Separation method of components of non-peroxide enzyme capable of degrading zearalenone toxins

A zearalenone, non-peroxide technology, applied in the field of microbial applications, can solve the problems of inability to purify non-peroxidase enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] (1) Culture: Inoculate with 1% (v / v) Acinetobacter sp.SM04 suspension (OD 600 =0.6) culture (M2 medium) was cultured in an air-bath shaker at 28°C (150r / min) for 24h, the liquid culture was centrifuged for 10min (8000×g, 4°C), and the supernatant after centrifugation was used 0.22μm membrane filtration, and the filtrate was concentrated 8 times into a crude enzyme solution at 45°C using a vacuum rotary evaporator;

[0073] The formulation of the medium used is as follows:

[0074] M2 medium: 12.5g sodium acetate, 2.5g NH 4 NO 3 , 1.2g K 2 HPO 4 ·3H 2 O, 1g KCl, 0.4g MgSO 4 ·7H 2 O, add 10mL trace element stock solution, add distilled water to make up to 1000mL, adjust the pH to 7.0 after mixing;

[0075] The formula of described trace element stock solution is as follows: 2g / L FeSO 4 ·7H 2 O, 0.5g / L MnSO 4 4H 2 O, 0.4g / L CuSO 4 ·5H 2 O, 0.5g / L CoCl 6 ·6H 2 O and 0.4g / L ZnCl 2 .

