Composition of food-grade lubricating grease and preparation method thereof

A food-grade, lubricating grease technology, which is applied in the chemical field, can solve the problems of complicated preparation process of complex calcium sulfonate-based lubricating grease, inability to apply food mechanical equipment lubrication, and inability to meet the lubrication requirements of high-temperature equipment, etc., to achieve mechanical stability and Poor water erosion resistance, improved structural stability and water erosion resistance, and dense fiber structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 2200g, 40 ℃ viscosity is 105mm 2 / s of food-grade white oil, 235.3g of first-grade stearic acid, 71g of benzoic acid and 40g of simethicone oil were successively put into a 5L refining reaction kettle, stirred and heated to 80°C, and then added at a rate of 6.0g / min 182.7g of aluminum trimer of isopropoxide, compound reaction at 90°C for 75min, add 500g of the above-mentioned food-grade white oil, continue to heat up to 195°C, keep stirring at 195°C for 60min, then add 600g of food-grade white oil to cool down Cool, when the temperature drops to 95°C, add 85g of calcium carbonate micropowder, 12g of dilauryl thiodipropionate and 40g of Span-80 in sequence, stir and mix evenly, grind three times with a three-roll mill to obtain the finished product . The performance of the lubricating grease that present embodiment makes is listed in Table 1.

Embodiment 2

[0036] 2300g, 40 ℃ viscosity is 220mm 2 / s food-grade synthetic oil PAO, 227.5g of secondary stearic acid, 78.5g of benzoic acid and 32g of simethicone oil were successively put into a 5L refining reactor, stirred and heated to 85°C, and then heated at 5.5g / min Add 178g of aluminum trimer of isopropoxide at a high speed, and compound reaction at 95°C for 60 minutes, then add 400g of the above-mentioned food-grade PAO, continue to heat up to 190°C, keep stirring at 190°C for 90 minutes, and then add 600g of the above-mentioned food-grade synthetic oil PAO. When the temperature is lowered to 85°C, add 120g of calcium carbonate micropowder, 15g of dilauryl thiodipropionate and 50g of Span-80 in sequence, stir and mix evenly, and grind three times with a three-roll mill to obtain a finished product. The performance of the lubricating grease that present embodiment makes is listed in Table 1.

Embodiment 3

[0038] 2200g, 40 ℃ viscosity is 320mm 2 / s mixed base oil (70# food-grade white oil mixed with PAO40 at a ratio of 15%:85%), 233g of first-grade stearic acid, 75g of benzoic acid and 60g of phenylmethyl silicone oil were put into the 5L refining reaction kettle in turn, Stir and heat to 80°C, then add 168g of aluminum isopropoxide trimer at a rate of 8.0g / min, and after compound reaction at 90°C for 90 minutes, add 500g of the above mixed oil, continue to heat up to 185°C, and at 185°C Insulate and stir for 60 minutes, then add 700 g of the above mixed oil. When the temperature drops to 90°C, add 100g of calcium carbonate micropowder, 12g of dilauryl thiodipropionate and 45g of Span-80 in sequence, stir and mix evenly, and grind three times with a three-roll mill to obtain a finished product. The performance of the lubricating grease that present embodiment makes is listed in Table 1.

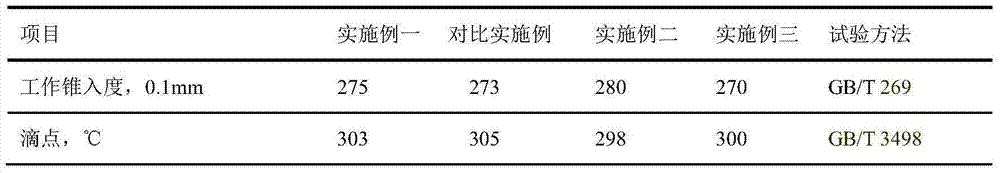

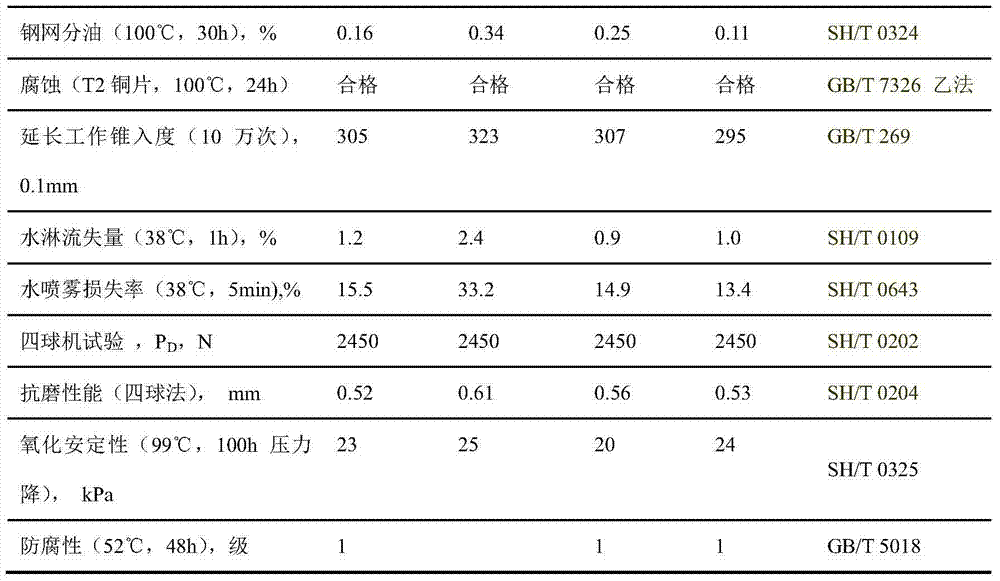

[0039] The performance index data of each embodiment lubricating grease of table 1

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com