Method for preparing hierarchical porous TiO2/quantum dot composite material

A composite material and quantum dot technology, which is applied in the field of preparation of hierarchical porous TiO2/quantum dot composite materials, can solve the problems of ineffective electron transfer and electron depletion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Hierarchical Porous TiO 2 Preparation of semiconductor powder: add F127 to absolute ethanol (EtOH), stir until the solution is clear, then add TiCl dropwise 4 Continue to stir, the molar ratio of raw materials is F127: EtOH: TiCl 4=1:3397:76, the stirring temperature is 40°C, then put the obtained precursor into a hydrothermal kettle and heat it at 160°C for 16 hours; heat it after filtering and drying, and keep it at 500°C for 240min. Annealed to prepare hierarchically porous TiO 2 Powder.

[0024] (2) Hierarchical Porous TiO 2 / CuInGaS 2 Preparation of Quantum Dot Composite Materials: In the Hierarchical Porous TiO 2 In the powder, add InCl respectively 3 Precursor solution and GaCl 3 Keep the precursor solution under vacuum for 20 minutes, take it out and dry it at 80°C to obtain A; follow the above operation method, and then add CuCl 2 Precursor solution and Na 2 S precursor solution is added to A, the molar ratio of raw materials is TiO 2 : CuCl 2 :I...

Embodiment 2

[0026] (1) GaCl 3 4H 2 O, InCl 3 4H 2 O and Cu 2 Cl (the ratio of the amount of substances is 1:1:1) was added to oleylamine (OA), and stirred at 120°C for 1h;

[0027] (2) Stir sulfur powder (S powder) and OA at 60°C until dissolved;

[0028] (3) After mixing the above two solutions, add them into hexane and stir evenly, and heat them in water at 110°C for 1 hour to obtain CuInGaS 2 Quantum dot solution;

[0029] (4) the hierarchical porous TiO in embodiment 1 2 with CuInGaS 2 Mix the quantum dot solution, stir it in a water bath at 80°C until it becomes viscous, then dry it in a drying oven at 80°C, and finally bake the obtained powder at 500°C for 2 hours, take it out and grind it to obtain a hierarchical porous TiO 2 / CuInGaS 2 Quantum dot composites.

Embodiment 3

[0031] Hierarchical porous TiO in embodiment 1 2 The powder was ground until viscous, coated on a glass slide, and fired at 500°C for 2 hours to obtain a layer of hierarchically porous TiO 2 thin films, which were sequentially immersed in InCl 3 Precursor solution (0.1mol / L), GaCl 3 Precursor solution (0.1mol / L), Na 2 S precursor solution (1mol / L), CuCl 2 Precursor solution (0.1mol / L), the immersion time was 60s, 60s, 120s and 60s, respectively, and the TiO 2 The film was rinsed with deionized water, circulated 10 times, dried and then roasted. The roasting method was to keep warm at 300°C and 500°C for 30min and 60min respectively, and the heating rate was 2°C / min. Finally, a multi-stage film was obtained. Porous TiO 2 / CuInGaS 2 Quantum dot composites.

