Degradable wound repair material and preparation method thereof

A wound repair and matrix material technology, applied in the fields of biomedical materials and biomedical engineering, can solve the problems of loss of mechanical support structure, difficulty in loading antimicrobial ingredients, wound healing factors, wound susceptibility to infection, etc., and achieve good anti-infection performance , promote the effect of wound repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

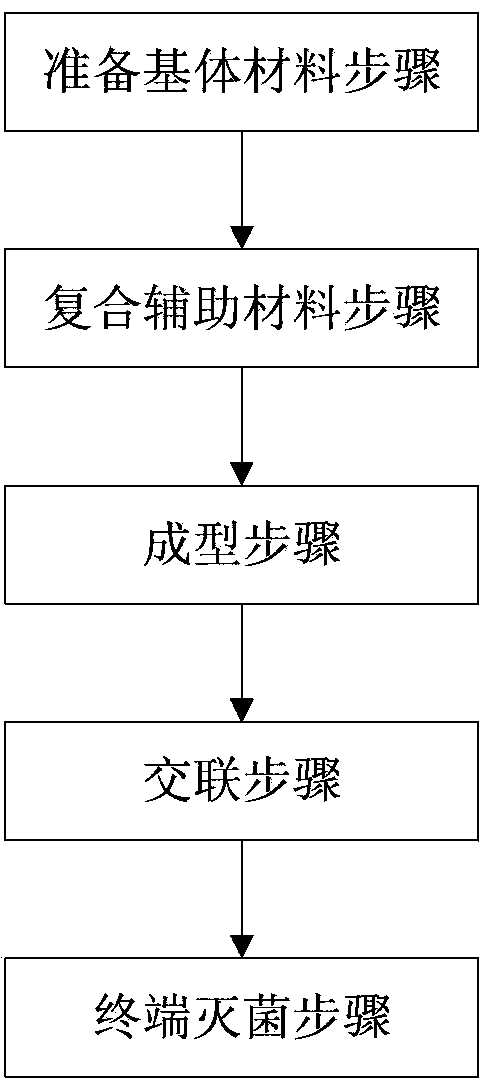

[0038] like figure 1 As shown, the preparation method of the degradable wound repair material of the present invention includes the main steps described in detail below.

[0039] 1. Steps to prepare the base material:

[0040] 1. Preparation of solution: Select one or more of the above-mentioned raw materials and prepare solutions respectively. The solution concentration (mass fraction concentration) and solvent are as follows: Collagen: 0.01% to 10%, acid (0.05% by mass) %~10% acetic acid or hydrochloric acid, etc.) or pure water; silk fibroin: 0.02%~10%, pure water; polysaccharide: 0.001%~15%, acid (0.001%~10% acetic acid or hydrochloric acid, etc.) or pure water.

[0041]2. Compounding: take the protein component as the first component, add the second component or the third component or other component solutions of the complex into the solution of the first component in turn under the condition of stirring, and use The method of direct pouring or gradual addition, afte...

Embodiment 1

[0090] Prepare 1% type I collagen solution with 3% acetic acid aqueous solution as solvent, and prepare 0.001% chitosan solution with 0.001% acetic acid aqueous solution as solvent. Then, take 4 parts by mass of type I collagen solution, and add 1 part by mass of chitosan solution while stirring at a speed of 500 rpm, and the addition speed is 2ml / min, and continue to stir after adding to form a uniform composite solution. The mass ratio of collagen and chitosan in the obtained complex liquid is 4000:1.

[0091] The VEGF-loaded PBS solution is added to the compound liquid, stirred and mixed evenly, so that in the formed compound, the mass ratio of the active factor to the dry weight of the compound is 1 / 100. The resulting composite solution was defoamed for 20 minutes under 20 Pa vacuum condition.

[0092] Weigh the defoamed compound solution, pour it into a mold, freeze at -150°C for 5 minutes, and then freeze-dry it in a freeze dryer (the temperature is first -65°C and then...

Embodiment 2

[0095] Prepare 10% type III collagen solution with 0.05% acetic acid aqueous solution as solvent, and prepare 0.02% silk fibroin solution with pure aqueous solution as solvent. Then, take 6 parts by mass of type III collagen solution and add 1 part by mass of silk fibroin solution while stirring at 1000 rpm at a speed of 0.5ml / min. After the addition is completed, continue to stir to form a uniform composite solution. The mass ratio of collagen and silk fibroin in the obtained composite solution is 3000:1.

[0096] Add 5 volumes of pure water dispersion (2 g / L) of gentamicin-loaded PLGA microspheres into the compound solution and stir to mix evenly. The resulting composite solution was defoamed for 10 minutes under a vacuum condition of 10 Pa.

[0097] Weigh the defoamed composite solution, cast it in the mold, and then air-dry it at room temperature (30°C). The air-dried film is continuously pressed at a static pressure of 5 MPa for 168 hours to obtain a pressed film.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com