Energy-saving pig feed curing system

A processing system and pig feed technology, applied in the field of pig food pretreatment equipment, can solve problems such as unsatisfactory economic benefits, low digestibility and absorption rate, unscientific preparation methods, etc., achieve valuable market application prospects, and improve digestibility Excellent absorption rate and energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

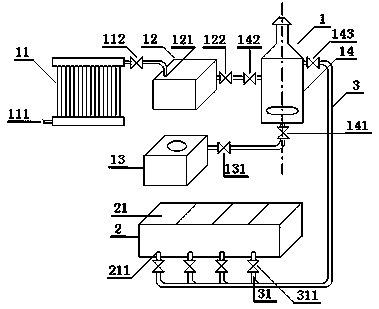

[0016] exist figure 1 Among them, the main body of the pig feed aging treatment system of the present invention includes a steam generating device 1 and a feed heating device 2, and is characterized in that: the steam generating device 1 includes a cold water inlet 111 and a hot water outlet 112. The solar water heater 11, the hot water storage tank 12 with the hot water inlet 121 and the hot water outlet joint 122, the biogas digester 13 with the biogas output joint 131 and the biogas control joint 141, the hot water inlet The steam boiler 14 that controls the switch joint 142 and the steam output control valve joint 143; the feed heating device 2 is composed of one or several cooking pools 21 that are provided with a steam inlet 211 on the side wall near the bottom; in the assembled state Next, the first hot water outlet joint 112 of the sola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com