Method for determining germanium content of cobalt-nickel slag by atomic fluorescence spectrometry

A technology of atomic fluorescence spectroscopy and atomic fluorescence, which is applied in the field of metallurgical industry analysis, can solve the problems of large interference of analysis results and low accuracy of detection results, and achieve the effects of low environmental requirements, fast measurement and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

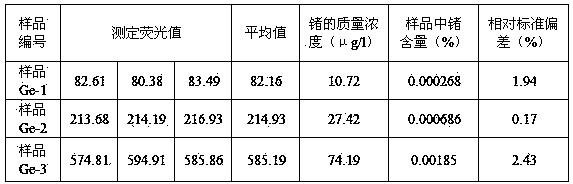

Examples

Embodiment 1

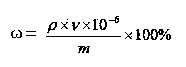

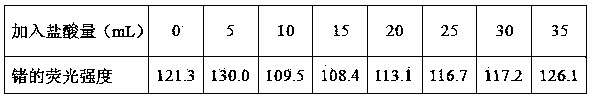

[0035] A method for measuring germanium content in cobalt-nickel slag by atomic fluorescence spectrometry, comprising the following steps:

[0036] (1) Preparation of germanium stock solution: Accurately weigh 1.0000g of metal germanium and place it in a beaker with a volume of 100 mL, add 1 mL of 30% H 2 o 2 , 1 mL of ammonia water with a density of 0.9g / mL, 20 mL of high-purity water, heated and dissolved in a boiling water bath, cooled to room temperature, and transferred to a volumetric flask with a volume of 1000 mL, diluted to the mark with high-purity water, and shaken well, the germanium in the obtained germanium stock solution The content is 1mg / mL;

[0037] (2) Pipette the germanium stock solution to prepare a germanium standard solution: pipette the germanium stock solution and dilute step by step according to the volume relationship of 10 times, dilute to the scale of the container with a phosphoric acid solution with a volume ratio of 5%, shake well, and obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com