Relaxation ferroelectric material Sr4CaBiTi3Nb7O30 and preparation method thereof

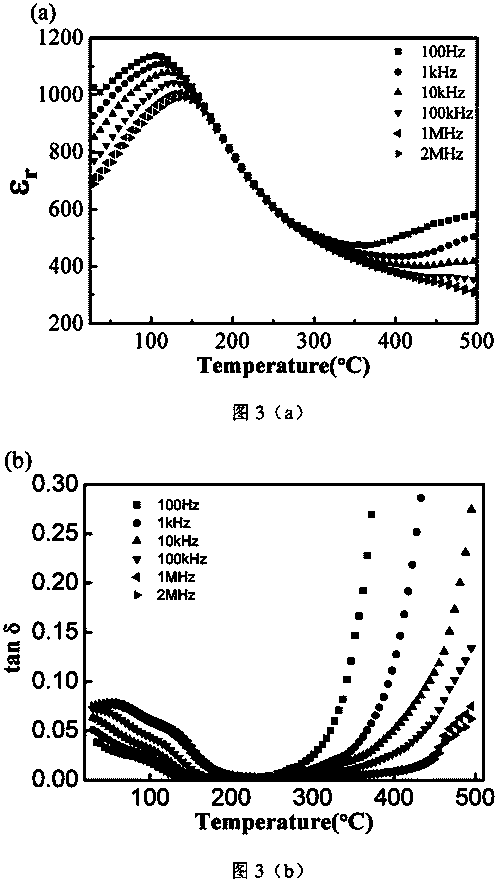

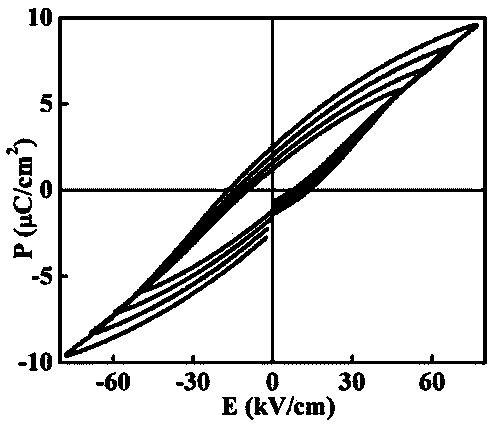

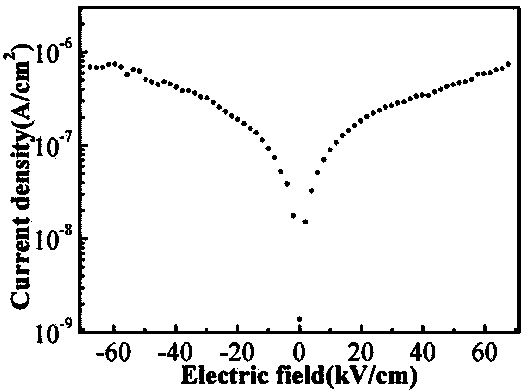

A ferroelectric material and relaxation technology, which is applied in the preparation field of the relaxor ferroelectric material Sr4CaBiTi3Nb7O30, achieves the effect of simple preparation process, low leakage current, and strong room temperature ferroelectricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention use the traditional solid phase method to prepare the ferroelectric ceramic sample Sr through pre-sintering and sintering. 4 CaBiTi 3 Nb 7 o 30 , including the following steps:

[0019] The first step, weigh the solid powder SrCO 3 , CaCO3, Bi 2 o 3 、TiO 2 , Nb 2 o 5 , and their stoichiometric amounts are 0.12, 0.03, 0.015, 0.09, and 0.105 mol, respectively. After thorough mixing, add absolute ethanol and ball mill for 20-30 hours.

[0020] In the second step, the resulting mixed solution is added to absolute ethanol and completely sucked out from the ball mill jar into a beaker. Put the beaker containing the mixed solution into an oven, and bake at 110° C. for 10 hours to obtain a solid mixture. The solid mixture obtained above was put into a mortar and ground for 2 hours to obtain a solid powder mixture. The resulting mixture was transferred to an alumina crucible, and placed in a programmed furnace, pre-fired a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Leakage current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com