Hydraulic control system for constant pressure press for timber floor

A hydraulic control system and wooden floor technology, which is applied in the field of wood machinery, can solve problems such as inability to guarantee product uniformity, immature hydraulic mechanism, and cumbersome manufacturing process, and achieve good steady-state control characteristics, low power consumption, and suppression of interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

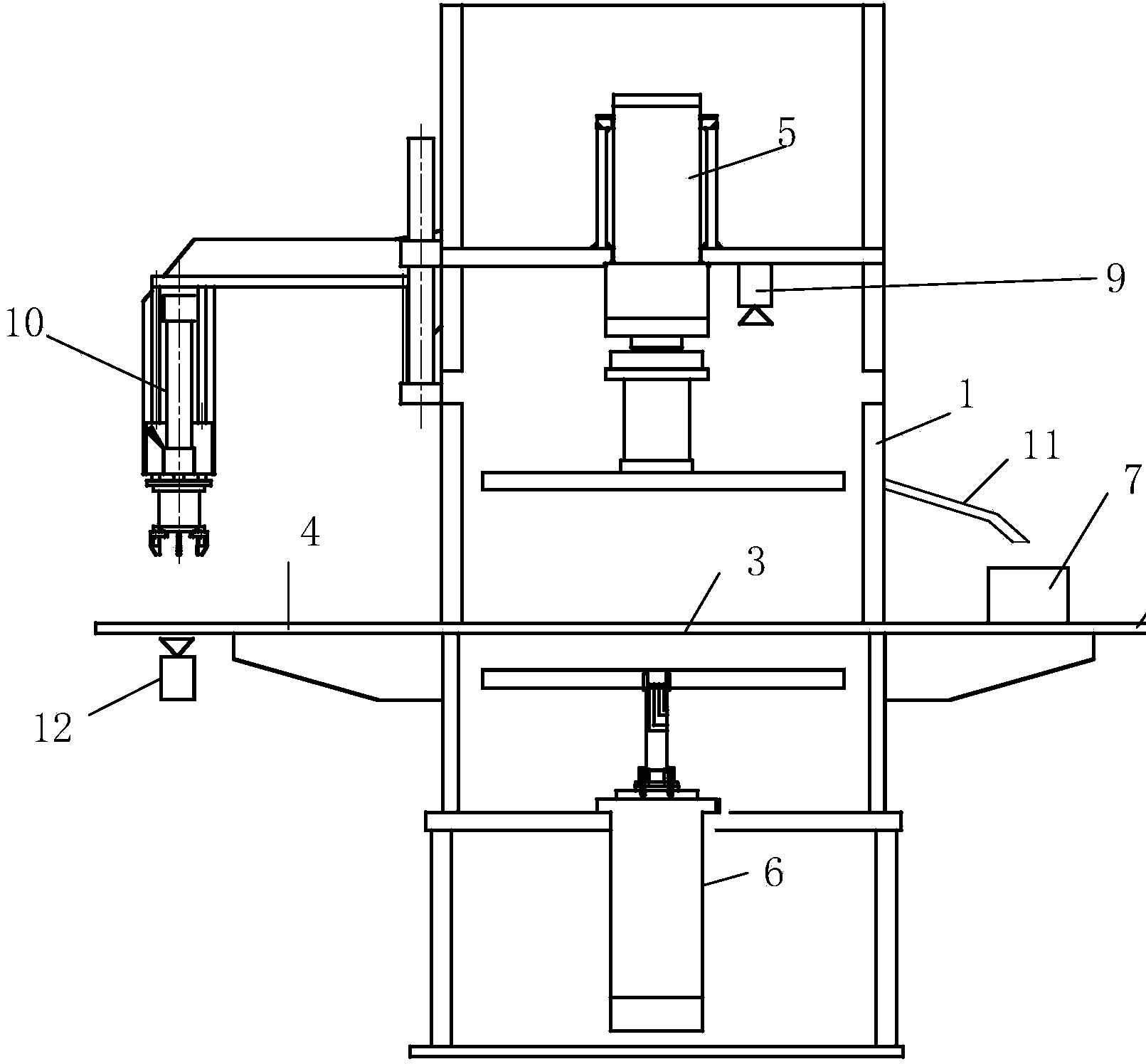

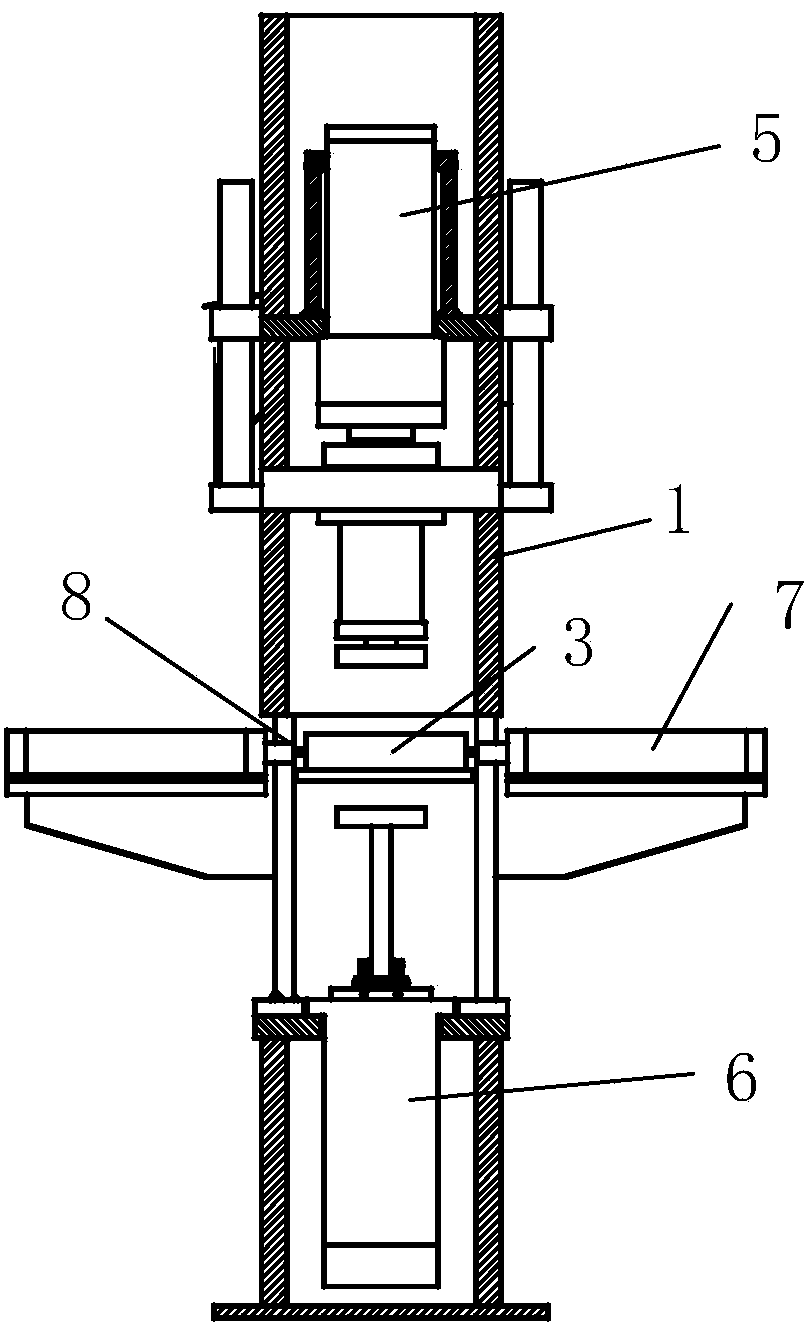

