Rice peptide production method

A production method, rice peptide technology, applied in the field of rice peptide production, can solve the problems of lower product protein purity, low yield of rice peptide, long processing cycle, etc., achieve short production cycle, high product purity, and increase added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

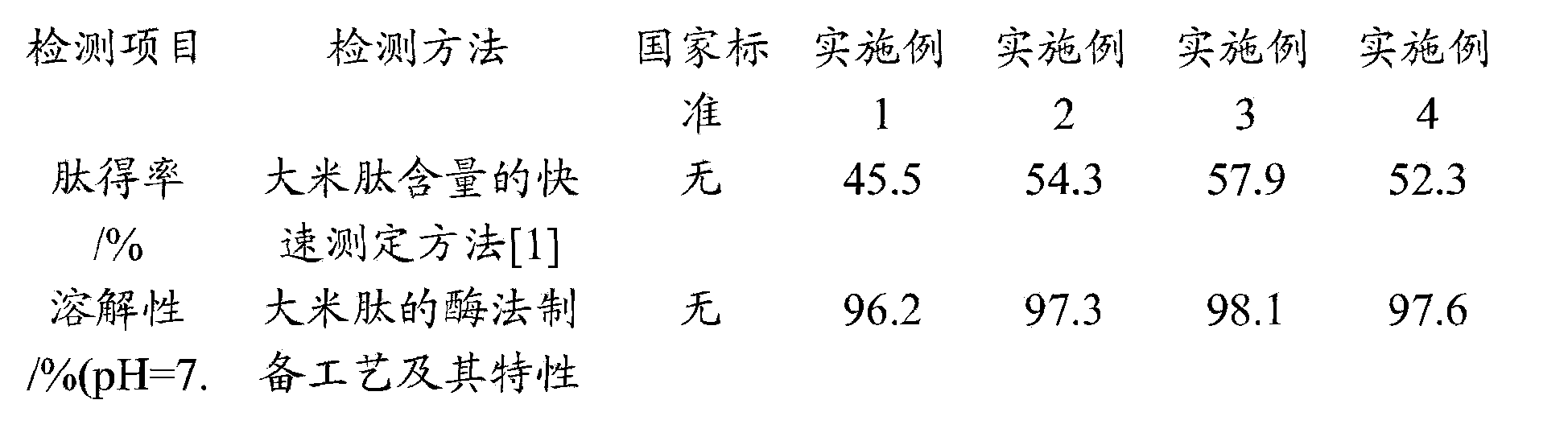

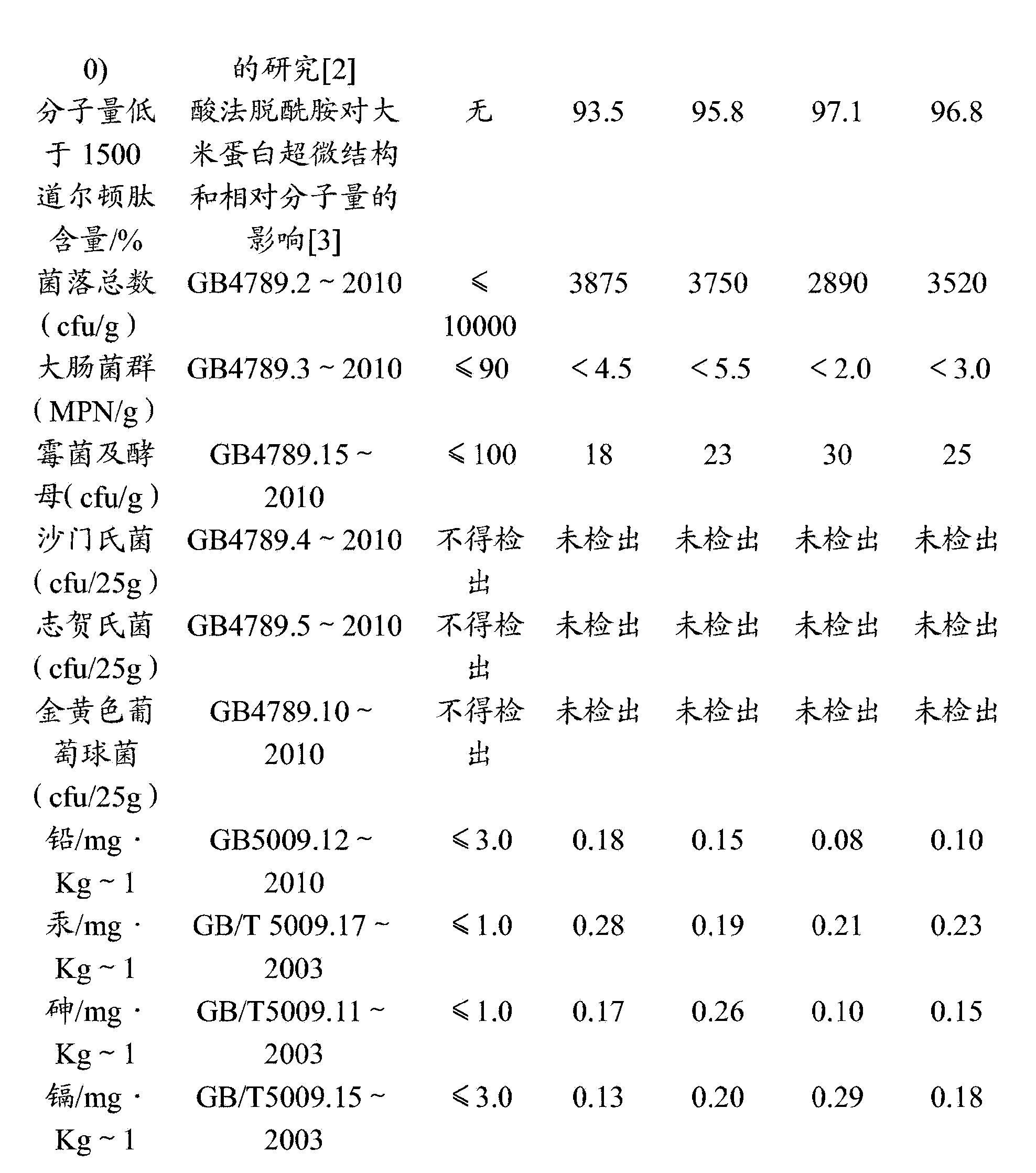

Examples

Embodiment 1

[0030] Rice peptide production method, concrete steps are as follows:

[0031] A. Weigh 5000g of 100-mesh rice protein powder and put it into the enzymolysis tank, add 25L of 2% sodium sulfite solution, fully stir the material liquid, control the temperature of the enzymolysis tank at 45°C, and continue to keep warm after the temperature of the enzymolysis tank is stable 30min. A rice protein slurry is obtained.

[0032] B, the pH of rice protein slurry is controlled at 9.0 with 1mol / L sodium hydroxide solution. Add 5g of alkaline protease for enzymolysis. During the enzymolysis process, use 1mol / L sodium hydroxide solution to control the pH of the reaction at 9.0, keep stirring for 2.5h, then stop adding alkali, and continue stirring for 0.5h.

[0033] C, adjust the pH of the rice protein slurry through alkaline protease treatment to 7.2 with 1mol / L hydrochloric acid solution, add neutral protease 25g, compound flavor protease 25g and papain 100g to carry out enzymolysis at...

Embodiment 2

[0038] Rice peptide production method, concrete steps are as follows:

[0039] A. Weigh 5000g of 300-mesh rice protein powder and put it into the enzymolysis tank, add 50L of 1% sodium sulfite solution, fully stir the material liquid, control the temperature of the enzymolysis tank at 65°C, and continue to keep warm after the temperature of the enzymolysis tank is stable 75min. A rice protein slurry is obtained.

