Preparation method for infrared heat-light modulator adopting sandwich composite structure

A thermo-optical modulator and composite structure technology, applied in the field of optoelectronics, can solve the problems of increasing manufacturing cost and complexity, and achieve the effects of broad market application prospects, fast phase transition speed and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, this embodiment cannot be used to limit the present invention, and all similar methods and similar changes of the present invention should be included in the protection scope of the present invention.

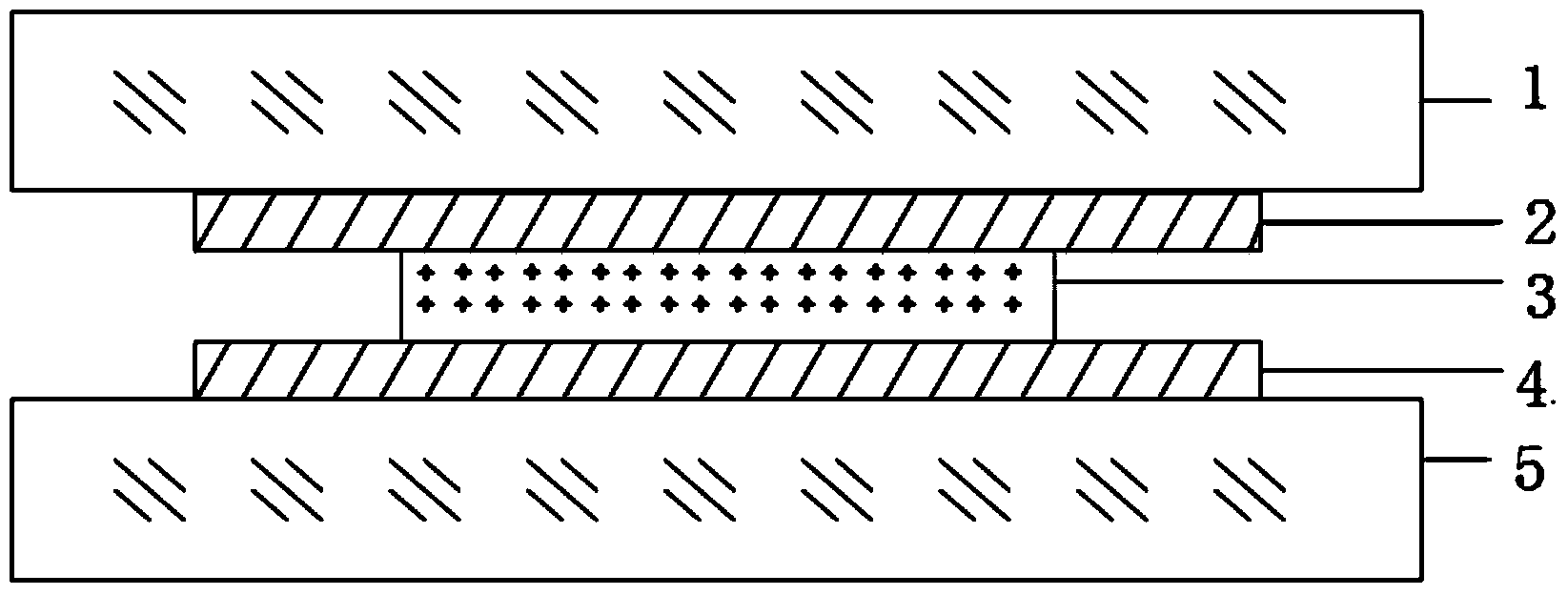

[0016] figure 1 It is a structural schematic diagram of the sandwich composite structure infrared thermo-optic modulator of the present invention. Wherein 1 is one of the upper sapphire substrate, sulfur-gallium silver substrate or zinc sulfide substrate, 2 is the upper FTO transparent conductive film layer, 3 is the nano vanadium dioxide film layer, 4 is the lower FTO transparent conductive film layer, 5 is one of the lower layer sapphire substrate, sulfur gallium silver substrate or zinc sulfide substrate.

[0017] The preparation method of the sandwich composite structure infrared light modulator in the present invention, its steps are as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com