Polycarbonate/acrylonitrile-acrylic ester-styrene (PC/ASA) alloy and preparation method thereof

An acrylate and polycarbonate technology, applied in the field of polymer composite materials, can solve problems such as poor weather resistance, and achieve the effects of convenient operation and control, excellent dimensional stability, and excellent balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

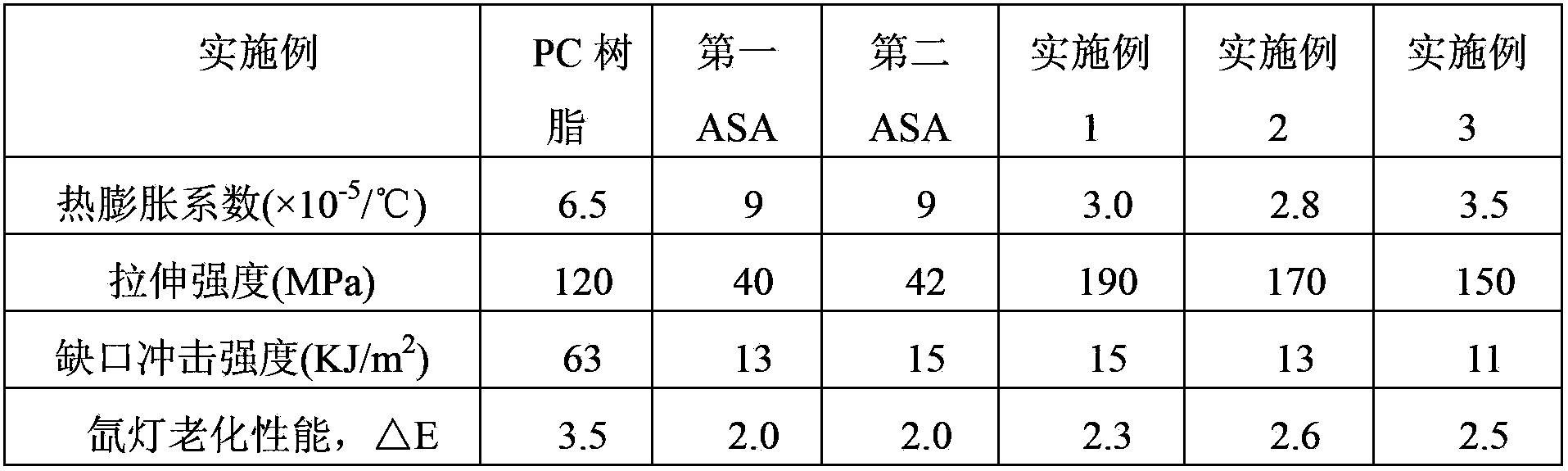

Examples

Embodiment 1

[0043] (1) Preparation of ASA masterbatch: 25 parts of the first ASA resin, 10 parts of basalt fiber, 0.2 parts of antioxidant tris(2,4-di-tert-butylphenyl) phosphite were fully mixed in a high-speed mixer for 5 minutes , using twin-screw extrusion melt kneading and blending method, the twin-screw extruder temperature from the feed port to the extrusion die is 170 ° C, 200 ° C, 210 ° C, 220 ° C, 230 ° C, the host speed is 20 Hz , make fiber-filled ASA masterbatch, make fiber-filled ASA masterbatch, standby;

[0044] (2) 35.2 parts of ASA masterbatch prepared in step (1) were bonded with 40 parts of polycarbonate PC (weight average molecular weight 20000g / mol), 25 parts of second ASA resin, 0.1 part of compatibilizer maleic anhydride Branch AS, 0.6 parts of light stabilizer 2-hydroxyl-4-n-octyloxybenzophenone are fully mixed, adopt the melting and kneading blending method of screw extruding, from feeding port to extrusion die head temperature is respectively 200°C, 220°C, 230°...

Embodiment 2

[0046] (1) Preparation of ASA masterbatch: 15 parts of the first ASA resin, 4 parts of carbon fiber, 1 antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester After fully mixing in the high-speed mixer for 3 minutes, the twin-screw extrusion melt kneading and blending method is adopted. The temperature of the twin-screw extruder from the feed port to the extrusion die is 190°C, 220°C, 240°C, 240°C, 250°C, the speed of the host machine is 40 Hz, and the fiber-filled ASA masterbatch is made, and the fiber-filled ASA masterbatch is prepared for use;

[0047] (2) 20 parts of ASA masterbatch prepared in step (1) were bonded with 85 parts of polycarbonate PC (weight average molecular weight: 30000g / mol), 15 parts of second ASA resin, 0.5 parts of compatibilizer maleic anhydride ABS, 0.4 parts of light stabilizer N,N'-bis(2,2,2,6-tetramethyl-4-piperidinyl)-1,6-hexamethylenediamine are fully mixed, and extruded by screw The melting kneading and b...

Embodiment 3

[0049] (1) Preparation of ASA masterbatch: 5 parts of the first ASA resin, 7 parts of glass fiber, 0.5 parts of antioxidant β-(4-hydroxy-3,5-di-tert-butylphenyl) propanoic acid n-octadecyl After the alcohol ester is fully mixed in the high-speed mixer for 4 minutes, the twin-screw extrusion melt kneading and blending method is adopted. The temperature of the twin-screw extruder from the feed port to the extrusion die is 180 ° C, 190 ° C, 230 ° C, 230 ° C ℃, 240 ℃, the host speed is 30 Hz, make fiber-filled ASA masterbatch, make fiber-filled ASA masterbatch, spare;

[0050] (2) Combine 12.5 parts of ASA masterbatch prepared in step (1) with 60 parts of polycarbonate PC (weight average molecular weight 40000g / mol), 5 parts of second ASA resin, 0.3 parts of compatibilizer maleic anhydride Branched styrene, 0.2 parts of light stabilizer bis-2,2,6,6-tetramethylpiperidinyl sebacate are fully mixed, and the melting kneading blending method of screw extrusion is adopted, from the feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com