A kind of preparation method of cacu3ti4o12 film doped with zirconium

A thin film and mixed liquid technology, applied in liquid chemical plating, ceramics, coatings, etc., can solve problems such as difficult to control film stoichiometric ratio, uncontrollable hydrolysis and condensation reactions, expensive equipment and vacuum conditions, etc. It is not easy to achieve Oxygen loss, low cost, and strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

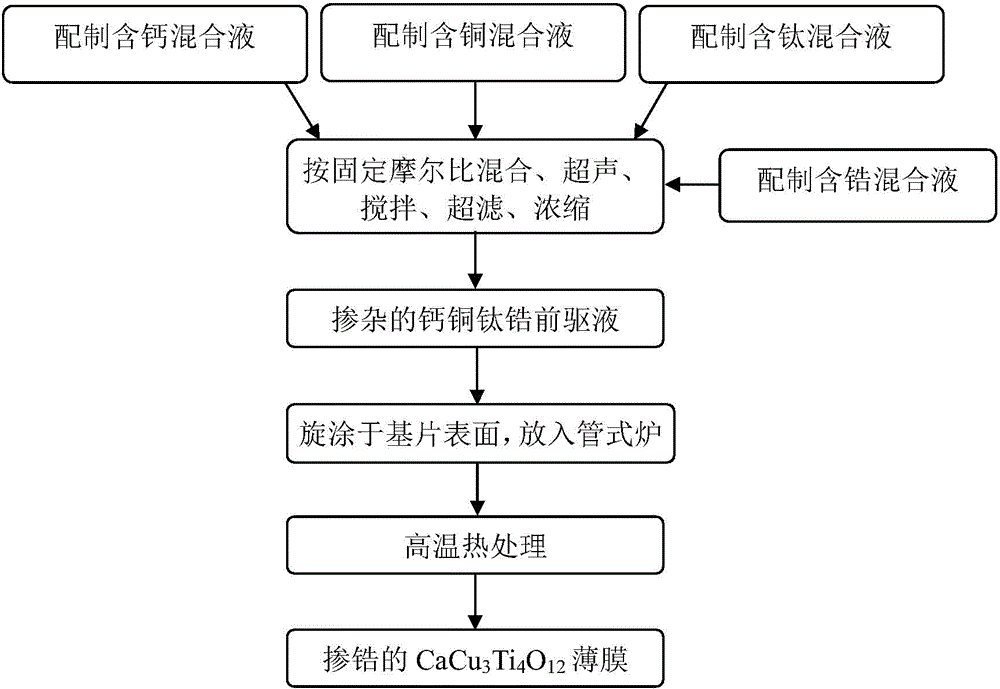

[0025] Embodiment 1: a kind of CaCu doped with zirconium 3 Ti 4 o 12 The preparation method of thin film, comprises the steps:

[0026] Step 1: Prepare a mixed solution containing calcium-copper-titanium. Specifically include the following steps:

[0027] (1) At room temperature, add 2g of inorganic Ca(NO 3 ) 2 salt to obtain a mixed solution A, add 2g of water-soluble polymer polyethyleneimine (PEI) with amino groups and 2g of stabilizing complexing agent ethylenediaminetetraacetic acid (EDTA) to solution A, ultrasonic and stir until The solution was clear and transparent, and mixed solution B was obtained. Use an ultrafiltration device to filter out free ions in solution B, and evaporate and concentrate to obtain calcium-containing mixed solution X with a concentration of 103.03 mmol / L;

[0028] (2) Add 2g Cu(NO 3 ) 2 To obtain mixed solution C, add 2gPEI macromolecule and 2gEDTA to solution C and ultrasonically stir to obtain mixed solution D, filter mixed solution...

Embodiment 2

[0041] The difference between this example and Example 1 is that in step 3, 0.48mL of zirconium-containing mixed solution I is taken, and added to the calcium-copper-titanium mixed solution obtained in step 1, fully mixed, stirred, and ultrasonically obtained to obtain a 10% molar ratio doped Zr 4+ calcium copper titanium zirconium precursor.

[0042] Below to the CaCu that embodiment 2 obtains 3 Ti 4 o 12 Analysis of the structure and properties of the film:

