Metal-supported solid oxide fuel cell and preparation method thereof

A solid oxide, fuel cell technology, used in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve problems such as preparation difficulties and interface atom diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]To 50g of 430 stainless steel powder, add solvent absolute ethanol 7g, butanone 7g, dispersant triethanolamine 4g, plasticizer dibutyl phthalate 1g, binder polyvinyl butyral 4g, pore-forming Ammonium oxalate 20g, mixed by ball milling, the mixed slurry is sieved and vacuum-treated to remove the air in the slurry to obtain the porous alloy layer slurry;

[0043] Add 5g of solvent xylene, 5g of butyl acetate, 1g of dispersant triethanolamine, 1g of plasticizer dibutyl phthalate, binder poly Vinyl butyral 3g, mixed by ball milling, sieving the mixed slurry through a sieve and vacuum treatment to remove the air in the slurry to obtain the electrolyte layer slurry;

[0044] The above two kinds of slurries are tape-casted and dried respectively to obtain the porous alloy layer and the electrolyte layer green body, and then each green body is cut into a green body that meets the size requirements;

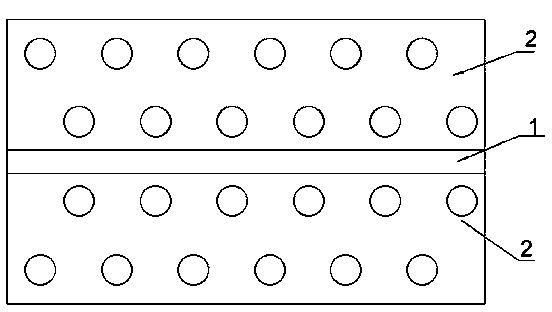

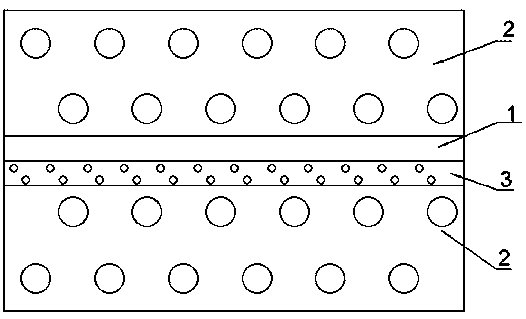

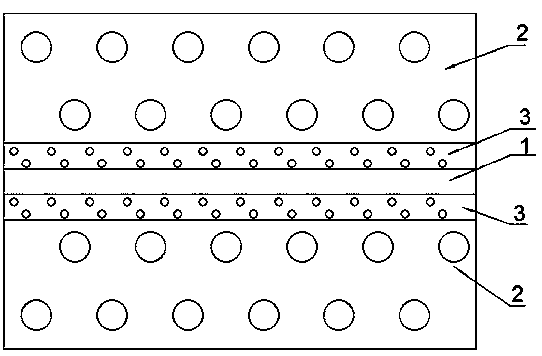

[0045] The porous alloy layer, the electrolyte layer, and the porous alloy lay...

Embodiment 2

[0050] The preparation process and composite layer structure are the same as in Example 1, except that the electrolyte material is zirconia (ScYSZ) co-stabilized by scandium oxide and yttrium oxide, and the cathode side electrode material is Sm 0.5 Sr 0.5 CoO 3-d (SSC) (0≤d0.8 Sr 0.2 VO 3-d (LSV) (0≤d<3).

[0051] The metal-supported solid oxide fuel cell prepared in this example has a maximum power density of 400mW / cm at 650°C 2 .

Embodiment 3

[0053] The preparation process and composite layer structure are the same as in Example 1, except that the electrolyte material is scandium oxide stabilized zirconia (SSZ), and the cathode side electrode materials are Ag and La 0.8 Sr 0.2 MnO 3-d (LSM) (0≤d0.8 Y 0.2 TiO 3-d (SYT) (0≤d<3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com