Preparation method for rare-earth-doped high-compaction ternary material

A ternary material, high-pressure compaction technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of resource shortage, decreased electrical performance cycle performance, low electrical conductivity, etc., and achieve easy realization of large-scale industrial The effect of production, discharge capacity improvement, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

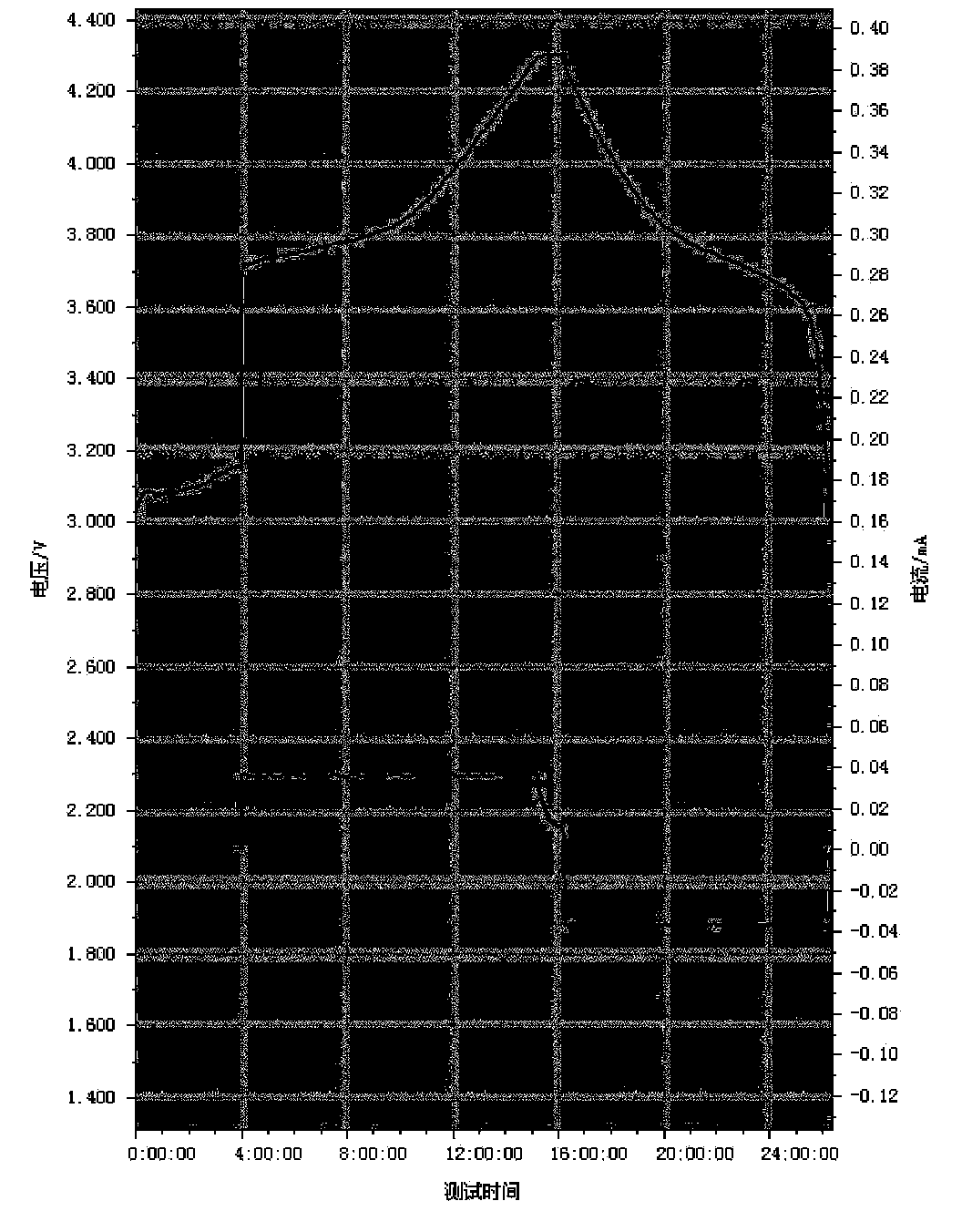

Embodiment 1

[0026] Dissolve rare earth oxides in concentrated nitric acid (standard concentrated nitric acid concentration 69.8%), then heat until the oxides are decomposed, and after cooling, use formamide to adjust the molar concentration of rare earth ions to 0.01; first add lithium carbonate powder (D50 2 microns), then according to the R / M (Ni+Co+Mn) molar ratio of 0.0095, add the solution obtained from the rare earth ion solution, then add absolute ethanol according to the solid-to-liquid ratio of 1:1, turn on the main motor of the ball mill, and run for 10 minutes According to the Li / M (Ni+Co+Mn) molar ratio of 1, add the ternary precursor (523 type, D50 is 9 microns), and ball mill for 40 minutes; the material after ball milling is dried in a vacuum dryer, and the drying time is 30 minutes. Then it is fired in a fully automatic roller kiln. The sintering temperature is set as follows: from room temperature to 650 at a rate of 1.5°C / min, then from 750°C to 900°C at a rate of 2°C, an...

Embodiment 2

[0029] Dissolve rare earth oxides in concentrated nitric acid (standard concentrated nitric acid concentration 69.8%), then heat until the oxides are decomposed, and after cooling, adjust the molar concentration of rare earth ions to 0.02 with acetamide; first add lithium carbonate powder (D50 4.25 microns), then according to the R / M (Ni+Co+Mn) molar ratio of 0.015, add the rare earth ion solution to the solution, then add absolute ethanol according to the solid-to-liquid ratio of 1:1, turn on the main motor of the ball mill, and run for 10 minutes According to the Li / M (Ni+Co+Mn) molar ratio of 1.05, add the ternary precursor (523 type, D50 is 10.43 microns), and ball mill for 90 minutes; the material after ball milling is dried in a vacuum dryer, and the drying time is 60 minutes. Then it is fired in a fully automatic roller kiln. The sintering temperature is set as follows: from room temperature to 650 at a rate of 1.5°C / min, then from 750°C to 900°C at a rate of 2°C, and ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com