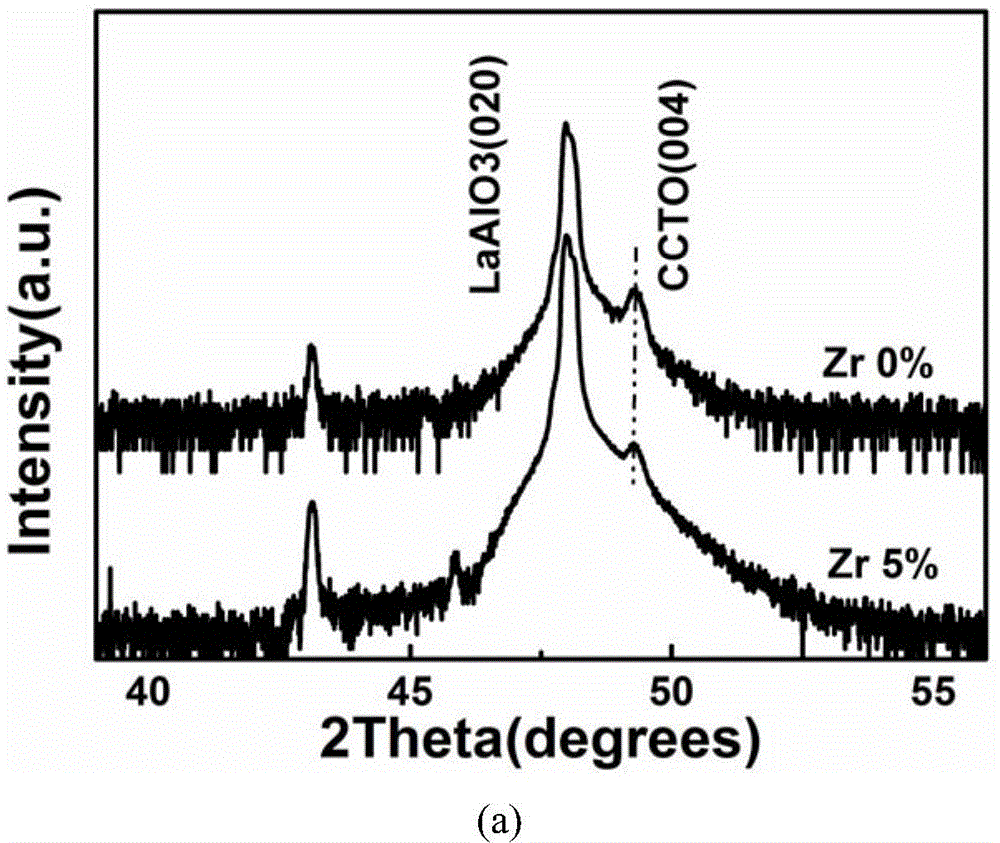

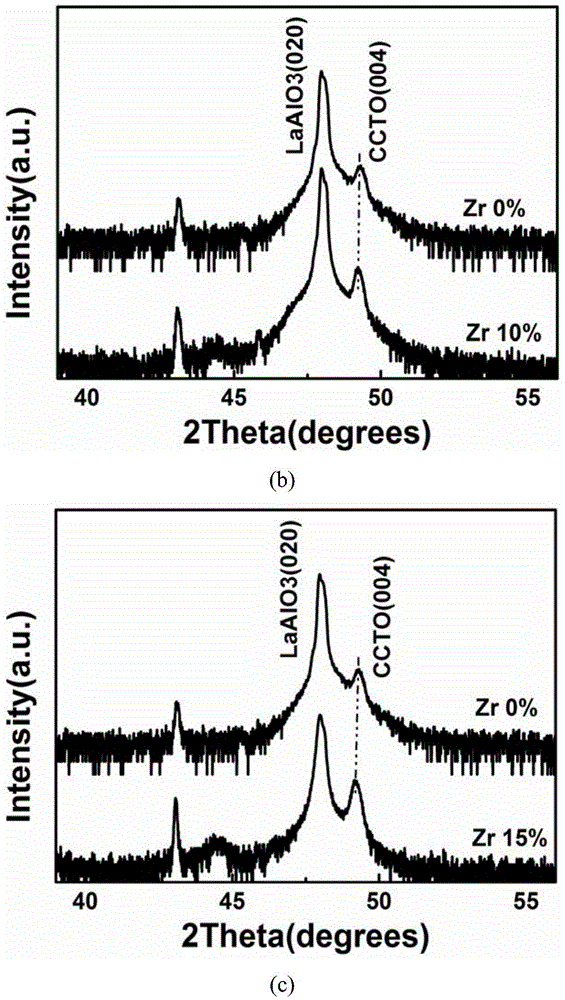

[0043] figure 2 (b) CaCu obtained for Example 2 3 Ti 4 o 12 The X-ray diffraction (XRD) θ-2θ scanning pattern of the film, which is shown on the single crystal substrate LaAlO 3 Successfully prepared CaCu doped with zirconium ions 3 Ti 4 o 12 Thin film, CaCu doped with zirconium ions 3 Ti 4 o 12 The CCTO (004) peak of the film compared with 0% doped CaCu 3 Ti 4 o 12 The film phase shifts to the left, indicating that the doped CaCu 3 Ti 4 o 12 The film unit cell becomes larger.

[0044] Figure 4 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com