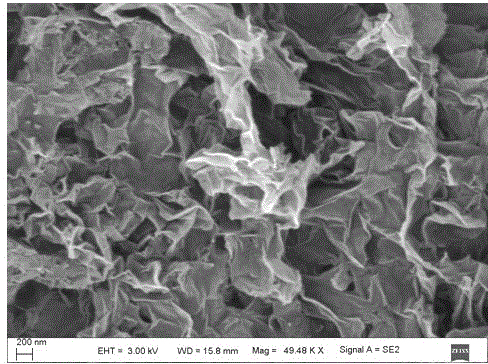

Preparation and application of a carbon nanosheet material with graphene-like sheet structure

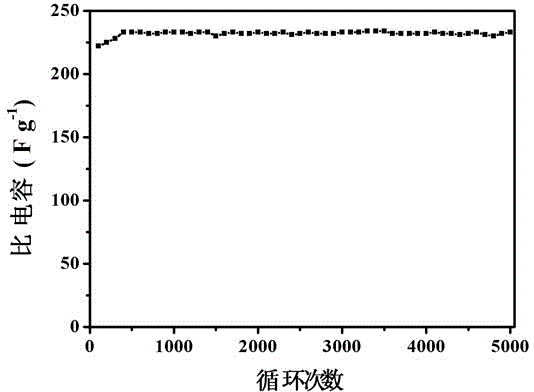

A graphene sheet and carbon nanosheet technology, applied in the field of carbon nanomaterials, can solve the problems of high equipment requirements and low output, and achieve the effects of low cost, large specific capacitance and high cycle efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

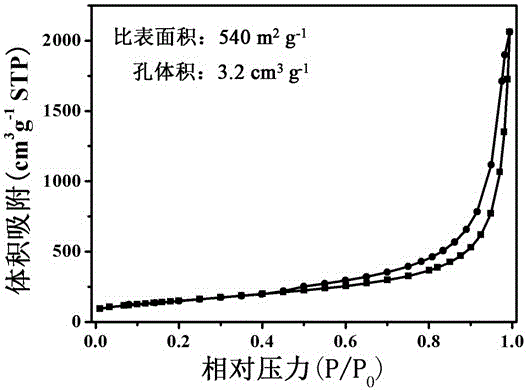

Embodiment 1

[0026] Weigh 3 g of phenolic resin, wash with deionized water to remove impurities, then wash with 1 mol / L NaOH solution, deionized water and ethanol for several times, dry at 60°C and fully mix with 9g KOH; For tube furnaces, at N 2 Protected, preactivated at 250°C for 4 h, then heated to 600°C for carbonization for 6 h; taken out and exposed to air at 200°C (in a tube furnace, without N 2 protection) for secondary activation (calcination) for 3 h. The obtained carbon material was soaked in 1 mol / L HCl solution at 80°C for 12h, then cooled to room temperature, filtered, washed with deionized water until neutral, and dried at 60°C to obtain carbon nanosheets with a graphene-like structure. The carbon nanosheets have a specific surface area of 320 m 2 g -1 , pore volume up to 1.9cm 3 g -1 . After testing, the carbon nanosheets are used as supercapacitor electrode materials, and the specific capacitance in 6mol / L KOH electrolyte is 198Fg -1 .

Embodiment 2

[0028] Weigh 2 g of ion exchange resin, wash with deionized water to remove impurities, and then wash with 2 mol / L NaOH solution, deionized water and ethanol for several times, dry at 60 °C and mix with 4 g Ca(OH ) 2 Mix thoroughly; place in a tube furnace under N 2 Protection, pre-activation at 350°C for 4 hours, then heating to 700°C for carbonization for 6 hours; take it out and expose it to air at 200°C (same as before) for secondary activation for 3 hours. Soak the obtained carbon material in HCl solution (3 mol / L) at 80°C for 24h, then cool to room temperature, filter, wash with deionized water until neutral, and dry at 60°C to obtain carbon nanosheets with a graphene-like structure . The carbon nanosheets have a specific surface area of 420 m 2 g -1 , with a pore volume up to 2.3 cm 3 g -1 . After testing, the carbon nanosheets are used as supercapacitor electrode materials, and the specific capacitance in 6mol / L KOH electrolyte is 225Fg -1 .

Embodiment 3

[0030] Weigh 3 g of urea-formaldehyde resin, wash with deionized water to remove impurities, then wash with NaOH solution with a concentration of 2mol / L, deionized water and ethanol several times, dry at 60°C and mix with 6 g Ca(OH) 2 Mix well; place in a tube furnace under N 2 Protection, pre-activation at 450 °C for 4 h, and then heating to 750 °C for carbonization for 6 h; after removal, the carbonized material was exposed to air at 200 °C (same as before) for secondary activation for 3 h. Soak the obtained carbon material in HCl solution (3 mol / L) at 80°C for 12h, then cool to room temperature, filter, wash with deionized water until neutral, and dry at 60°C to obtain carbon nanosheets with a graphene-like structure . The carbon nanosheets have a specific surface area of 450 m 2 g -1 , with a pore volume up to 2.5 cm 3 g -1. After testing, the carbon nanosheets are used as supercapacitor electrode materials, and the specific capacitance in 6mol / L KOH electrolyte ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore volume | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com