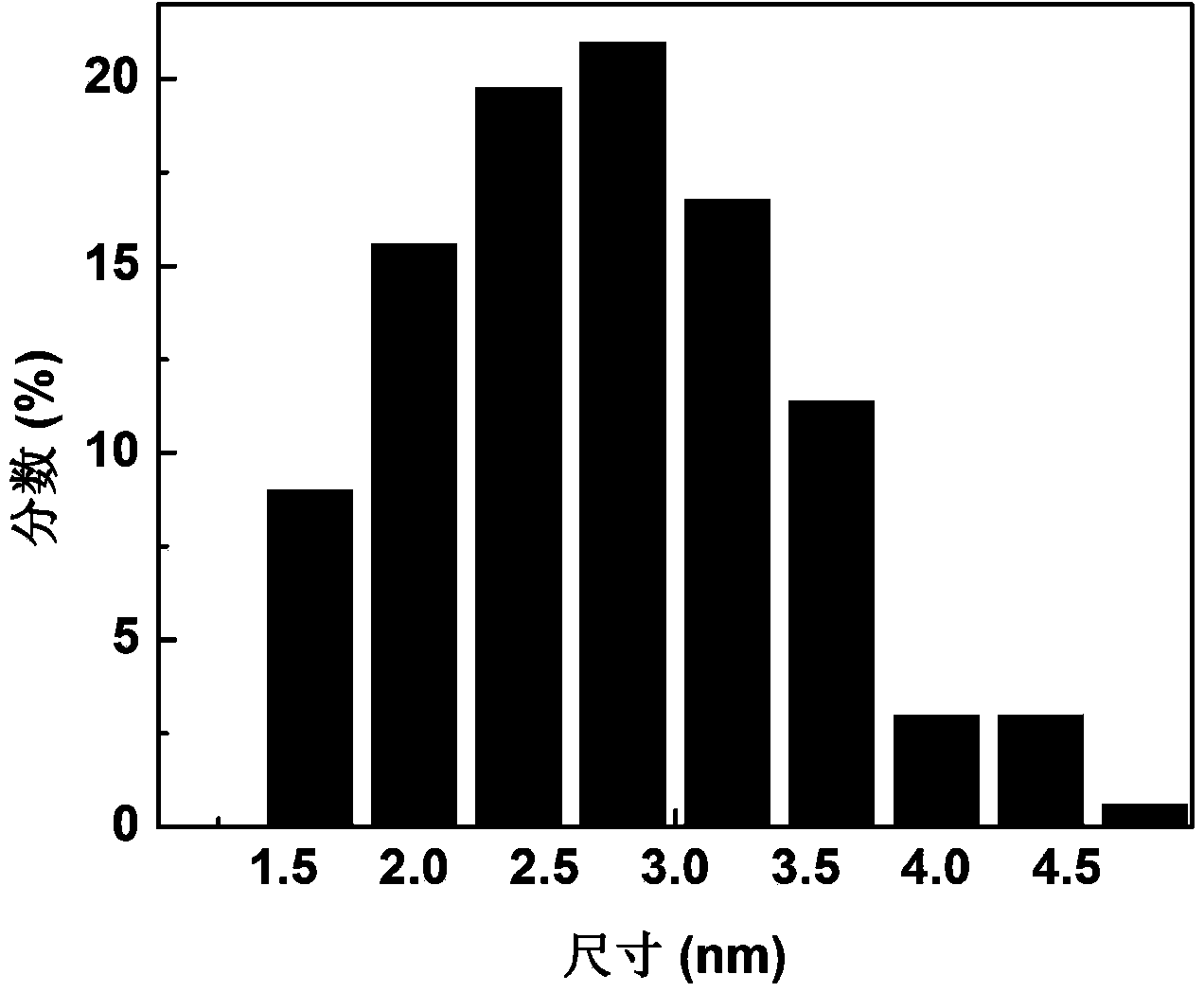

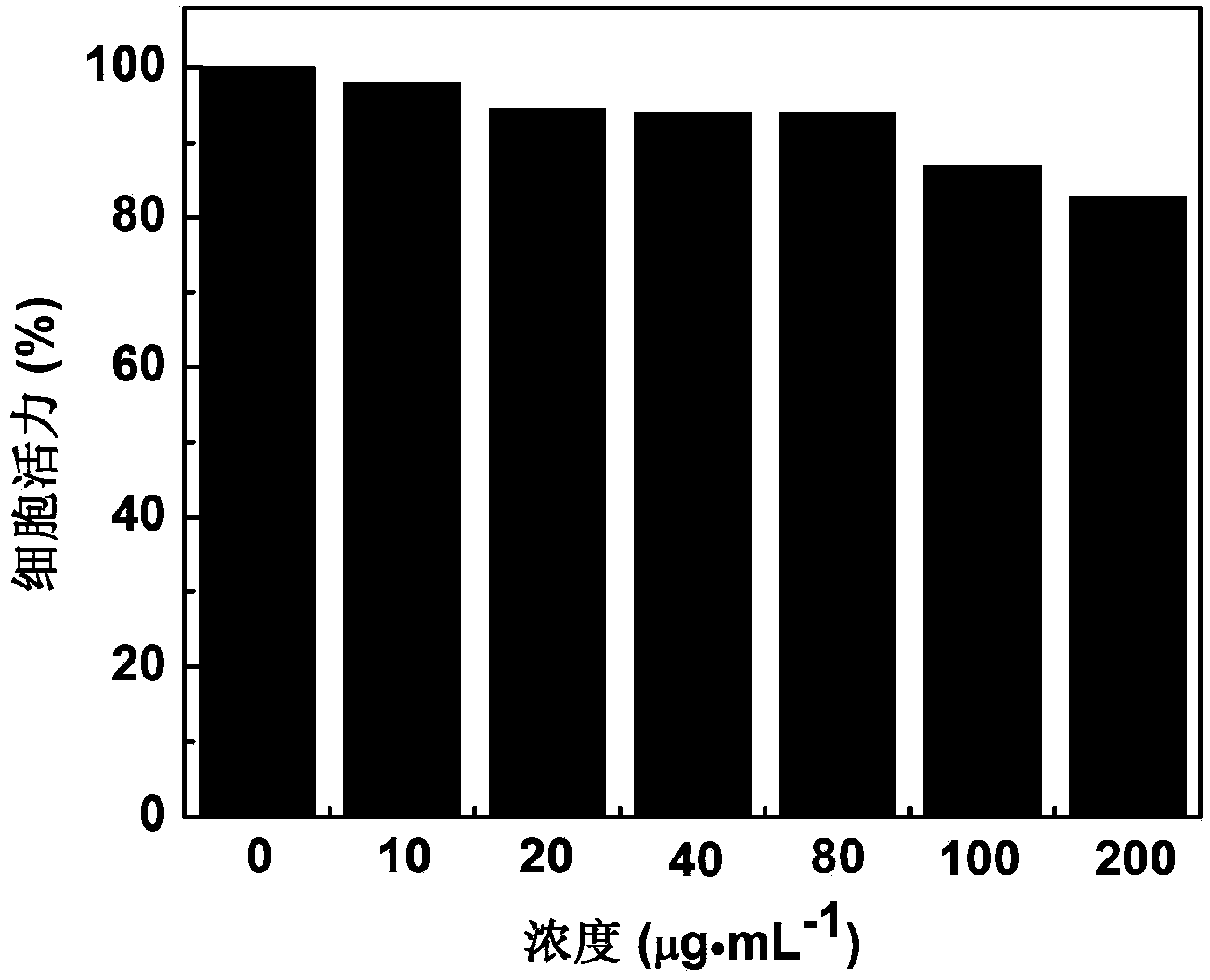

[0035] 1) Using gadolinium diethylenetriamine pentaacetate as a precursor, heat it in a high-temperature resistance furnace with a preset temperature rise program and continuously feed nitrogen to generate pyrolysis products. The temperature rise program of the high temperature resistance furnace is set as: increase the temperature from room temperature to 200 °C at a rate of 1 °C / min, keep at 200 °C for 5 hours, and finally cool down to room temperature.

[0036] 2) Add 2 parts of the pyrolysis product to 20 parts of 0.01M aqueous sodium hydroxide solution, and then place it in an ultrasonic cleaner (power 300W) for dispersive treatment for 20 minutes to obtain a suspension.

[0037] 3) The suspension is filtered through an aqueous microporous membrane with a pore size of 0.22 μm to obtain a filtrate containing gadolinium (Ш)-carbon quantum dots. During the suction filtration process, the filter cake was continuously washed with a 0.01M aqueous sodium hydroxide solution until...

Embodiment 2

[0040] 1) Using gadolinium diethylenetriamine pentaacetate as a precursor, place it in a high-temperature resistance furnace with a preset temperature rise program and continuously feed a mixed gas of helium and nitrogen for heat treatment to generate pyrolysis products. The temperature rise program of the high temperature resistance furnace is set as follows: increase the temperature from room temperature to 400 °C at a rate of 5 °C / min, keep at 400 °C for 3 hours, and finally cool down to room temperature.

