Electroplating technology of shining tin zinc nickel alloy

A technology of nickel alloy and tin-zinc, which is applied in the field of preparation of metal porous materials with controllable through holes, can solve the problems of difficulty in increasing the concentration of plating solution and poor water solubility, and achieve the effects of low production cost, low current density and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

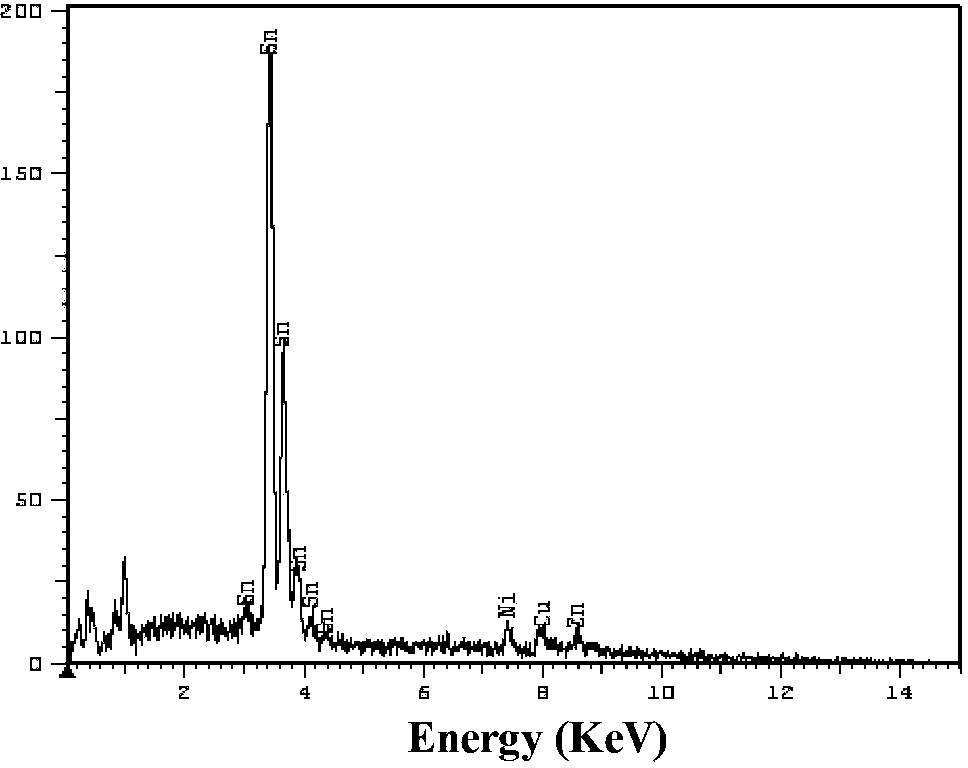

Image

Examples

Embodiment

[0051] Example: Put the carbon steel sample as the cathode, first put it in 5% NaOH, heat it to 70°C, let it stand for 3~5 minutes, put it in 5% hydrochloric acid after washing with water, and activate it for 5 minutes to completely remove the surface rust, wash it with water, and then Electroplating, electroplating anodes use nickel plate and tin-zinc plate, both of the same size, placed on both sides of the plating tank, connected to the electroplating power supply with copper wire, the power supply adopts a DC stabilized power supply. Plating solution: Potassium pyrophosphate (K 4 P 2 o 7 ) 170g / L, stannous sulfate (SnSO 4 ) 11g / L, zinc sulfate (ZnSO 4 ·7H 2 O) 25g / L, nickel sulfate (NiSO 4 ·6H 2 O) 25g / L, sodium sulfate (NaSO 4 ) 60g / L, water-soluble additive 0.6g / L, rosin (C 19 h 29 COOH) 0.3g / L, sodium dodecyl sulfate (C 12 h 25 SO 3 Na) 1.5g / L, current density 0.05A / dm 2 , the temperature is 25℃~45℃, the pH is 8.5, and the current density is 0.05A / dm 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com