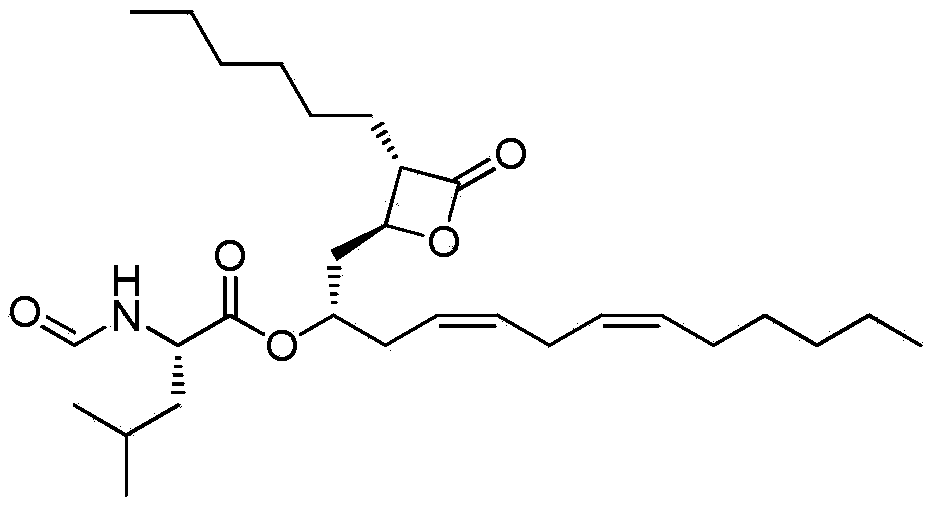

Composition for fermentation process of lipstatin

A technology of composition and solution, which is applied in the field of medicine and chemical industry, can solve the problem of low fermentation level, and achieve the effect of easy availability of raw materials and suitable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 100mL of sunflower oil, put it in a 500mL beaker, stir and heat to 70°C, under constant temperature stirring, gradually add 1mol / L sodium hydroxide solution for saponification until the pH of the solution is 10.5, stop Add sodium hydroxide solution dropwise and keep warm for half an hour, cool down to 10°C, add 100mL petroleum ether, stir, let stand, filter, wash the filter cake once with 100mL petroleum ether, collect the filter cake and put it in a 500mL beaker, add 100mL water, Under stirring, add 20% hydrochloric acid solution dropwise until the pH is 2.5, let stand to separate layers, separate the water layer, wash the oil layer with water at 30°C until neutral, collect the oil layer to obtain the composition. Gas chromatography analysis results: stearic acid 2.2%, oleic acid 17.8%, linoleic acid 74.3%, palmitic acid 5.5%, other components 0.2%.

[0026] Adopt the method described in the inventor's existing patent CN102268466B to carry out slant cultivation, ...

Embodiment 2

[0028] Weigh 1L of sunflower oil, put it in a 5L beaker, stir and heat to 70°C, under constant temperature and constant speed stirring, gradually add 1mol / L sodium hydroxide solution for saponification until the pH of the solution is 11 , stop adding sodium hydroxide solution and keep it warm for half an hour, cool down to 10°C, add 1L petroleum ether to the above mixed solution, stir, let it stand, filter, wash the filter cake once with 1L petroleum ether, collect the filter cake and place it in 5L Add 1L of water into the beaker, under stirring, dropwise add 20% hydrochloric acid solution until the pH is 2.1, let stand to separate the layers, separate the water layer, wash the oil layer with 50°C water until neutral, collect the oil layer to obtain the composition. Gas chromatography analysis results: stearic acid 2.3%, oleic acid 17.7%, linoleic acid 73.7%, palmitic acid 5.8%. Other ingredients 0.5%.

[0029] According to the operation of Fermentation Example 1, the slant ...

Embodiment 3

[0031] Weigh 10L of sunflower oil, put it in a 50L reaction kettle, stir and heat to 70°C, under constant temperature and constant speed stirring, gradually add 1mol / L sodium hydroxide solution for saponification until the pH of the solution is 10.8 , stop adding sodium hydroxide solution dropwise and keep it warm for half an hour, cool down to 10°C, add 10L petroleum ether to the above mixed solution, stir, let it stand, filter, wash the filter cake once with 1L petroleum ether, collect the filter cake and place Add 10L of water into a 50L reactor, stir, add 20% hydrochloric acid solution dropwise until the pH is 2.0, let stand to separate layers, separate the water layer, wash the oil layer with water at 40°C until neutral, collect the oil layer to obtain the combination thing. Gas chromatography analysis results: stearic acid 2.3%, oleic acid 17.6%, linoleic acid 73.7%, palmitic acid 5.7%. Other ingredients 0.7%.

[0032]According to the operation of Fermentation Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com