Preparation method of graphene

A graphene and graphite technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, inorganic chemistry, etc., can solve the problems of reducing agent environmental pollution, affecting the quality of graphene, and introducing impurities into products, etc., to achieve The preparation process is simple, conducive to wide application, and the effect of high purity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of method for preparing graphene that the embodiment of the present invention provides comprises the following steps:

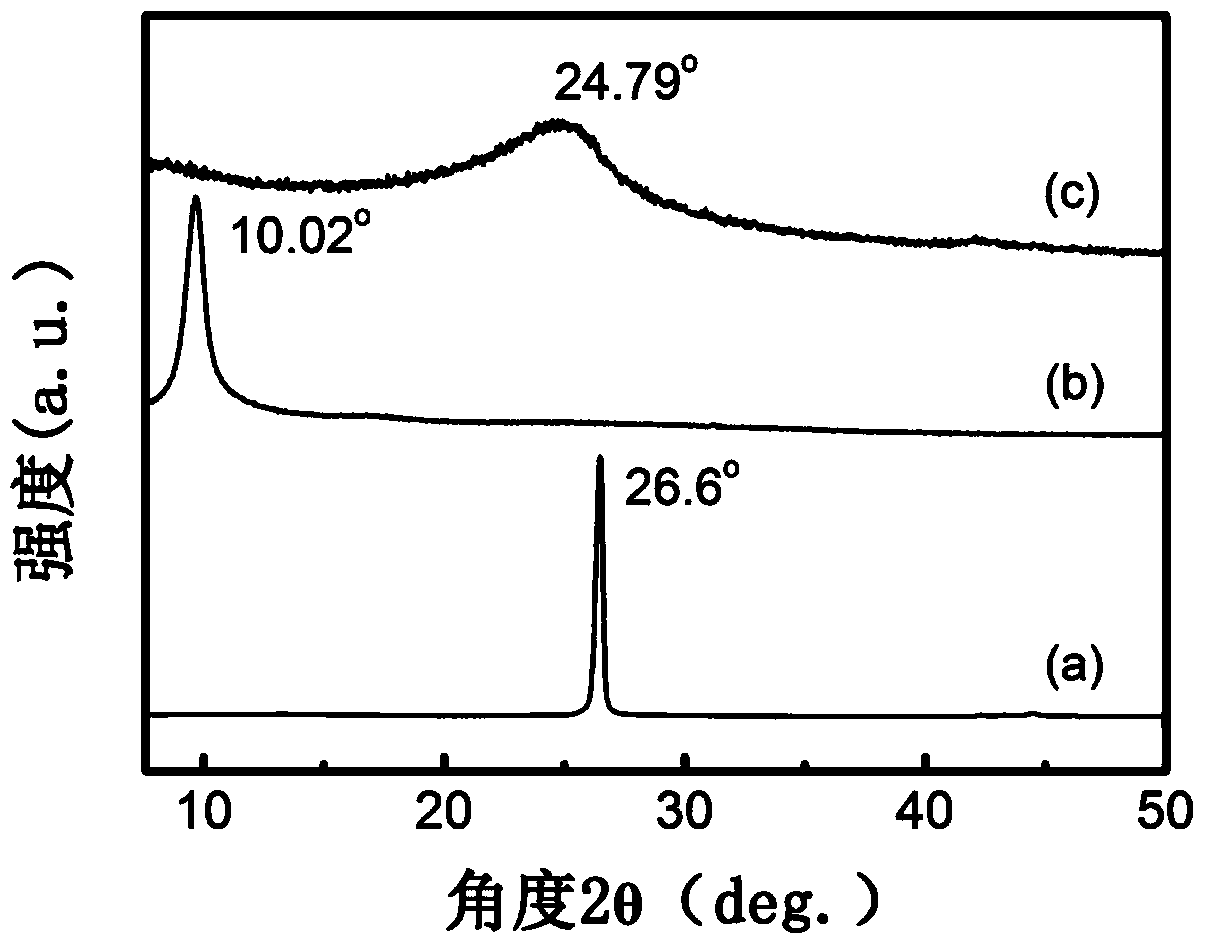

[0029] S20, the preparation step of graphene oxide: add graphite oxide powder into deionized water, obtain the graphene oxide dispersion liquid of graphene oxide in deionized water by ultrasonic vibration; Wherein, the consumption ratio of graphite oxide powder and deionized water is 0.1 mg: 1ml ~ 1mg: 1ml, that is, add 0.1mg ~ 1mg graphite oxide powder per milliliter of deionized water.