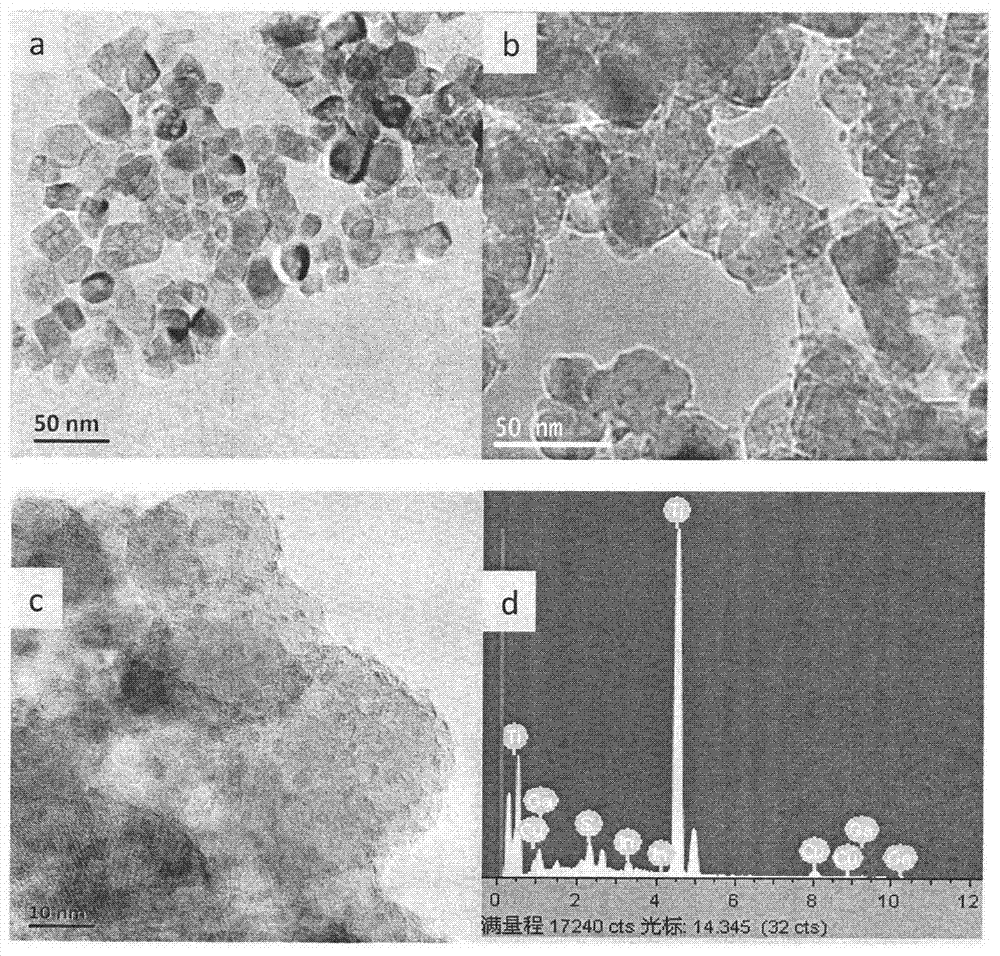

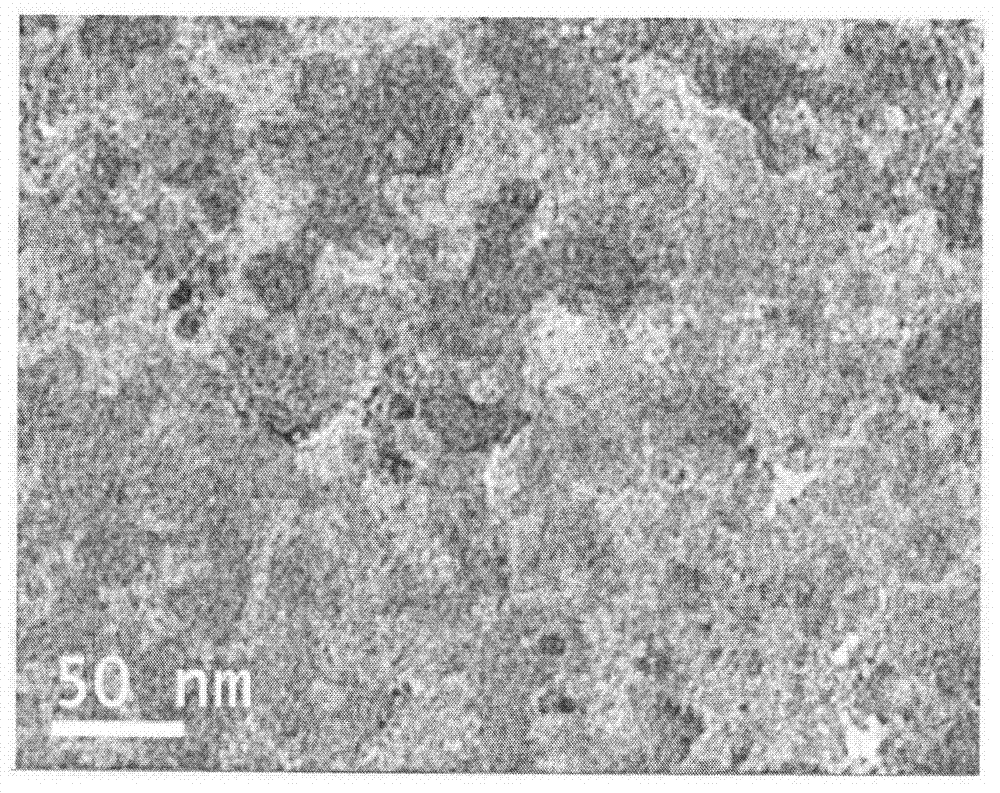

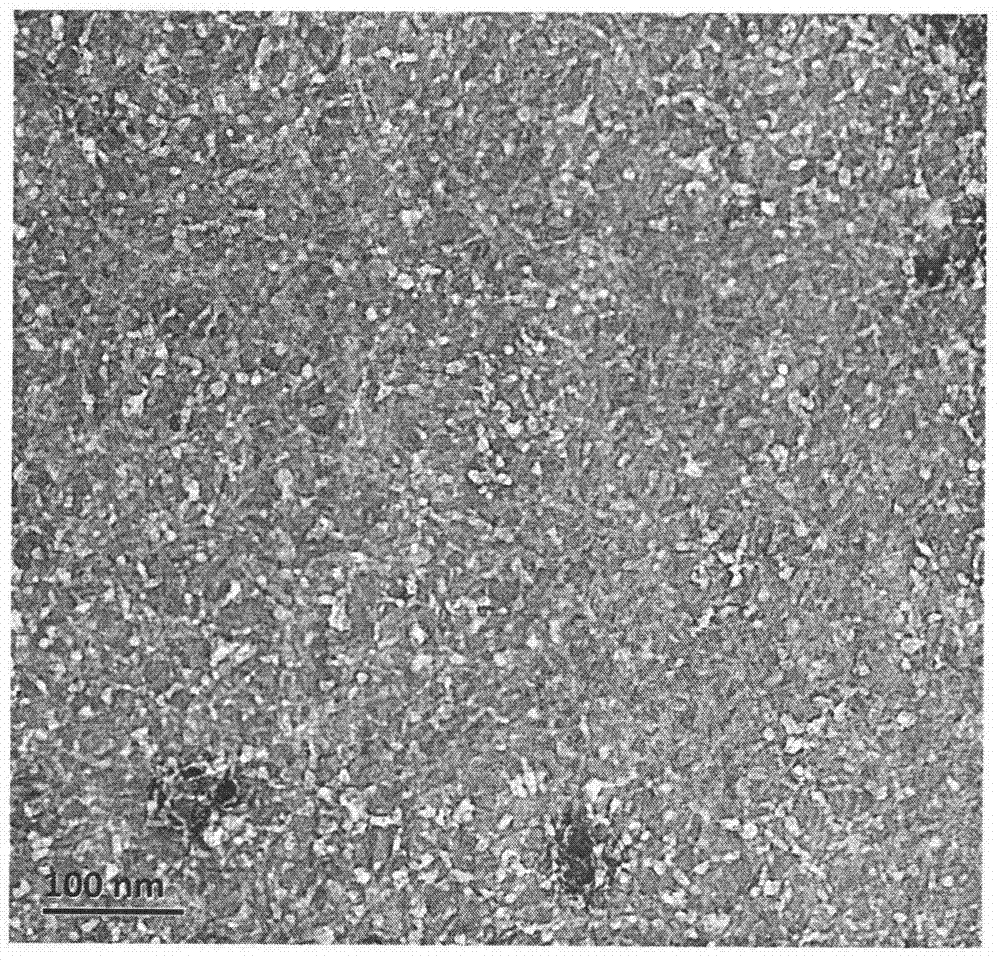

[0032] The effective effects of the present invention can be further described in conjunction with the accompanying drawings. figure 1 a is the hierarchical porous TiO in Example 1 2 Transmission electron microscope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com