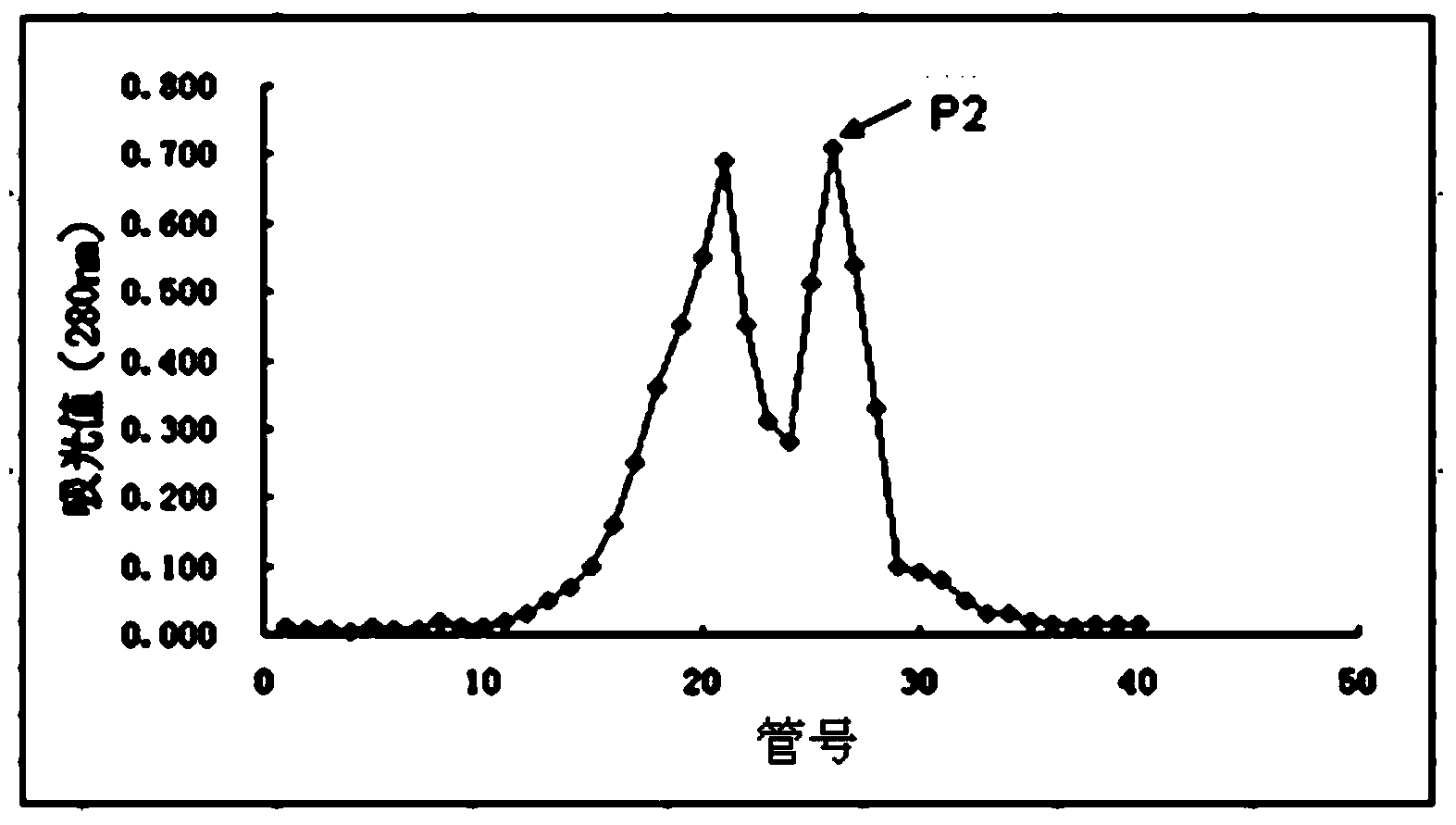

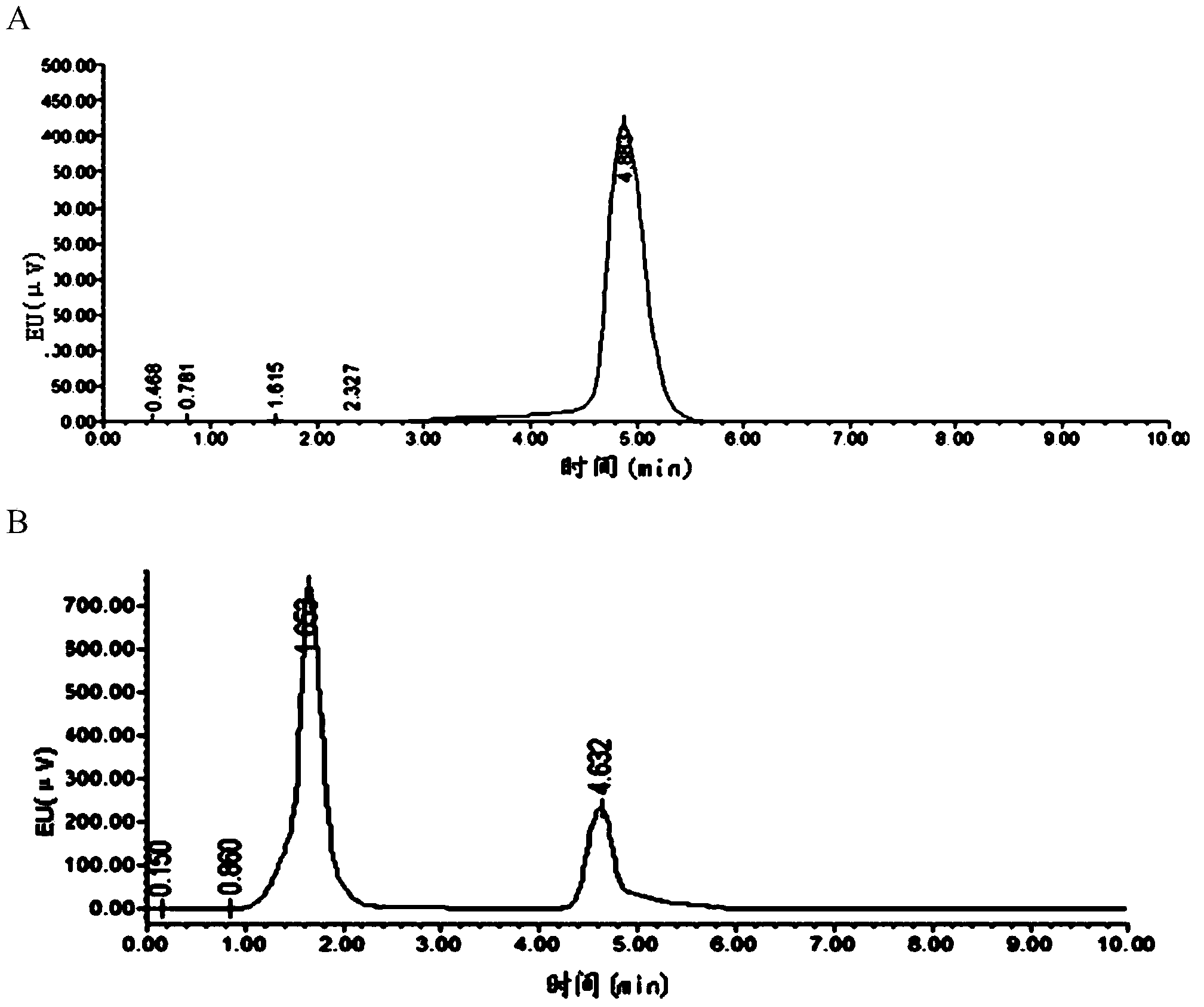

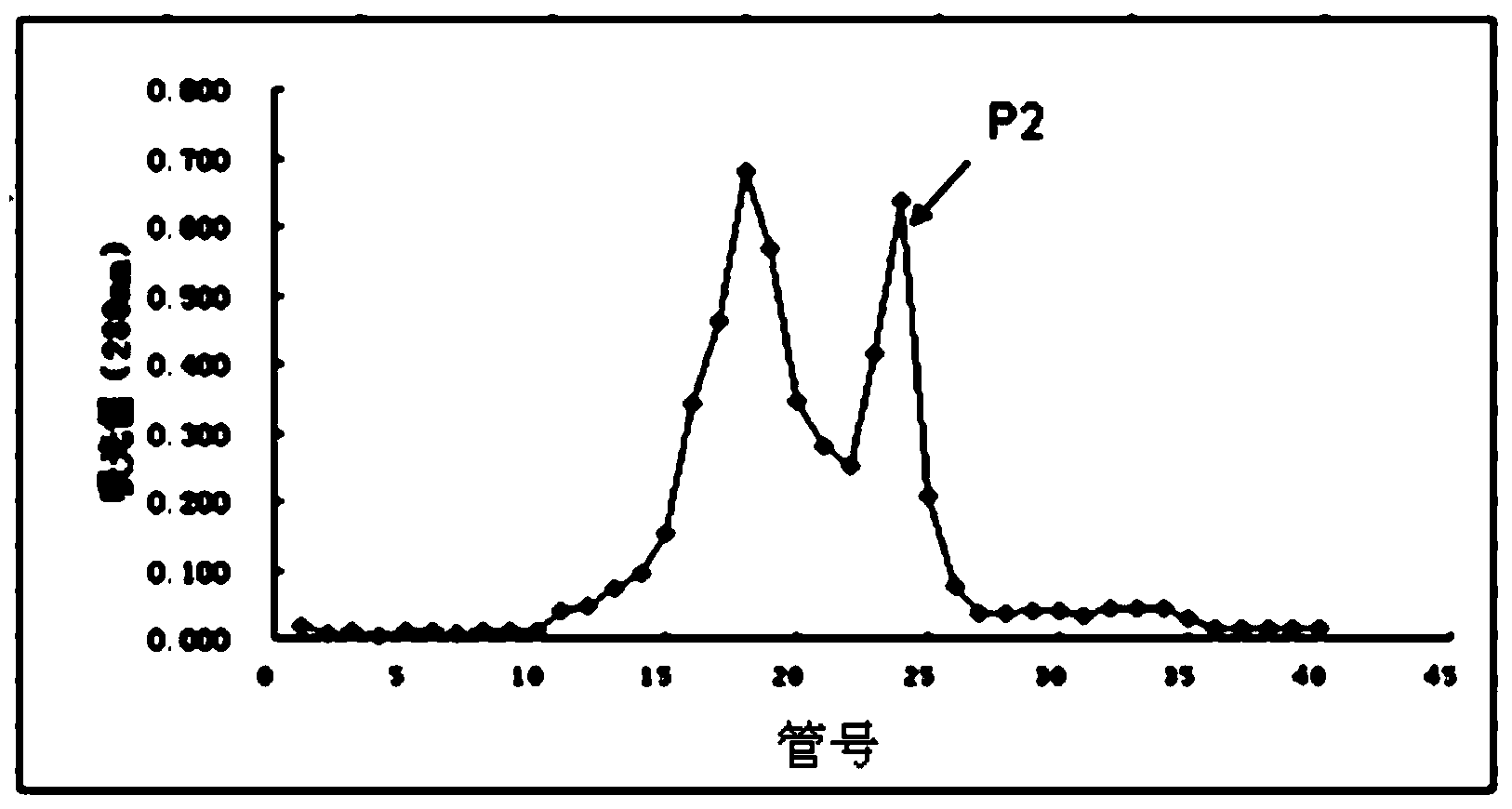

[0076] (2) Add the crude enzyme solution in step (1) to an anionic Sephad...

Embodiment 2

[0084] (1) Culture: inoculate with 2% (v / v) Acinetobacter sp.SM04 suspension (OD 600 =0.8) culture (M2 medium) was cultured in an air-bath shaker at 30°C (180r / min) for 36h to the end of logarithmic growth, and the liquid culture was centrifuged for 12min (9000×g, 5°C). The supernatant was filtered with a 0.22 μm filter membrane, and the filtrate was concentrated 9 times at 50°C using a vacuum rotary evaporator to become a crude enzyme solution;

[0085] The formulation of the medium used is as follows:

