Blumea oil composite microcapsule, preparation method thereof and multifunctional textile preparation method

A technology of composite microcapsules and mugwort leaf oil, which is applied in the direction of microcapsule preparation, microsphere preparation, textiles and papermaking, etc., can solve the problems of complex preparation process, poor finishing reaction effect of microcapsule textiles, and low utilization rate of microcapsules, etc. To achieve the effect of enriching sources, prolonging the time of drug effect, and promoting wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Preparation of mugwort leaf oil composite microcapsules

[0044] 1. Under the action of magnetic stirring, dissolve sodium alginate in water at 80°C to prepare a sodium alginate solution with a mass volume concentration of 0.5%, that is, 1 liter of water contains 5 mg of sodium alginate;

[0045] 2. Dissolve gelatin in water at 45°C to prepare a gelatin solution with a mass volume concentration of 4%, that is, 1 liter of water contains 40 mg of gelatin;

[0046] 3. Take 100mL each of the sodium alginate solution obtained in step 1 and the gelatin solution obtained in step 2 and mix them evenly, then add 0.5g of emulsifier Tween-80 and 1g of mugwort leaf oil to the mixed solution, and stir them evenly at 1500r / min The rotational speed high-speed shearing emulsification 5min, obtains mugwort leaf oil composite microcapsule emulsion, see for example figure 1 ;

[0047] 4. Keep the mugwort leaf oil composite microcapsule emulsion obtained in step 3 at 50°C, use a spray...

Embodiment 2

[0083] 1. Preparation of mugwort leaf oil composite microcapsules

[0084] 1. Under the action of magnetic stirring, dissolve sodium alginate in water at 80°C to prepare a sodium alginate solution with a mass volume concentration of 1%, that is, 1 liter of water contains 10 mg of sodium alginate;

[0085]2. Dissolve gelatin in water at 45°C to prepare a gelatin solution with a mass volume concentration of 6%, that is, 1 liter of water contains 60 mg of gelatin;

[0086] 3. Take 100mL each of the sodium alginate solution obtained in step 1 and the gelatin solution obtained in step 2 and mix well, add 1g of emulsifier Tween-80 and 2g of mugwort leaf oil to the mixed solution, stir well and then use 3000r / min Rotating speed and high-speed shear emulsification for 5 minutes to obtain the compound microcapsule emulsion of Artemisia argyi leaf oil.

[0087] 4. Keep the mugwort leaf oil composite microcapsule emulsion obtained in step 3 at 60°C, use a spray dryer to spray at an inle...

Embodiment 3

[0108] 1. Preparation of mugwort leaf oil composite microcapsules

[0109] 1. Under the action of magnetic stirring, dissolve sodium alginate in water at 80°C to prepare a sodium alginate solution with a mass volume concentration of 2%, that is, 1 liter of water contains 20 mg of sodium alginate;

[0110] 2. Dissolve gelatin in water at 45°C to prepare a gelatin solution with a mass volume concentration of 8%, that is, 1 liter of water contains 80 mg of gelatin;

[0111] 3. Take 100mL each of the sodium alginate solution obtained in step 1 and the gelatin solution obtained in step 2 and mix well, add 1g of emulsifier Tween-80 and 3g of mugwort leaf oil to the mixed solution, stir well and then use 3000r / min Rotating speed and high-speed shear emulsification for 10 minutes to obtain the mugwort leaf oil composite microcapsule emulsion.

[0112] 4. Keep the mugwort leaf oil composite microcapsule emulsion obtained in step 3 at 60°C, and use a spray dryer to spray at an inlet te...

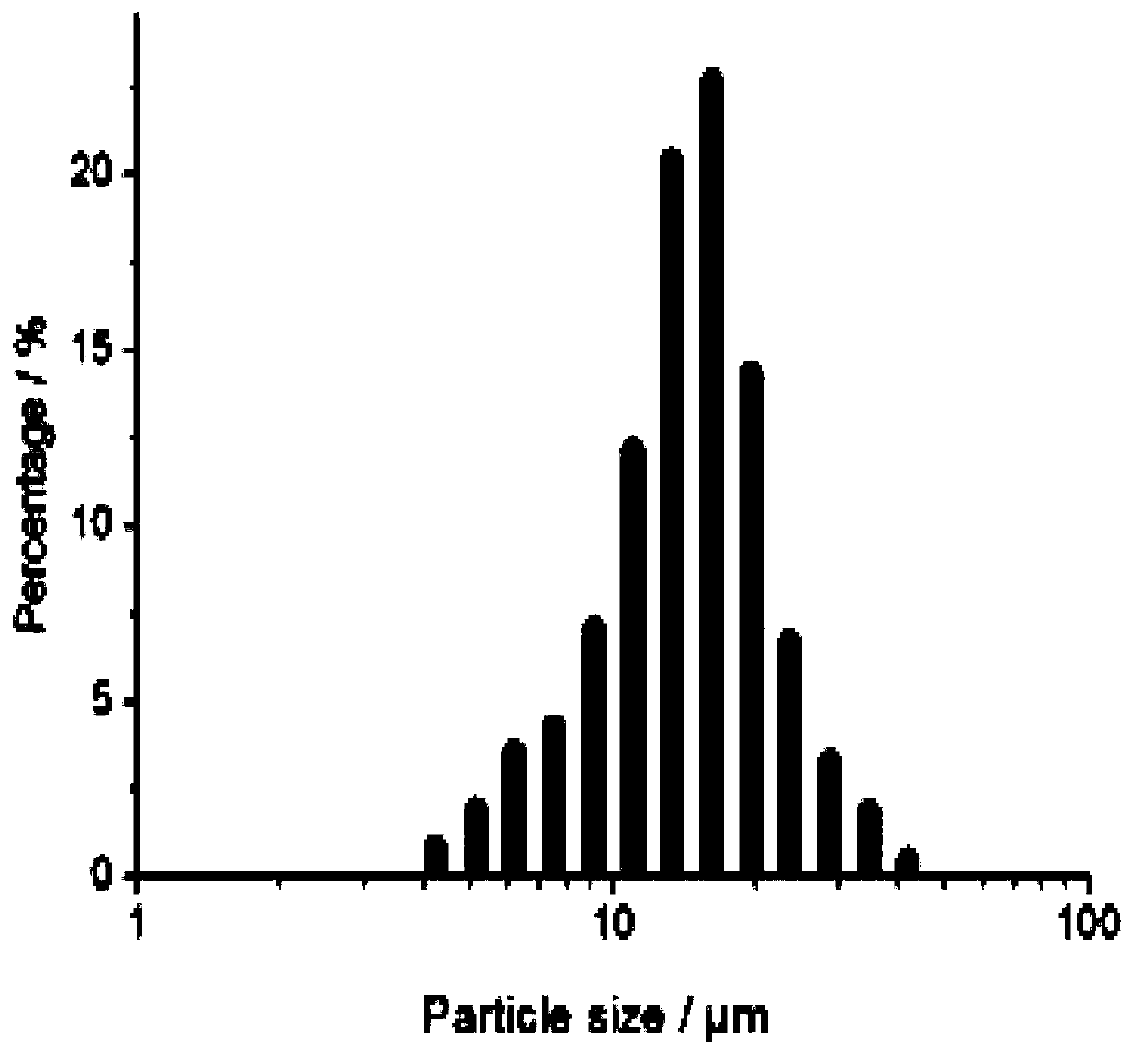

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com