Method for preparing three-dimensional porous nano composite material of graphene oxide-water soluble polymer

A technology of water-soluble polymers and nanocomposites, which is applied in the field of nanomaterial manufacturing, can solve the problems of limited application range and high energy consumption in preparation, and achieve the effects of simple and easy control of the process, expanding the scope of application, and promoting practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 100mg of graphene oxide and 100mg of polyvinyl alcohol (PVA) as raw materials, dissolve in 20ml of deionized water, heat to 90°C in a water bath, stir for 2 hours and mix well;

[0020] The obtained product was divided into silica gel molds, put into a freezer at -30°C for 24 hours, and then taken out, and the obtained solid was put into a freeze dryer at -50°C, 10Pa for 24 hours of sublimation drying to obtain a cylindrical solid graphene oxide - Three-dimensional porous nanocomposites of water-soluble polymers.

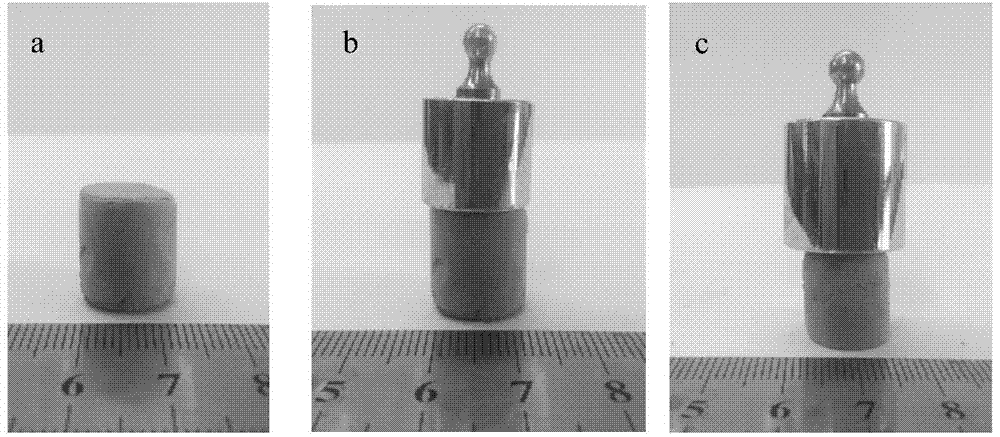

[0021] In order to verify the strength of the composite material, weights of different masses were placed on the 30mg composite material. It can be seen that the structure of the composite material can still remain stable under the weight of 50g, as shown in figure 1 shown.

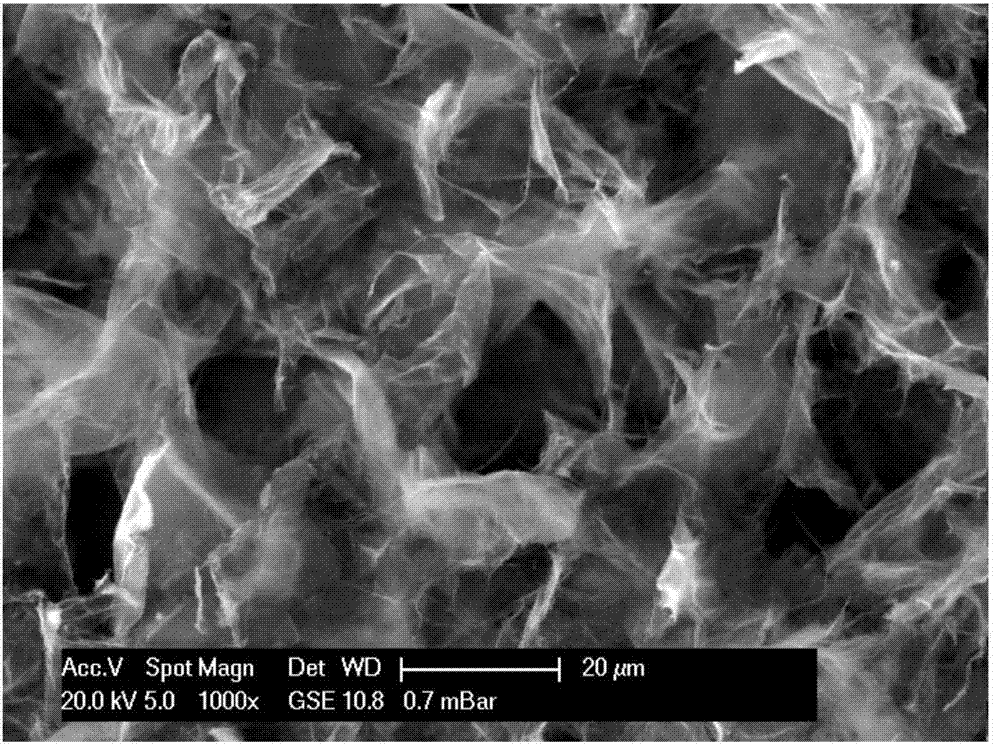

[0022] The composite material was characterized by scanning electron microscopy, and the results were as follows: figure 2 It can be seen that the composite material is a porous ...

Embodiment 2

[0024] Take 100mg of graphene oxide and 20mg of polyethylene glycol (PEG) as raw materials, dissolve in 20ml of deionized water, heat to 70°C in a water bath, stir for 2 hours and mix well;

[0025] The obtained product was divided into silica gel molds, put into a freezer at -30°C for 18 hours, and then taken out, and the obtained solid was put into a freeze dryer at -50°C, 10pa for sublimation drying for 36 hours, and a cylindrical solid graphene oxide was obtained - Three-dimensional porous nanocomposites of water-soluble polymers.

Embodiment 3

[0027] Take 150mg of graphene oxide and 100mg of polyvinylpyrrolidone (PVP) as raw materials, dissolve in 20ml of deionized water, heat to 100°C in a water bath, stir for 1 hour and mix well;

[0028] The obtained product was divided into silica gel molds, put into a freezer at -30°C for 24 hours, and then taken out, and the obtained solid was placed in a freeze dryer at -50°C, 10Pa for 72 hours of sublimation drying to obtain a cylindrical solid graphene oxide - Three-dimensional porous nanocomposites of water-soluble polymers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com