[0041] 2) Add 2 parts of the pyrolysis product to 30 parts of 0.05M sodium hydroxide aqueous solution, and then place it in an ultrasonic cleaner (power 400W) for dispersive treatment for 30 minutes to obtain a suspension.

[0042] 3) The suspension is filtered through an aqueous microporous membrane with a pore size of 0.45 μm to obtain a filtrate containing gadolinium (Ш)-carbon quantum dots. During the suction filtration process, the filter cake was continuously washe...

Embodiment 3

[0045] 1) With 1 part of gadolinium diethylenetriamine pentaacetate, 1 part of gadolinium ethylenediamine tetraacetate and 1 part of 1,4,7,10-tetraazacyclododecane-1,4,7,10-tetracarboxylic The mixture of gadolinium acid is the precursor, which is placed in a high-temperature resistance furnace with a preset temperature rise program for heat treatment to generate pyrolysis products. The temperature rise program of the high temperature resistance furnace is set as: increase the temperature from room temperature to 450°C at a rate of 30°C / min, keep at 450°C for 3 hours, and finally cool down to room temperature.

[0046] 2) Add 2 parts of the pyrolysis product to 30 parts of 0.05M potassium hydroxide aqueous solution, and then place it in an ultrasonic cleaner (600W power) for dispersive treatment for 60 minutes to obtain a suspension.

[0047] 3) The suspension is filtered through an aqueous microporous membrane with a pore size of 0.65 μm to obtain a filtrate containing gadolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com