Special fruit bag for pomegranate and preparation method of fruit bag

A fruit bag and pomegranate technology, which is applied in the field of pomegranate fruit bag, special fruit bag for pomegranate and preparation thereof, can solve the problems of reduced fruit skin smoothness, high cost, aggravated fruit, etc. Strength and toughness, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

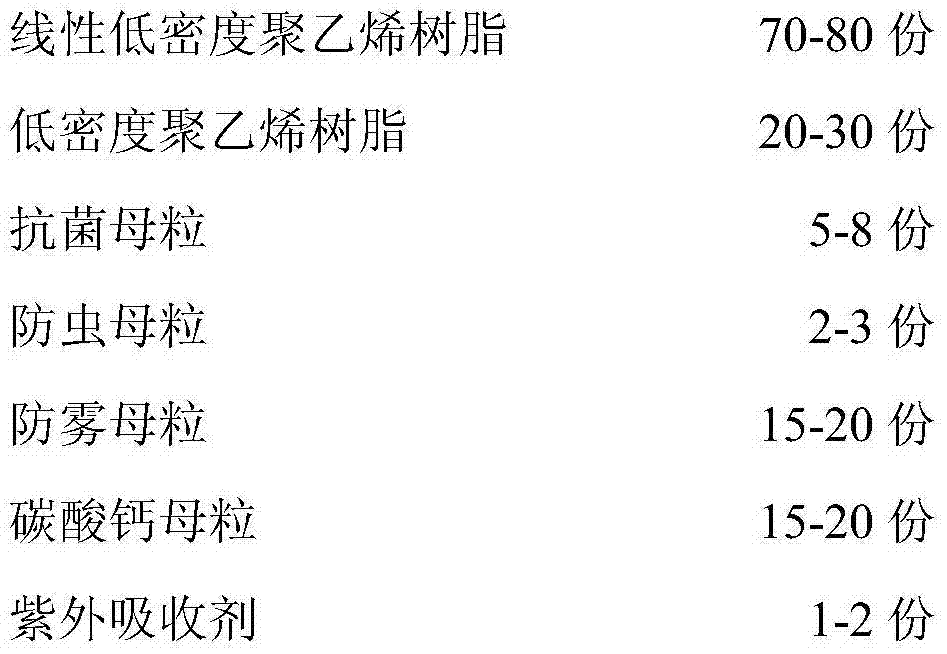

[0031] A special polyethylene fruit bag for pomegranate, its components and parts by weight are:

[0032]

[0033]

