Preparation method of fluorine-containing copolymer fibers

A technology of copolymer and fiber, which is applied in the field of preparation of fluorine-containing copolymer fiber, and achieves the effects of simple process, convenient industrial implementation and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Ethylene-chlorotrifluoroethylene copolymer resin (provided by Solvay, USA 500LC product, the same below) placed in a vacuum drying oven at 70°C, dried for 16 hours and then used for later use; the dried resin was sent to a two-zone twin-screw spinning machine, and the spinning temperatures of the first and second twin-screw zones were respectively 265°C and 270°C, the screw speed is 3.0r / min, and the melt is obtained; the melt is extruded through the spinneret assembly at 270°C under the condition of extrusion speed of 0.4m / min, and the melt extruded thing;

[0022] The molten extruded product passed through a 1.0 m long air bath and was wound at a winding speed of 8.5 m / min to obtain ethylene-chlorotrifluoroethylene copolymer fibers.

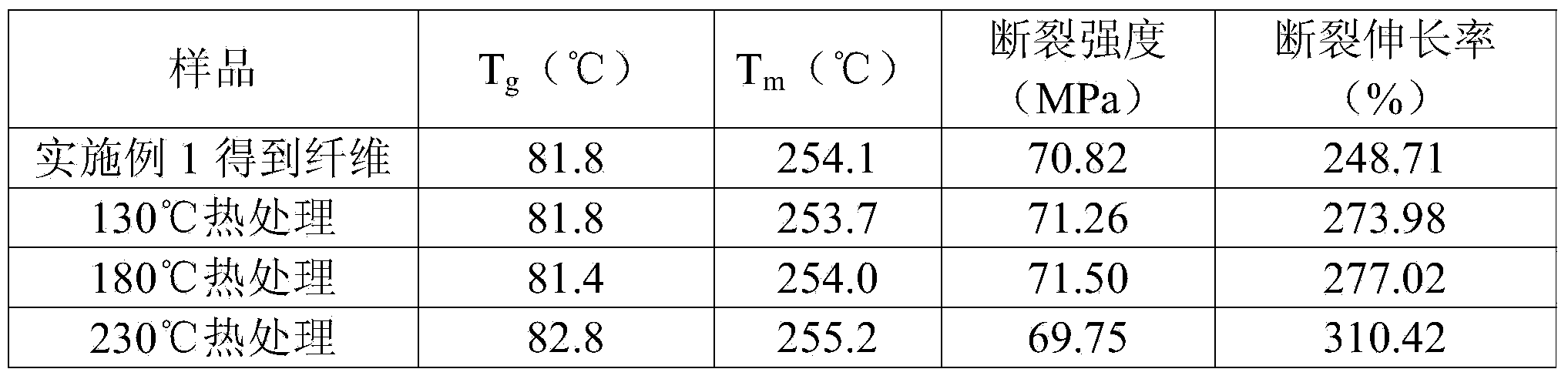

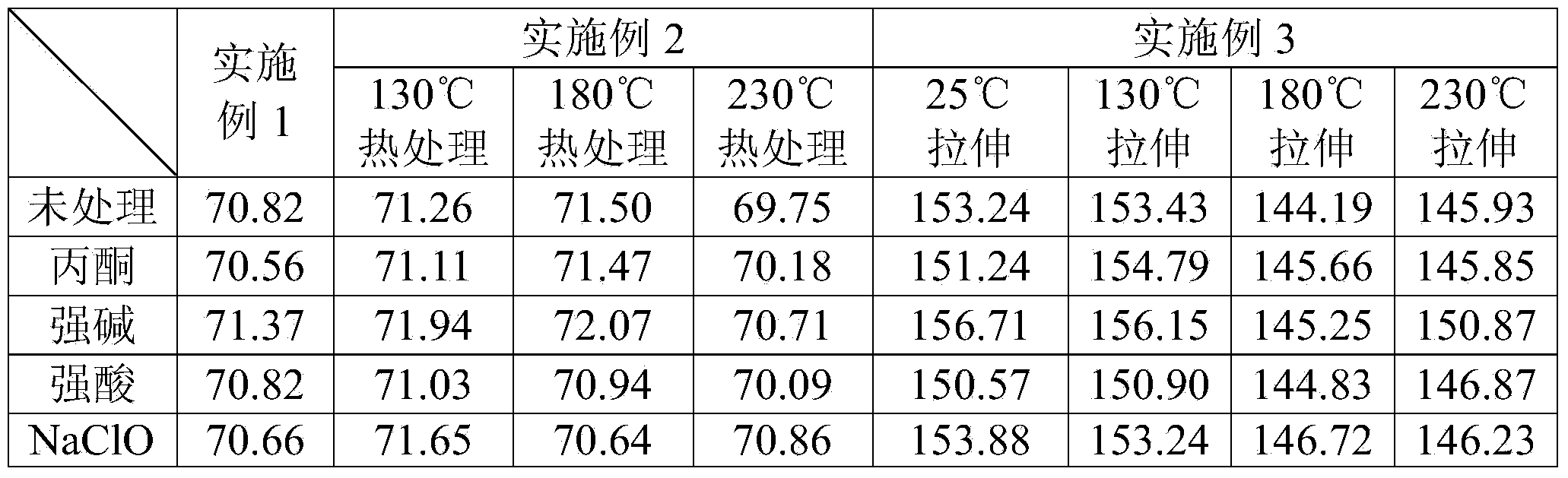

[0023] In this embodiment, the diameter of the spinneret assembly is 1 mm, the average diameter of the obtained fibers is 214.966 μm, and the average density is 1.885 g / cm 3 , the average linear density is 684.055dTex; the glass trans...

Embodiment 2

[0025] Ethylene-chlorotrifluoroethylene copolymer resin (provided by Solvay, USA 500LC product) placed in a vacuum drying oven at 70°C, dried for 15 hours and then used for later use; the dried resin was sent to a two-zone twin-screw spinning machine, where the spinning temperatures of the first and second twin-screw zones were 265°C, 270°C, the screw speed is 3.0r / min, and the melt is obtained; the melt is extruded through the spinneret assembly at 270°C under the condition of extrusion speed of 0.4m / min, and the molten extrudate is obtained;