[0086] M2 medium: 15g sodium acetate, 2.75g NH 4 NO 3 , 1.35g K 2 HPO 4 ·3H 2 O, 1.25g KCl, 0.5g MgSO 4 ·7H 2 O, add 10mL trace element stock solution, add distilled water to make up to 1000mL, adjust the pH to 7.3 after mixing;

[0087] The formula of the trace element stock solution is the same as that in Example 1-(1).

[0088] (2) Add the crude enzyme solution in step (1) to an anionic Sephadex column DEAE Sephadex A-50 column (2.0cm×15cm), and use phosphoric aci...

Embodiment 3

[0094] (1) Culture: Inoculate with 3% (v / v) Acinetobacter sp.SM04 suspension (OD 600 =1.0) culture (M2 medium) was cultured in an air bath shaker at 28°C (200r / min) for 48h, the liquid culture was centrifuged for 15min (10000×g, 6°C), and the supernatant after centrifugation was used 0.22μm membrane filtration, and the filtrate was concentrated 10 times by a vacuum rotary evaporator at 55°C to form a crude enzyme solution;

[0095] The formulation of the medium used is as follows:

[0096] M2 medium: 17.5g sodium acetate, 3g NH 4 NO 3 , 1.5g K 2 HPO 4 ·3H 2 O, 1.5g KCl, 0.6g MgSO 4 ·7H 2 O, add 10mL trace element stock solution, add distilled water to make up to 1000mL, adjust the pH to 7.5 after mixing;

[0097] The formula of the trace element stock solution is the same as that in Example 1-(1).

[0098] (2) Add the crude enzyme solution in step (1) to an anionic Sephadex column DEAE Sephadex A-50 column (2.0cm×15cm), and use phosphoric acid with pH 7.0, 6.5, 6.0, 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com