Confocal optical scanner

A confocal and scanner technology, applied in the field of biomedical microscopic imaging, can solve the problems of slow scanning speed, uneven illumination intensity, scanning line interference, etc. The effect of uneven brightness and darkness of the image, simple installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

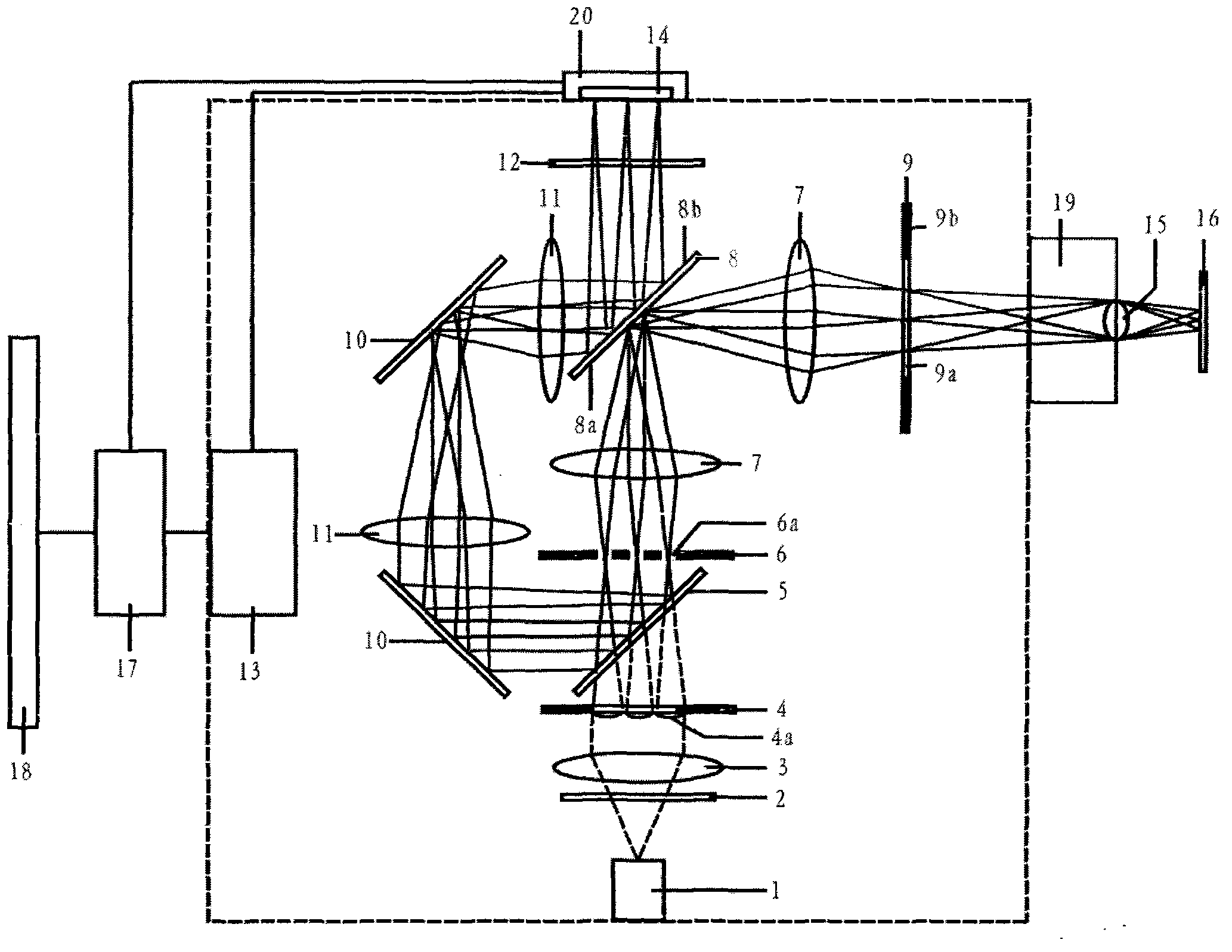

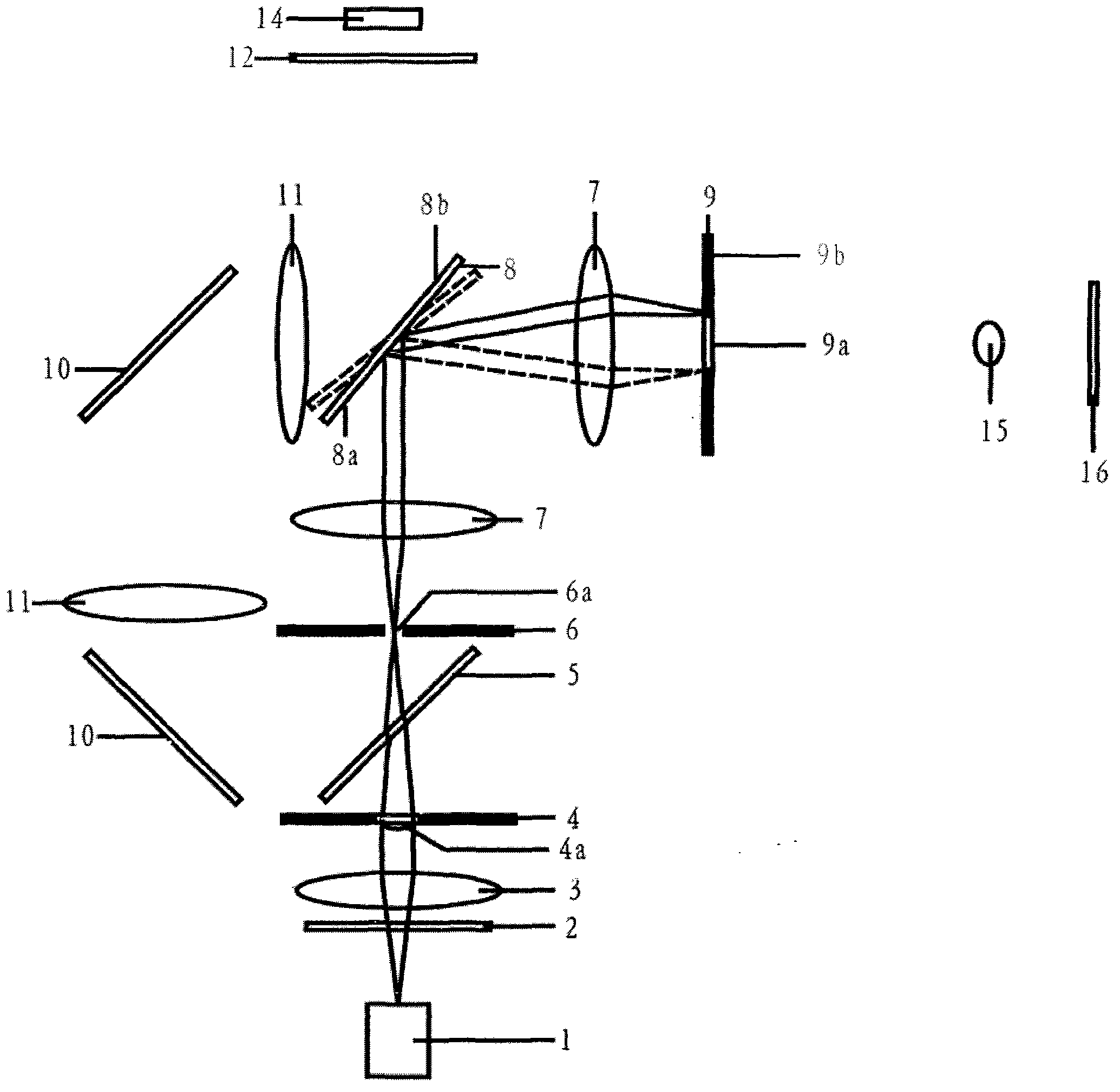

[0052] Figure 2a and 2b It is a schematic diagram of the first confocal optical scanner related to the present invention, wherein the first reflection surface 8a, the second reflection surface 8b of the scanning galvanometer 8 and the total reflection mirror group 10 are all plane reflections.

[0053] like Figure 2a , in this embodiment, before the area array detector 20 (not shown) starts to expose, the controller 13 (not shown) controls the scanning vibrating mirror 8 to stay in the forward or reverse maximum rotation angle position; the light from the light source 1 Emitted, through the excitation color filter 2, the illumination lens group 3, the microlens 4a on the microlens array 4, the dichroic beam splitter 5 and the pinhole 6a on the pinhole array 6 to form a plurality of excitation point light sources; The image is imaged by the delay lens group 7 and reflected by the first reflective surface 8a of the scanning galvanometer 8 on the opaque portion 9b of the cut-...