[0026] The molten extruded product passed through a 1.0 m long air bath and was wound at a winding speed of 8.5 m / min to obtain ethylene-chlorotrifluoroethylene copolymer fibers.

[0027] The prepared ethylene-chlorotrifluoroethylene copolymer fibers were relaxed and heat-treated in oil baths at three different temperatures of 130°C, 180°C, and 230°C for 30 minutes, taken out, washed, and dried to obtain heat-treated ethylene-trifluor...

Embodiment 3

[0032] Ethylene-chlorotrifluoroethylene copolymer resin (provided by Solvay, USA 500LC product, the same below) placed in a vacuum drying oven at 70°C, dried for 15 hours and then used for later use; the dried resin was sent to a two-zone twin-screw spinning machine, and the spinning temperatures of the first and second twin-screw zones were respectively 265°C and 270°C, the screw speed is 3.0r / min, and the melt is obtained; the melt is extruded through the spinneret assembly at 270°C under the condition of extrusion speed of 0.4m / min, and the melt extruded thing;

[0033] The molten extruded product passed through a 1.0 m long air bath and was wound at a winding speed of 8.5 m / min to obtain ethylene-chlorotrifluoroethylene copolymer fibers.

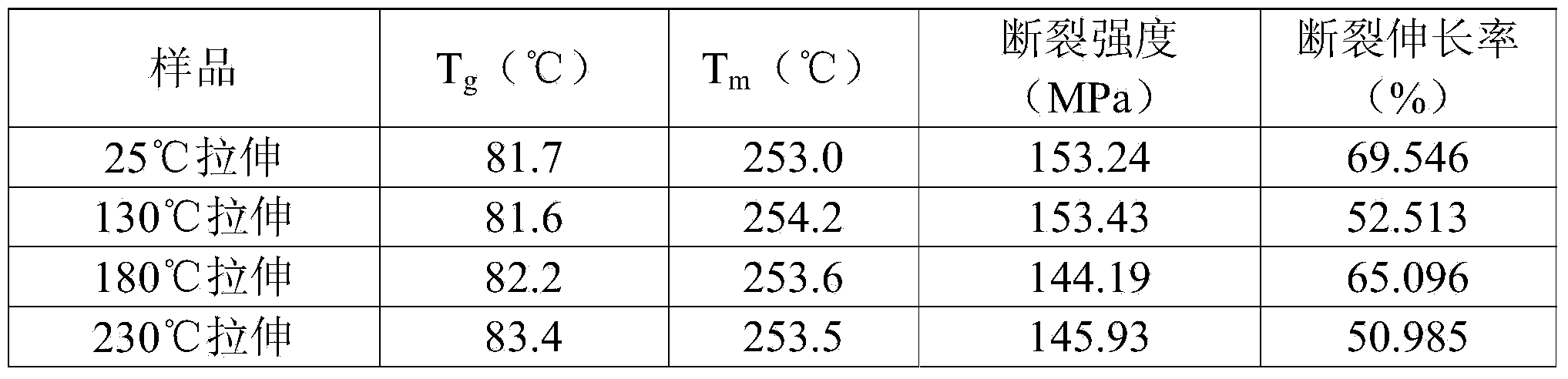

[0034] The prepared ethylene-chlorotrifluoroethylene copolymer fibers were stretched twice in oil baths at 25°C, 130°C, 180°C, and 230°C respectively, and fixed to length and heat-set for 20 to 40 minutes, then taken out, washed, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com