Method for recycling waste mercury catalyst

A waste mercury catalyst and catalyst technology, used in chemical recovery, chemical instruments and methods, mercury halide and other directions, can solve the problems of high corrosion of equipment, high operating cost, mercury catalyst poisoning, etc., and achieve high recovery efficiency and improve desorption. Efficiency, ensuring the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

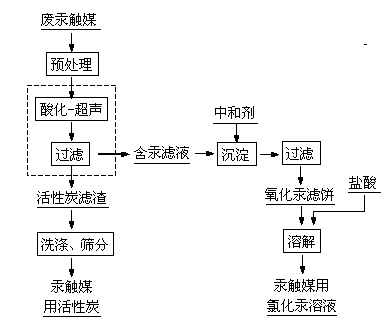

Image

Examples

Embodiment 1

[0017] Weigh 200g of waste mercury catalyst, which contains 3.4% mercury chloride, add it to 800ml of water, heat to 70°C, carry out hot-melt pretreatment under stirring, adjust the pH value to 1, and at 70°C, after ultrasonic treatment for 60min Taking advantage of the situation to filter, the mercuric chloride, phosphorus, and sulfur impurities detached from the surface of the activated carbon can be separated from the activated carbon in time. After filtering, the obtained activated carbon can be used in the preparation of mercuric chloride catalyst after being washed and sieved. Heat the obtained mercury-containing filtrate to 50°C, add sodium carbonate solution, adjust the pH to 6, and react for 30 minutes, so that the mercury ions in the solution are completely converted into mercuric oxide precipitates, while the mercury catalyst poisons phosphorus and sulfur remain in the solution. After filtering, the mercuric oxide filter cake is obtained, which is dissolved with hyd...

Embodiment 2

[0019] Weigh 200g of waste mercury catalyst, which contains 3.4% mercury chloride, add it to 900ml of water, heat to 75°C, carry out hot-melt pretreatment under stirring, adjust the pH value to 2, and at 75°C, through 50min ultrasonic treatment, in Filtration in the ultrasonic field enables the mercuric chloride, phosphorus, and sulfur impurities detached from the surface of the activated carbon to be separated from the activated carbon in time. After filtering, the obtained activated carbon can be reused in the preparation of mercuric chloride catalyst after being washed and sieved. Heat the obtained mercury-containing filtrate to 60°C, add solid sodium carbonate, adjust the pH to 7, and react for 40 minutes, so that the mercury ions in the solution are completely converted into mercuric oxide precipitates, while the mercury catalyst poison phosphorus and sulfur remain in the solution. After filtration, the mercuric oxide filter cake is obtained, which is dissolved with hydro...

Embodiment 3

[0021] Weigh 200g of waste mercury catalyst, which contains 3.9% mercury chloride, add it to 1000ml of water, heat to 80°C, carry out hot-melt pretreatment under stirring, adjust the pH value to 3, and at 80°C, after ultrasonic treatment for 40min Taking advantage of the situation to filter, the mercuric chloride, phosphorus, and sulfur impurities detached from the surface of the activated carbon can be separated from the activated carbon in time. After filtering, the obtained activated carbon can be reused in the preparation of mercuric chloride catalyst after being washed and sieved. Heat the obtained mercury-containing filtrate to 70°C, add solid sodium bicarbonate, adjust the pH to 8, and react for 50 minutes, so that the mercury ions in the solution are completely converted into mercuric oxide precipitates, while the poisonous phosphorus and sulfur in the mercury catalyst remain in the solution . After filtration, the mercuric oxide filter cake is obtained, which is diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com