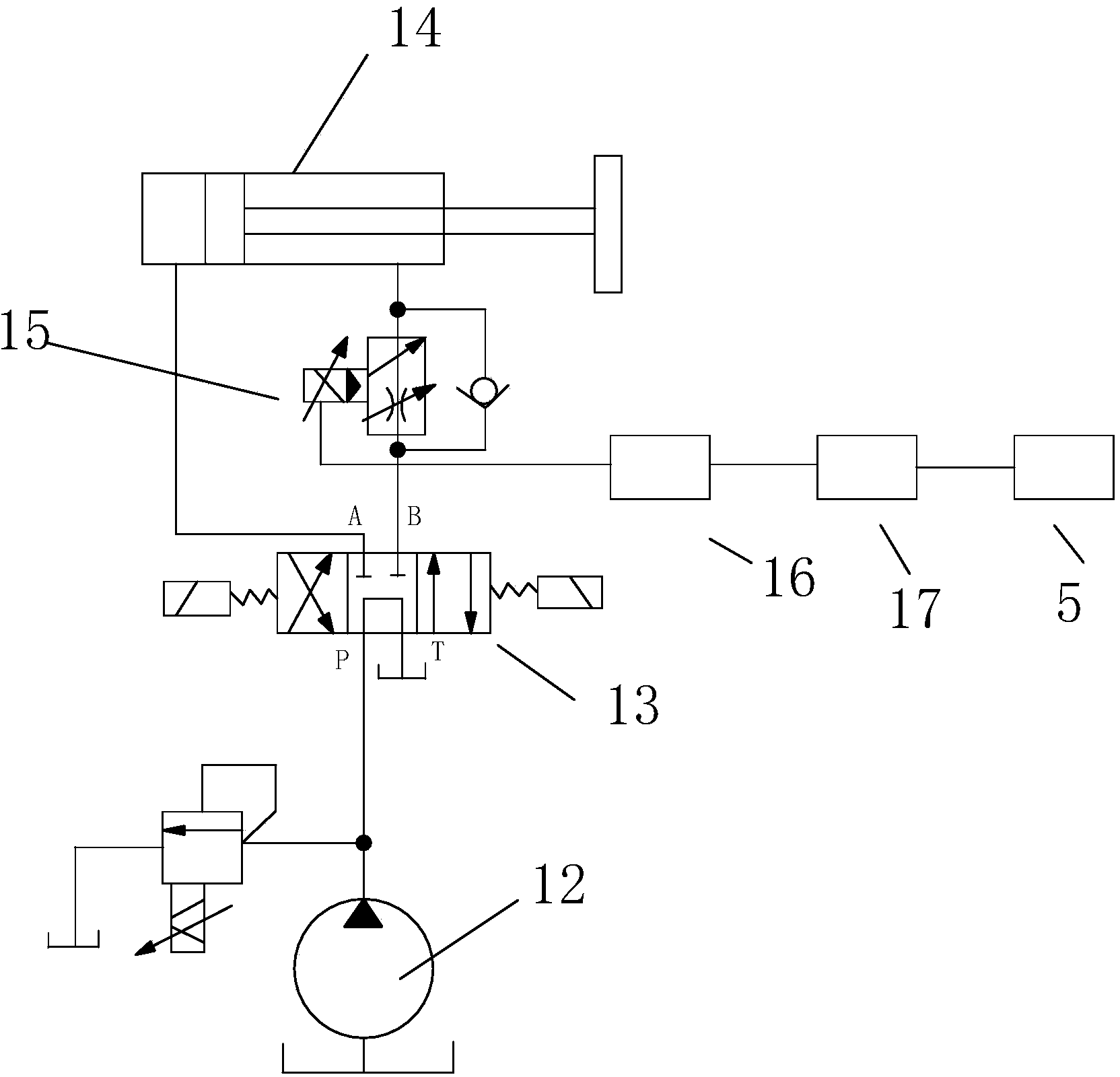

[0023] Example: a hydraulic control system for a constant pressure press on a wooden floor, such as figure 1 and figure 2 As shown, it includes a frame 1. The middle of the frame 1 is sequentially provided with a feeding conveyor belt 2, a working conveyor belt 3 and a discharging conveyor belt 4 from front to back. The feeding conveyor belt and the discharging conveyor belt are always at a fixed speed. The working conveyor belt runs at different speeds through the induction device; the top of the working conveyor belt 3 has a lower pressure cylinder 5, and the bottom of the working conveyor belt 3 has an upper pressure cylinder 6; the two sides of the working conveyor belt 3 are also A tongue-and-groove cutting cylinder 7 is provided, and the extension end of the tongue-and-groove cutting cylinder 7 is provided with a tongue-and-groove cutting tool head 8; an infrared sensing device 9 is also provided above the working conveyor belt 3, and the output end of the infrared sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com