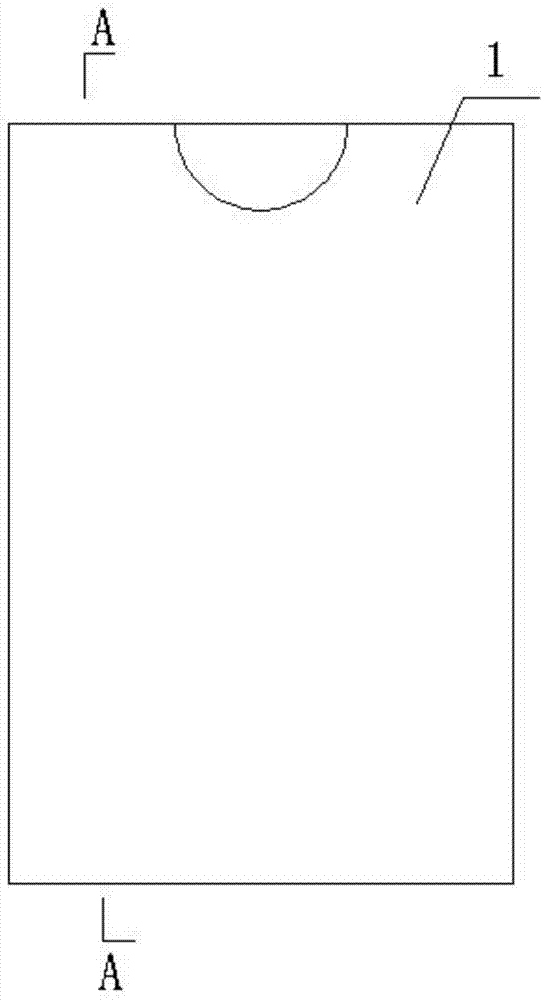

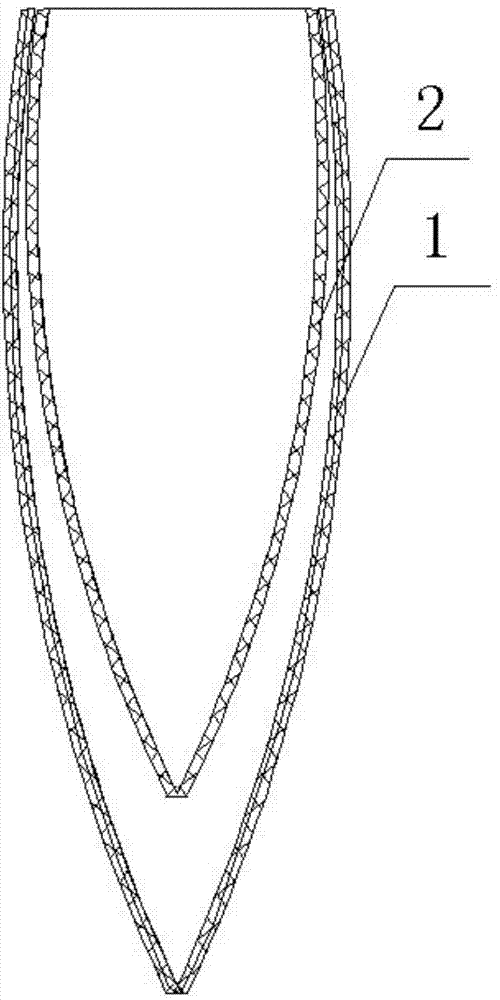

[0034] The preparation method is as follows: Stir and mix the above components and pour them into the film blowing machine, adjust the screw speed to 25r / min, set the temperature of the four stages Ⅰ-Ⅳ to 130°C, 140°C, 145°C, 150°C respectively, and make 20cm long, 15cm wide, 0.02-0.03mm thick film bag.

[0035] The antibacterial masterbatch is 5% antibacterial masterbatch, and the preparation method is as follows: first weigh 280g of 5-chloro-2-methyl-4-isothiazolin-3-one (MIT) and mix it with 115g of thiazolin copper, and then mix Mix the above mixture with 7.6kg of substrate resin (Linear Low Density Polyethylene resin can be used), and stir with a mixer at a speed of 60r / min for 20min to obtain a uniform mixture. Add the compound into a twin-screw extrusion granulator, adjust the granulator speed to 40r / min, and set the temperatures of the four stages...

Embodiment 2

[0042] A special polyethylene fruit bag for pomegranate, its components and parts by weight are:

[0043]

[0044] The preparation method is the same as in Example 1.

[0045] The antibacterial masterbatch is 5% antibacterial masterbatch, and the preparation method is as follows: first weigh 280g of 5-chloro-2-methyl-4-isothiazolin-3-one (MIT) and mix it with 112g of thiazolin copper, and then mix The above mixture was mixed with 7.5 kg of linear low-density polyethylene resin, and stirred with a mixer at a speed of 60 r / min for 20 minutes to obtain a uniform mixture. Add the compound into a twin-screw extrusion granulator, adjust the granulator speed to 40r / min, and set the temperatures of the four stages I-IV to be 120°C, 130°C, 130°C, and 140°C respectively to obtain antibacterial masterbatch;

[0046]The insect-proof masterbatch is 5% insect-proof masterbatch. The preparation method is: take 100g of cypermethrin and 2kg of linear low-density polyethylene resin, stir w...

Embodiment 3

[0050] A special polyethylene fruit bag for pomegranate, its components and parts by weight are:

[0051]

[0052] The preparation method is the same as in Example 1.

[0053] The antibacterial masterbatch is 5% antibacterial masterbatch. The preparation method is as follows: first weigh 280g of 5-chloro-2-methyl-4-isothiazolin-3-one (MIT) and mix it with 167g of thiazolin-copper, and then mix The above mixture was mixed with 8.9 kg of linear low-density polyethylene resin, and stirred with a stirrer at a speed of 60 r / min for 20 minutes to obtain a uniform mixture. Add the compound into a twin-screw extrusion granulator, adjust the granulator speed to 40r / min, and set the temperatures of the four stages I-IV to be 120°C, 130°C, 130°C, and 140°C respectively to obtain antibacterial masterbatch;

[0054] The insect-proof masterbatch is 5% insect-proof masterbatch. The preparation method is: take 100g of cypermethrin and 2kg of linear low-density polyethylene resin, stir wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com