Embodiment 2

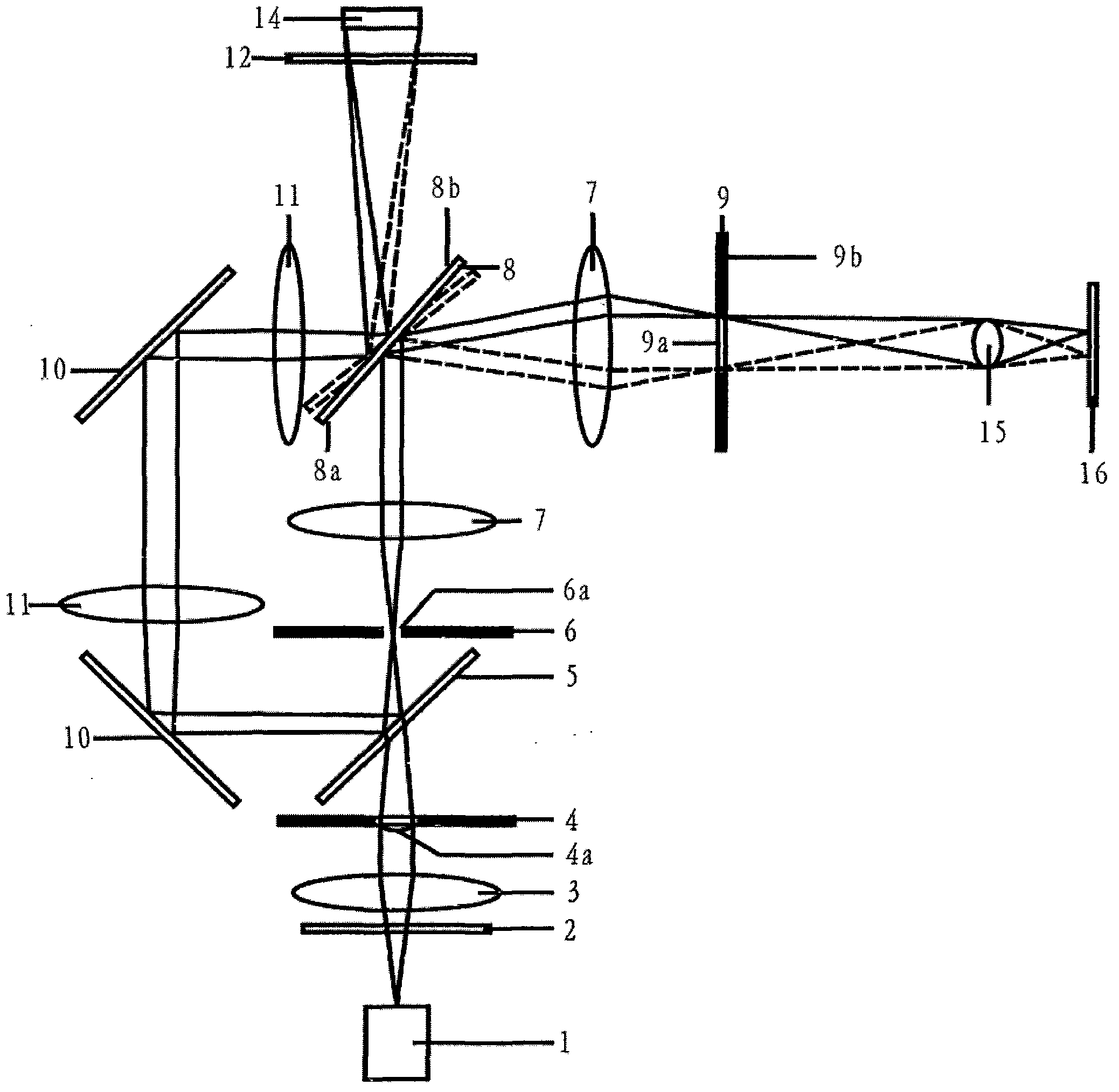

[0058] image 3 It is a schematic structural diagram of the second confocal optical scanner related to the present invention, and the difference from Embodiment 1 is as follows: the first reflective surface 8a, the second reflective surface 8b, and the first reflective surface 8a of the scanning galvanometer 8 The total reflection mirror 10 between the pinhole array 6 is a concave reflection, which can replace the delay lens group 7 and the imaging lens group 11 of the embodiment 1 to image the pinhole array 6, the first reflective surface 8a and the first reflective surface The imaging magnification of the total reflection mirror 10 between 8a and the pinhole array 6 is M2. Because the delay lens group 7 and the imaging lens group 11 are reduced, there are fewer optical interfaces in the optical path of this embodiment, and higher light efficiency can be obtained.

Embodiment 3

[0060] Figure 4 It is a schematic structural view of the third confocal optical scanner related to the present invention, and the difference from Embodiment 2 is as follows: the first reflection surface 8a of the scanning galvanometer 8 and the total reflection mirror group 10 are concave reflection, the second reflection Surface 8b is planar reflection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com