Effective method for preparing avermectin

A technology of abamectin and Streptomyces avermitilis, applied in the field of microorganisms, can solve the problems of low yield of production strains, backward fermentation technology and the like, and achieve the effects of improving efficiency and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

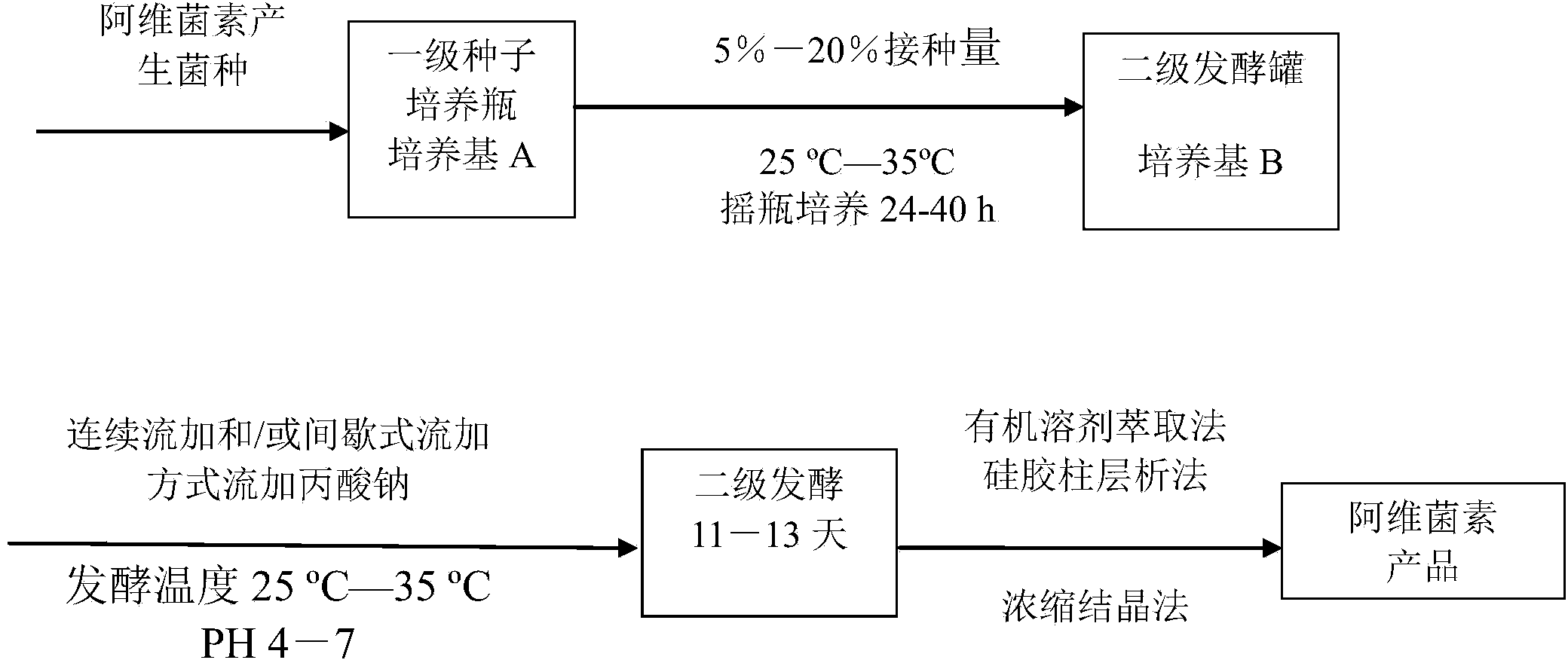

Method used

Image

Examples

Embodiment 1

[0046] Use 10 500mL Erlenmeyer flasks, each containing 150mL medium A (corn starch 3.0%, α-amylase 6u / 100mL, soybean meal powder 0.8%, yeast extract 0.4%, peanut cake powder 1.0%, cobalt chloride 0.3%), Sterilize at 120° C. for 30 minutes, inoculate the activated Streptomyces avermitilis (Streptomyces avermitilis) AW-H1 bacteria liquid after cooling, place at 28° C., and shake the flask for 32 hours. Inoculate the cultured strain solution into a 50L fermenter with 20L sterilized medium B (medium B: corn flour 0.04%, soluble starch 0.01%, cornstarch 14.0% , soybean powder 0.008%, soybean meal powder 2.8%, peanut cake powder 0.006%, yeast extract 0.008%, yeast powder 1.0%, manganese sulfate 0.0072%, ammonium sulfate 0.025%, dipotassium hydrogen phosphate 0.0008%, cobalt chloride 0.002%, Sodium chloride 0.0003%, sodium molybdate 0.023%, α-amylase 28u / 100mL, calcium carbonate 0.08%), at 27°C-32°C, aeration and stirring fermentation for 8-20 hours, with 0.01-1.0L / Sodium propionat...

Embodiment 2

[0051] Use 12 500mL Erlenmeyer flasks, each containing 150mL medium A (corn starch 4.0%, α-amylase 8u / 100mL, soybean meal powder 1.0%, yeast extract 0.4%, peanut cake powder 0.8%, cobalt chloride 0.2%), Sterilize at 120° C. for 30 minutes, inoculate the activated Streptomyces avermitilis (Streptomyces avermitilis) AW-H1 bacteria liquid after cooling, place at 28° C., and shake the flask for 32 hours. Inoculate the cultured strain solution into a 50L fermenter with 20L sterilized medium B (medium B: 0.08% corn flour, 0.02% soluble starch, 12.0% cornstarch) , soybean powder 0.02%, soybean meal powder 3.0%, peanut cake powder 0.01%, yeast extract 0.01%, yeast powder 1.5%, manganese sulfate 0.0024%, ammonium sulfate 0.02%, dipotassium hydrogen phosphate 0.001%, cobalt chloride 0.0025%, Sodium chloride 0.001%, sodium molybdate 0.025%, α-amylase 30u / 100mL, calcium carbonate 0.08%), at 27°C-32°C, aeration and stirring fermentation for 8-20 hours, intermittent feeding of propionic aci...

Embodiment 3

[0056] Use 10 500mL Erlenmeyer flasks, each containing 150mL medium A (corn starch 4.0%, α-amylase 8u / 100mL, soybean meal powder 1.0%, yeast extract 0.5%, peanut cake powder 1.0%, cobalt chloride 0.2%), Sterilize at 120°C for 30 minutes, inoculate the activated Streptomyces avermitilis AW-12 (preserved in our laboratory) bacterial solution after cooling, place at 28°C, and shake the flask for 32 hours. Inoculate the cultured strain solution into a 50L fermenter with 20L sterilized medium B (medium B: 0.06% corn flour, 0.008% soluble starch, 16.0% cornstarch, Soybean powder 0.01%, soybean meal powder 3.0%, peanut cake powder 0.02%, yeast extract 0.02%, yeast powder 1.5%, manganese sulfate 0.003%, ammonium sulfate 0.025%, dipotassium hydrogen phosphate 0.002%, cobalt chloride 0.002%, chlorine Sodium chloride 0.0008%, sodium molybdate 0.023%, α-amylase 40u / 100mL, calcium carbonate 0.1%), at 27°C-32°C, aeration and stirring fermentation for 8-20 hours, then 0.01-1.0L / h Sodium pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com