Eucommia ulmoides packaged noodle and manufacturing technique thereof

A technology of dried noodles and Eucommia, which is applied in the technical field of adding Eucommia leaves to make dried noodles, which can solve the problems of not obvious blood pressure lowering effect, and achieve the effects of simple operation, improved elasticity, and prolonged storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the making of Eucommia vermicelli

Embodiment 1

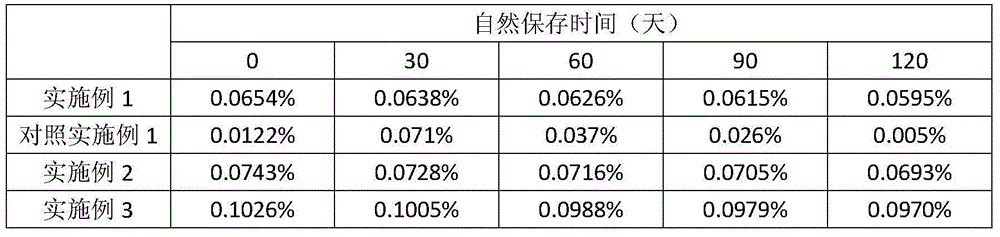

[0035] Add 100kg of dry flour to 400kg of room temperature water to dissolve into flour milk; keep warm at 70-85°C for 10-15min, and stir thoroughly during the process to form a viscous and transparent flour paste, vacuum degass and cool to 40°C for later use; Tea drum degreening machine for 2-3 minutes, dried at 40-50°C and crushed to about 40 meshes; added 12 kg of crushed Eucommia leaves to the flour paste, stirred at 25-35°C for 6 minutes, and then added 380 kg of dry leaves Flour, so that the water content reaches about 45%, transfer to the dough mixer and keep the speed at 14r / min-16r / min, after stirring, let it stand to form a dough; after mixing the dough, carry out vacuum degassing treatment for 30min again; ripen, press slices, cut into strips, quickly dried at 48°C for 40 minutes, cut off, and packaged; the products were tested for active ingredients. Chlorogenic acid detection conditions: chromatographic column is KromasiLC 18 (250×4.6mm, 5μm); detection wavelengt...

Embodiment 2

[0036] Embodiment 2: the making of Eucommia vermicelli

[0037] Add 200kg of dry flour to 900kg of room temperature water to dissolve into flour milk; keep warm at 70-85°C for 10-15min, and stir thoroughly during this time to form a viscous and transparent flour paste, vacuum degass and cool to 40°C for later use; Tea drum degreening machine for 2-3 minutes, dried at 40-50°C and crushed to about 40 meshes; 30kg of crushed Eucommia leaves were added to the flour paste, stirred at 25-35°C for 6 minutes, and then 800kg of dry leaves were added Flour, so that the water content reaches about 40%, transfer to the dough mixer and keep the speed at 14r / min-16r / min, after stirring, let it stand to form a dough; after mixing the dough, carry out vacuum degassing treatment for 30min again; ripen, press slices, cut into strips, quickly dried at 48°C for 40 minutes, cut off, and packaged; the active ingredients of the products were tested, and the content of chlorogenic acid was found to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com