Oxygen-enriched nitrogen supply system for cupola furnace

A supply system, cupola technology, applied in the direction of oxygen preparation, furnace, vertical furnace, etc., can solve the problems of waste of energy and resources, inability to make full use of nitrogen, not easy to burn, full use of nitrogen, waste, etc., to save costs and reduce coke Billy, the effect of raising the combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

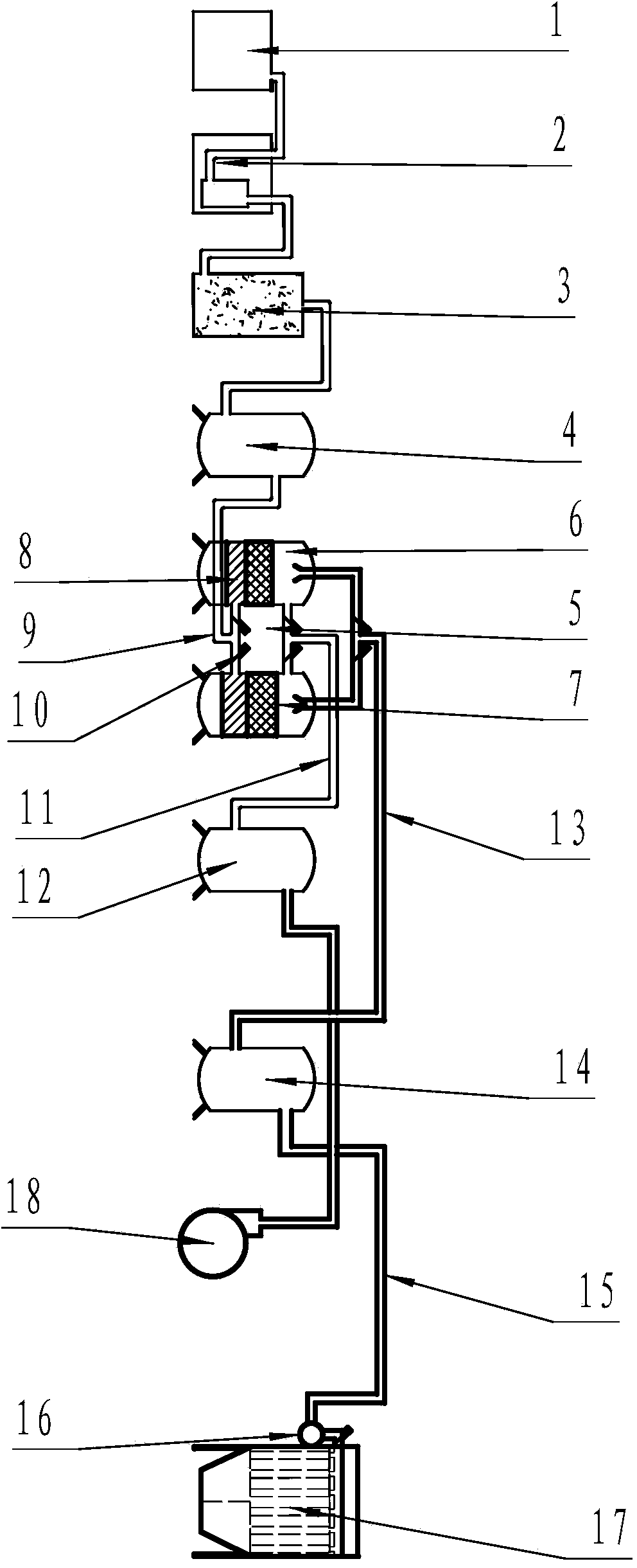

[0015] Example 1, such as figure 1 The shown oxygen-enriched and nitrogen-enriched gas supply system for cupolas includes oxygen-enriched and nitrogen-enriched gas preparation devices and oxygen-enriched and nitrogen-enriched gas supply devices. 1. Cold dryer 2, activated carbon tank 3, compressed air storage tank 4 and oxygen-generating and nitrogen-generating unit 5. The oxygen-generating and nitrogen-generating unit 5 is composed of a pair of adsorption towers 6. The bottom is equipped with activated alumina 8, and the top is equipped with zeolite molecular sieve 7. The lower part of the tower is air-tightly connected to the air pipeline 9 controlled by the solenoid valve 10, and the upper part of the tower is air-tightly connected to the oxygen output controlled by the solenoid valve 10. Pipeline 11, the other end of the oxygen output pipeline 11 is airtightly connected to the oxygen tank 12, characterized in that: the top of the adsorption tower 6 is airtightly connected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com