Polyaryletherketone composite material and preparation method thereof and sealing ring made of polyaryletherketone composite material

A composite material, polyaryletherketone technology, applied in the field of sealing rings, polyaryletherketone composite materials, and the production of this material, can solve the problems of rubber seals that are easy to age and deform, increase material brittleness, and affect seal compensation performance, etc., to achieve Excellent physical and mechanical properties and chemical corrosion resistance, improve self-lubrication and wear resistance, reduce friction coefficient and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

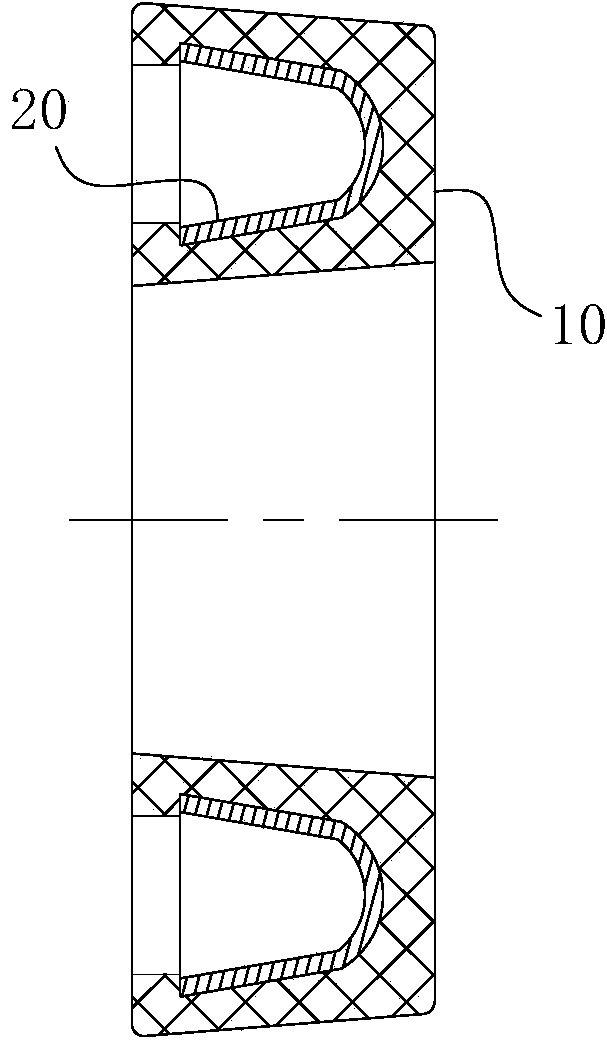

Image

Examples

Embodiment 1

[0036] 1), surface treatment

[0037] Get 5 parts by weight of soft carbon powder, stir in a blender, and spray gamma-aminopropyl triethoxysilane coupling agent solution at the same time, the amount of gamma-aminopropyl triethoxysilane coupling agent is the weight of soft carbon powder 1%, the weight percentage of γ-aminopropyltriethoxysilane coupling agent in the γ-aminopropyltriethoxysilane coupling agent solution is 20%, the weight percentage of ethanol is 72%, water The weight percentage is 8%; take it out after stirring for 15-20 minutes, dry at 130°C for 2 hours, and pass through a 200-300-mesh standard sieve after crushing to obtain surface-treated soft carbon powder, which is ready for use.

[0038] 2), mixing

[0039] Add 95 parts by weight of copolymerized aryl ether ketone resin and 5 parts by weight of surface-treated soft carbon powder into the mixer, stir evenly to obtain a mixture, and take it out for use.

[0040] 3), drying

[0041] Put the mixture obtained...

Embodiment 2

[0045] 1), surface treatment

[0046] Get 8 parts by weight of soft carbon powder, stir in a blender, and spray gamma-aminopropyl triethoxysilane coupling agent solution at the same time, the amount of gamma-aminopropyl triethoxysilane coupling agent is the weight of soft carbon powder 1%, the weight percentage of γ-aminopropyltriethoxysilane coupling agent in the γ-aminopropyltriethoxysilane coupling agent solution is 20%, the weight percentage of ethanol is 72%, water The weight percentage is 8%; take it out after stirring for 15-20 minutes, dry at 130°C for 2 hours, and pass through a 200-300-mesh standard sieve after crushing to obtain surface-treated soft carbon powder, which is ready for use.

[0047] 2), mixing

[0048] Add 92 parts by weight of copolymerized aryl ether ketone resin and 8 parts by weight of surface-treated soft carbon powder into the mixer, stir evenly to obtain a mixture, take it out for use.

[0049] 3), drying

[0050] Put the mixture obtained in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com