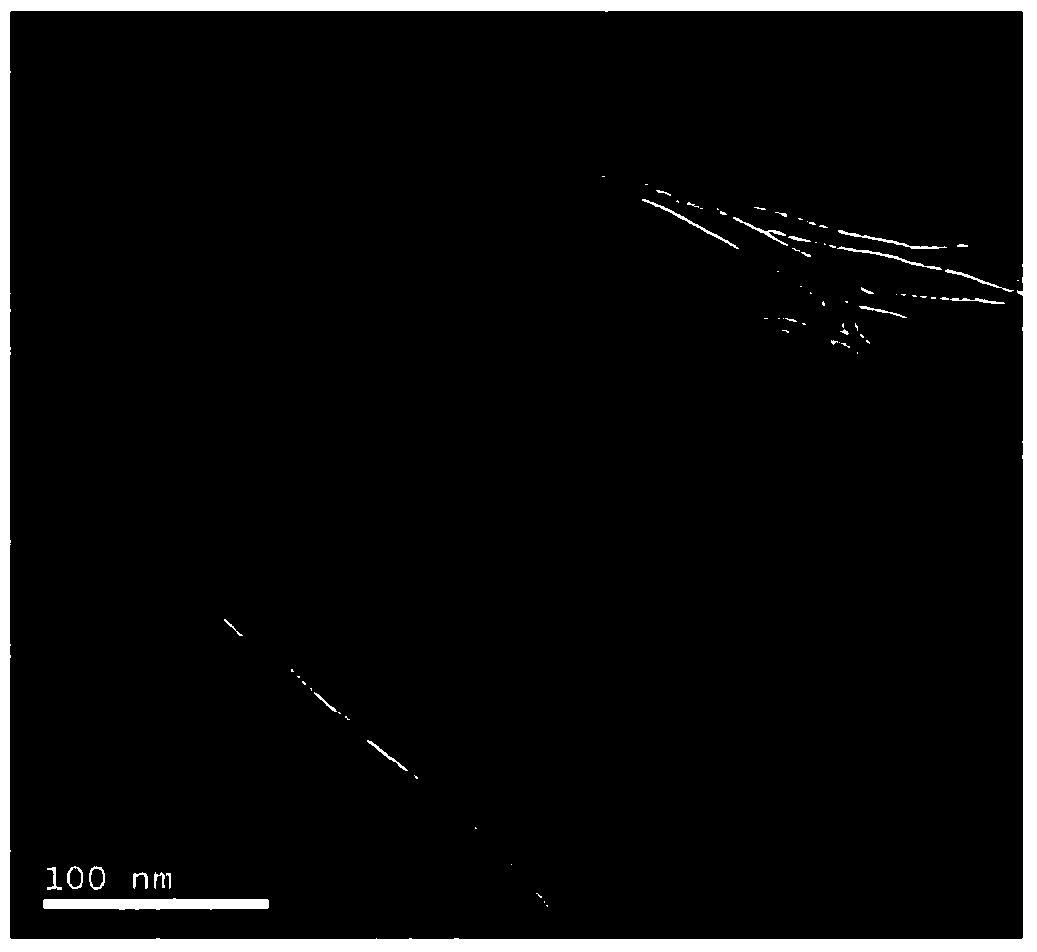

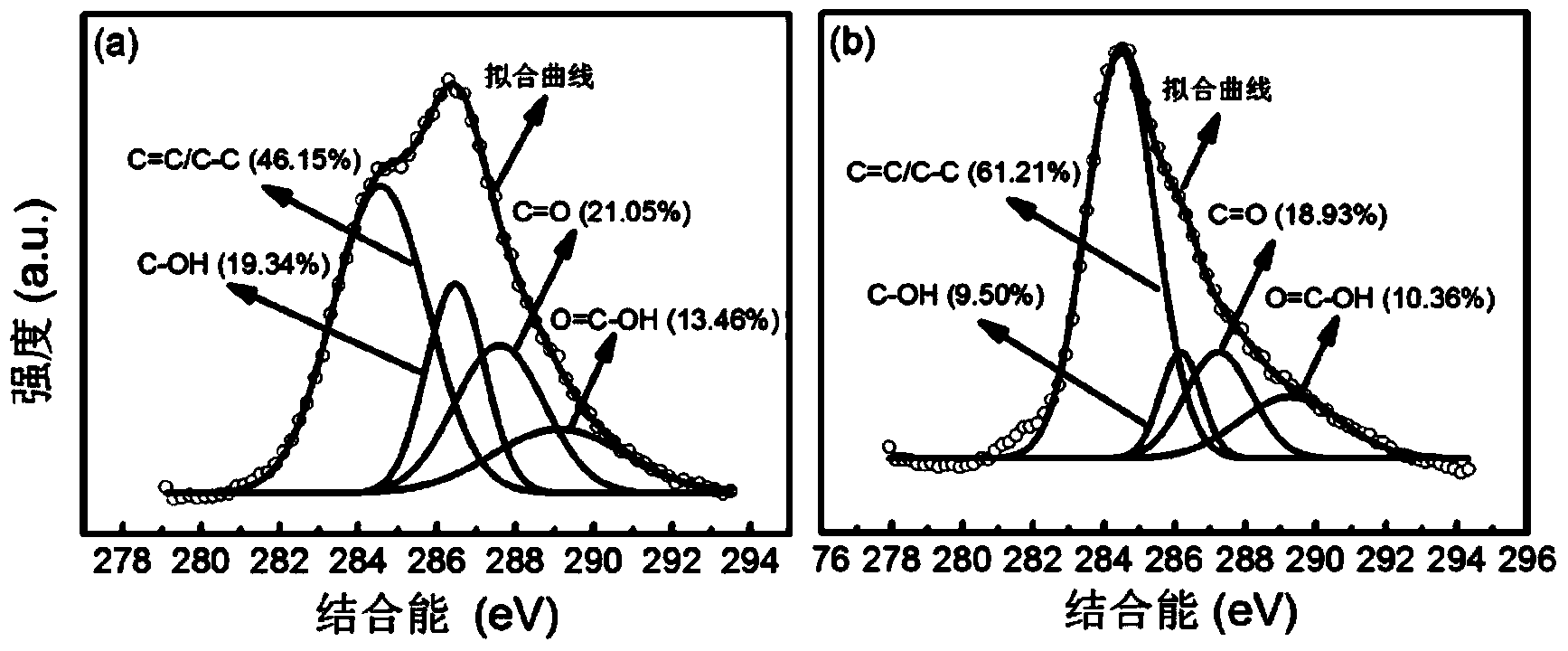

[0030] S30, the preparation step of graphene: add caffeic acid powder to graphene oxide dispersion liquid, wherein, the mass ratio of caffeic acid powder and graphite oxide powder is 10:1~50:1; The obtained mixture oil bath is heated to 85 °C to 95 °C with continuous stirring, obtain a graphene solution through a reduction reaction for 2 hours to 24 hours, then filter through a microporous membrane to collect the product, and finally vacuum dry the product to ...

Embodiment 2

[0043] A kind of method for preparing graphene that the preferred embodiment of the present invention provides comprises the following steps:

[0044] S10, the preparation step of graphite oxide.

[0045]Specifically, natural graphite and the concentrated sulfuric acid that mass concentration is 98% are uniformly mixed at room temperature, wherein the consumption ratio of concentrated sulfuric acid and natural graphite is 25ml:1g, promptly adds 25 milliliters of concentrated sulfuric acid for every 1 gram of natural graphite; Add potassium permanganate in batches under the bath temperature and continue to stir, wherein the ice bath temperature refers to 0°C, and the mass ratio of potassium permanganate and natural graphite is 3.5:1 to 5.5:1, preferably 3.5:1; The obtained mixture was heated to 35°C in a water bath and stirred evenly, and after 2 hours of reaction, deionized water was added, wherein the ratio of deionized water to natural graphite was 100ml:1g, that is, 100 mil...

Embodiment 3

[0057] Mix natural graphite and concentrated sulfuric acid with a mass concentration of 98% evenly at room temperature, wherein the dosage ratio of concentrated sulfuric acid and natural graphite is 25ml:1g; add high manganese in 6 times within 2 hours at ice bath temperature (0°C) Potassium permanganate and continuous stirring, the time interval between every two additions is 20min, the mass ratio of potassium permanganate and natural graphite is 3.5:1. The resulting mixture was heated to 35°C in a water bath and stirred by a magnetic stirrer. Add deionized water after reacting for 2 hours, wherein the consumption ratio of deionized water and natural graphite is 100ml:1g, then add the hydrogen peroxide that mass concentration is 30%, wherein the consumption ratio of hydrogen peroxide and natural graphite is 8ml:1g, will obtain The solution was washed repeatedly with hydrochloric acid and deionized water. During the cleaning process, first use dilute hydrochloric acid with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com