[0040] B. After the temperature of the feed liquid is stabilized, the pH of the rice protein slurry is controlled at 8.5 with 1mol / L sodium hydroxide solution. Add 125g of alkaline protease for enzymolysis. During the enzymolysis process, use 1mol / L sodium hydroxide solution to control the pH of the reaction at 8.5, keep stirring for 0.5h, then stop adding alkali, and continue stirring for 2.5h.

[0041] C. Use 1mol / L hydrochloric acid solution to adjust the pH of the rice protein slurry treated with alkaline protease to 7.0. At the same time, add 5g of neutral pro...

Embodiment 3

[0046] Rice peptide production method, concrete steps are as follows:

[0047] A. Weigh 5000g of 600-mesh rice protein powder and put it into the enzymolysis tank, add 75L of 1% sodium sulfite solution, fully stir the material liquid, control the temperature of the enzymolysis tank at 75°C, and continue to keep warm after the temperature of the enzymolysis tank is stable 120min. A rice protein slurry is obtained.

[0048] B. After the temperature of the feed liquid is stabilized, the pH of the rice protein slurry is controlled at 7.5 with 2mol / L sodium hydroxide solution. Add 150g of alkaline protease for enzymolysis. During the enzymolysis process, use 2mol / L sodium hydroxide solution to control the pH of the reaction at 8.5, keep stirring for 1.5h, then stop adding alkali, and continue stirring for 1.5h.

[0049] C. Use 2mol / L hydrochloric acid solution to adjust the pH of the rice protein slurry treated with alkaline protease to 6.5, and add 100g of neutral protease, 100g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com