A flexible tooling control system for assisting laser cutting of aerospace titanium plates

A control system, laser cutting technology, applied in the direction of general control system, control/regulation system, program control, etc., can solve problems such as difficult to realize flexible manufacturing of thin-walled parts, and achieve the effect of powerful function, simple device, and suppression of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific examples of implementation.

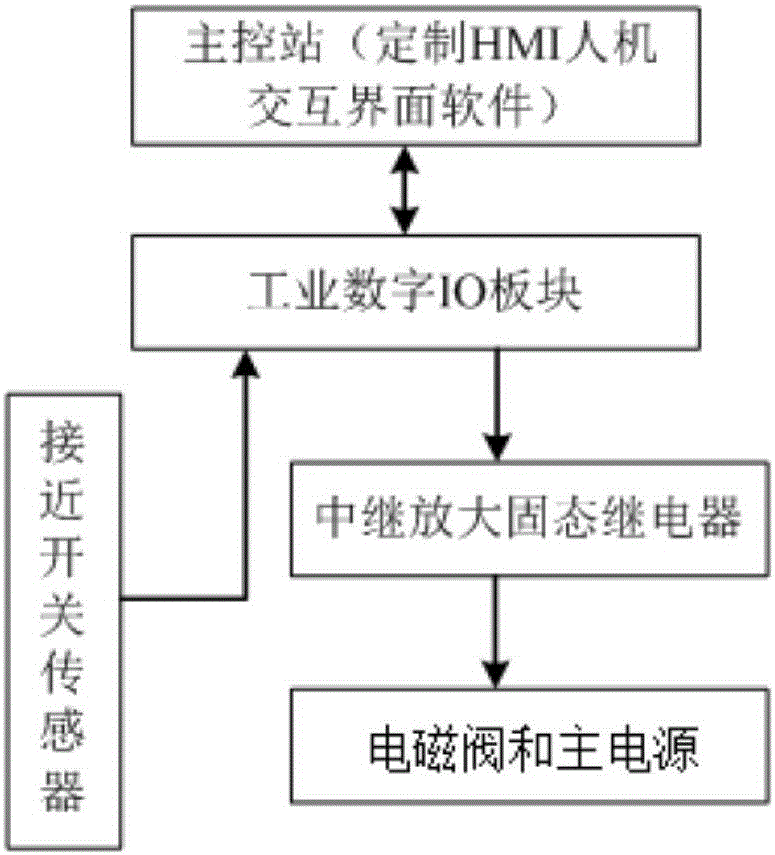

[0032] figure 1 It is a frame diagram of the electrical system of the flexible tooling control system used to assist the laser cutting of aerospace titanium plates in the present invention. The system includes a main control station, an industrial digital IO board, a proximity switch sensor, a relay amplifying solid state relay, a solenoid valve and a main power supply ; Among them, the main control station adopts Advantech industrial control machine, which controls the whole system in real time through customized software, and monitors and displays according to the status. At the same time, it can be directly connected to the virtual machine system to display the status of the device synchronously; PCI-1756 digital input and output board, including 32-way input and 32-way output, realizes the status monitoring of the solenoid va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com