Method for Batch Synthesis of Polymer Double-sided Particles Using Double-sided Emulsion as Template

A technology for synthesizing polymers and double-sided emulsions, which is applied in the field of synthetic polymer double-sided particles, can solve the problems of narrow particle size control range, limited yield of double-sided particles, and limited output, so as to reduce production costs and avoid precision instruments. The dependence of equipment and complex processes, the effect of fast and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1, will dissolve the tripropylene glycol diacrylate (TPGDA) monomer of 4wt% photoinitiator 1-hydroxycyclohexyl phenyl ketone (HCPK), silicone oil (SO), concentration is the polyoxyethylene dehydration of 5wt% The three phases of the aqueous solution of sorbitan monooleate (Tween80) were mixed at a mass ratio of 0.10:0.57:0.33. 2 g of the mixed solution was placed in a 10 ml glass tube and emulsified in a disperser with a fractional rate of 7000 rpm for 2 min.

[0044] 2. Put the double-sided emulsion obtained in step 1) under ultraviolet light with a power of 100w for 20 minutes to initiate TPGDA monomer phase polymerization.

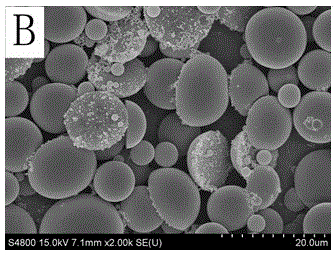

[0045] 3. The mixture containing double-sided cap-shaped polymer particles obtained in step 2) was washed 4 times with acetone, and the solid phase was dried at room temperature for 12 hours to obtain double-sided cap-shaped polymer particles.

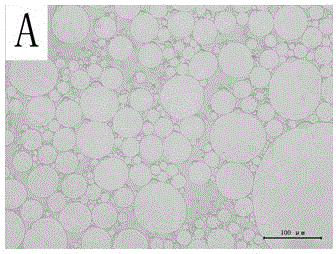

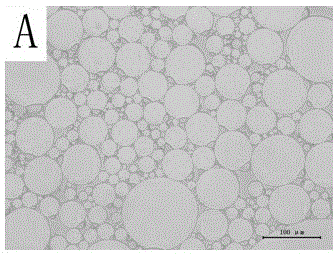

[0046] 4. Verification: The structure of the prepared double-sided emulsion can be observed through an...

Embodiment 2

[0048] 1, will dissolve the tripropylene glycol diacrylate (TPGDA) monomer of 4wt% photoinitiator 1-hydroxycyclohexyl phenyl ketone (HCPK), silicone oil (SO), concentration be the polyoxyethylene dehydration of 6wt% The aqueous solution of sorbitan monooleate (Tween80) was mixed at a mass ratio of 0.13:0.54:0.33, 2 g of the mixed solution was placed in a 10 ml glass tube, and emulsified in a disperser with a fractional rate of 7000 rpm for 2 min.

[0049] 2. Put the double-sided emulsion obtained in step 1) under ultraviolet light with a power of 300w for 8 minutes to initiate TPGDA monomer phase polymerization.

[0050] 3. Wash the mixture containing double-sided cap-shaped polymer particles obtained in step 2) four times with acetone, and dry at room temperature for 12 hours to obtain double-sided cap-shaped polymer particles.

[0051] 4. Verification: The structure of the prepared double-sided emulsion can be observed through an optical microscope, such as image 3 As shown,...

Embodiment 3

[0053] 1. Tripropylene glycol diacrylate (TPGDA) monomer, silicone oil (SO) or fluorocarbon oil dissolved with 4wt% photoinitiator 1-hydroxycyclohexyl phenyl ketone (HCPK), concentration is 8wt% The three phases of polyoxyethylene sorbitan monooleate (Tween80) aqueous solution are mixed at a mass ratio of 0.17:0.50:0.33, 2g of the mixed solution is placed in a 10ml glass tube, and emulsified in a disperser with a fractional rate of 7000rpm 2min.

[0054] 2. Put the double-sided emulsion obtained in step 1) under ultraviolet light with a power of 200w for 15 minutes to initiate TPGDA monomer phase polymerization.

[0055] 3. Wash the mixture containing double-sided cap-shaped polymer particles obtained in step 2) four times with acetone, and dry at room temperature for 12 hours to obtain double-sided cap-shaped polymer particles.

[0056] 4. Verification: The structure of the prepared double-sided emulsion can be observed through an optical microscope, such as Figure 5 As sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com