Method used for removing lignocelluloses enzymatic hydrolysate inhibitors

A technology of lignocellulose and enzymatic hydrolysis solution, applied in sugar production, food science, sugar production, etc., can solve the problems of sugar consumption and high enzyme cost, and achieve adsorption capacity recovery, high selectivity, and high removal rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

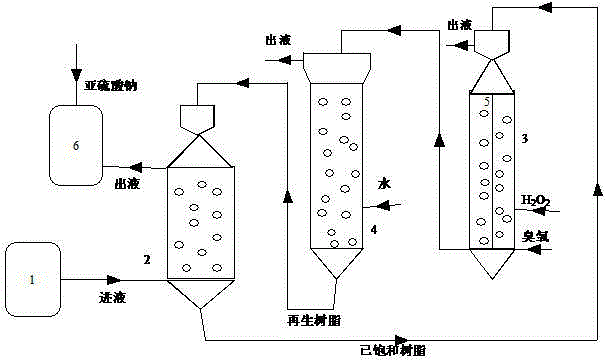

Image

Examples

Embodiment 1

[0032] The steamed material was adjusted to pH 5 with NaOH, added with Shandong Zesheng cellulase, hydrolyzed at 50°C for 120 hours, and centrifuged to obtain the enzymatic hydrolyzate.

[0033] (1) At a flow rate of 3.5mL / min, a pH value of 5, and a temperature of 20°C, the enzymatic hydrolysis solution was put into an adsorption chromatography column of φ30*500mm in an upflow manner, and the resin was NKA-Ⅱ (purchased from Nankai University Chemical Factory ), the filling height of NKA-Ⅱ resin is 300mm, and the absorbance of the outflowing enzymatic hydrolysis solution is detected with a UV spectrophotometer. When the absorbance is less than 0.2, stop entering the enzymatic hydrolysis solution. The adsorption capacity of fresh NKA-II resin was detected by experiments to be 140 mg / g (based on phenol).

[0034] (2) Drain the enzymolysis solution above the chromatography column and return it to the enzymolysis solution tank. The resin layer drops while the liquid is drained, and ...

Embodiment 2

[0041] The steamed material was adjusted to pH 5 with NaOH, added with Shandong Zesheng cellulase, hydrolyzed at 50°C for 120 hours, and centrifuged to obtain the enzymatic hydrolyzate.

[0042] (1) At a flow rate of 5.0mL / min, a pH value of 5, and a temperature of 20°C, the enzymatic hydrolysis solution was poured into a φ30*500mm adsorption chromatography column in an upflow manner, and the resin was NKA-Ⅱ (purchased from Nankai University Chemical Plant) , The filling height of NKA-Ⅱ resin is 300mm, and the absorbance of the outflowing enzymatic hydrolysis solution is detected with a UV spectrophotometer. When the absorbance is less than 0.2, stop entering the enzymatic hydrolysis solution. The adsorption capacity of NKA-II resin was detected by experiments to be 140 mg / g (based on phenol).

[0043] (2) Drain the enzymolysis solution above the chromatography column and return it to the enzymolysis solution tank. The resin layer drops while the liquid is drained, and part of...

Embodiment 3

[0050] The steamed material was adjusted to pH 5 with NaOH, added with Shandong Zesheng cellulase, hydrolyzed at 50°C for 120 hours, and centrifuged to obtain the enzymatic hydrolyzate.

[0051] (1) Enter the enzymatic hydrolysis solution into the adsorption chromatography column of φ30*500mm in the upflow mode at the flow rate of 7mL / min, pH value of 5, and temperature of 20°C. The resin is NKA-Ⅱ (purchased from Nankai University Chemical Plant), The filling height of NKA-Ⅱ resin is 300mm. Use an ultraviolet spectrophotometer to detect the absorbance of the outflowing enzymolysis solution. When the absorbance is less than 0.2, stop entering the enzymolysis solution. The adsorption capacity of fresh NKA-II resin is 140 mg / g (based on phenol) as detected by experiments.

[0052] (2) Drain the enzymolysis solution above the chromatography column and return it to the enzymolysis solution tank. The resin layer drops while the liquid is drained, and part of the saturated resin is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com