Graphene-carrying phyllosilicate nano composite material and preparation method thereof

A technology of nanocomposite material and layered silicate, which is applied in the field of nanocomposite material and its preparation, can solve the troublesome process of removing the stabilizer, cannot be preserved for a long time, and affects the properties of graphene, etc., and achieves the goal of preparing The method is simple and environmentally friendly, good straightness, and the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

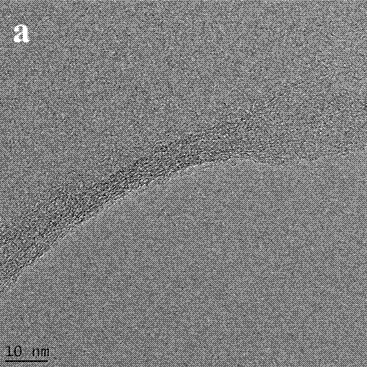

Image

Examples

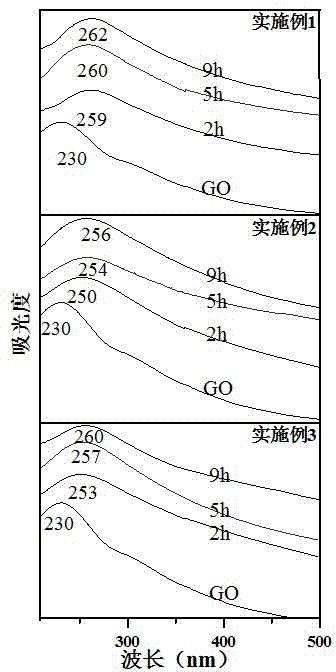

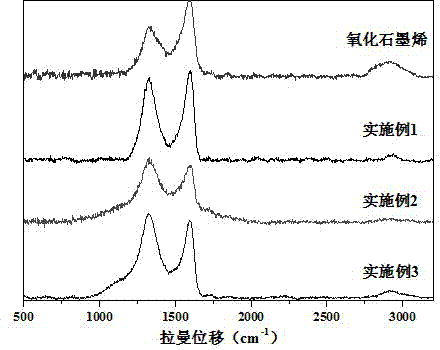

Embodiment 1

[0026] Organic rectorite is obtained by reacting 0.1 CEC cetyltrimethylammonium bromide and calcium-based rectorite under microwave conditions, and then organic rectorite and graphene oxide (mass ratio is 5:1) respectively dispersed in water, wherein the organic rectorite solution was heated and stirred overnight at room temperature, and the graphene oxide was first dispersed ultrasonically, and the organic rectorite dispersion was added dropwise to the graphene oxide solution and dispersed ultrasonically; the organic rectorite After ultrasonication of the mixed solution of graphene / graphene oxide, the pH was adjusted to 8, and the carboxymethyl chitosan quaternary ammonium salt solution A: 0.4%, B: 4.0% (both mass percentages) were prepared, heated and stirred in an oil bath to 85 °C, and the A solution Add graphene oxide dropwise for 5 minutes. After half an hour of reaction, perform ultrasonic operation to disperse the solution evenly; continue to add solution B dropwise for 3...

Embodiment 2

[0028] Organic rectorite is obtained by reacting 0.5 CEC dodecyltrimethylammonium bromide and calcium-based rectorite under microwave conditions, and then organic rectorite and graphene oxide (mass ratio: 10:1) are respectively Dispersed in water, wherein the organic rectorite solution was heated and stirred overnight at room temperature, the graphene oxide was first ultrasonically dispersed, and the organic rectorite dispersion was added dropwise to the graphene oxide solution and ultrasonically dispersed; the organic rectorite / The pH of the graphene oxide mixed solution was adjusted to 9 after ultrasonication, and the carboxymethyl chitosan quaternary ammonium salt solution A: 0.5%, B: 3.0% (both mass percentages) were prepared, heated and stirred in an oil bath to 90°C, and the A solution was dropped Add graphene oxide, the dropping time is 20 min, and after 45 min of reaction, perform ultrasonic operation to disperse the solution evenly; continue to drop B solution, the dr...

Embodiment 3

[0030] Organic rectorite is obtained by reacting propylene bis(octadecyldimethylammonium chloride) with calcium-based rectorite under microwave conditions at 3.0 CEC, and then organic rectorite and graphene oxide (mass ratio 20:1) were respectively dispersed in water, wherein the organic rectorite solution was heated and stirred overnight at room temperature, the graphene oxide was first ultrasonically dispersed, and the organic rectorite dispersion was added drop by drop to the graphene oxide solution and ultrasonically dispersed; The pH of the organic rectorite / graphene oxide mixed solution was adjusted to 10 after ultrasonication, and the carboxymethyl chitosan quaternary ammonium salt solution A: 0.6%, B: 2.0% (both mass percentages) were prepared, heated and stirred in an oil bath to At 90 ℃, A solution was added dropwise to graphene oxide for 10 min, and after 1 hour of reaction, ultrasonic operation was performed to disperse the solution evenly; continue to drop B soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com